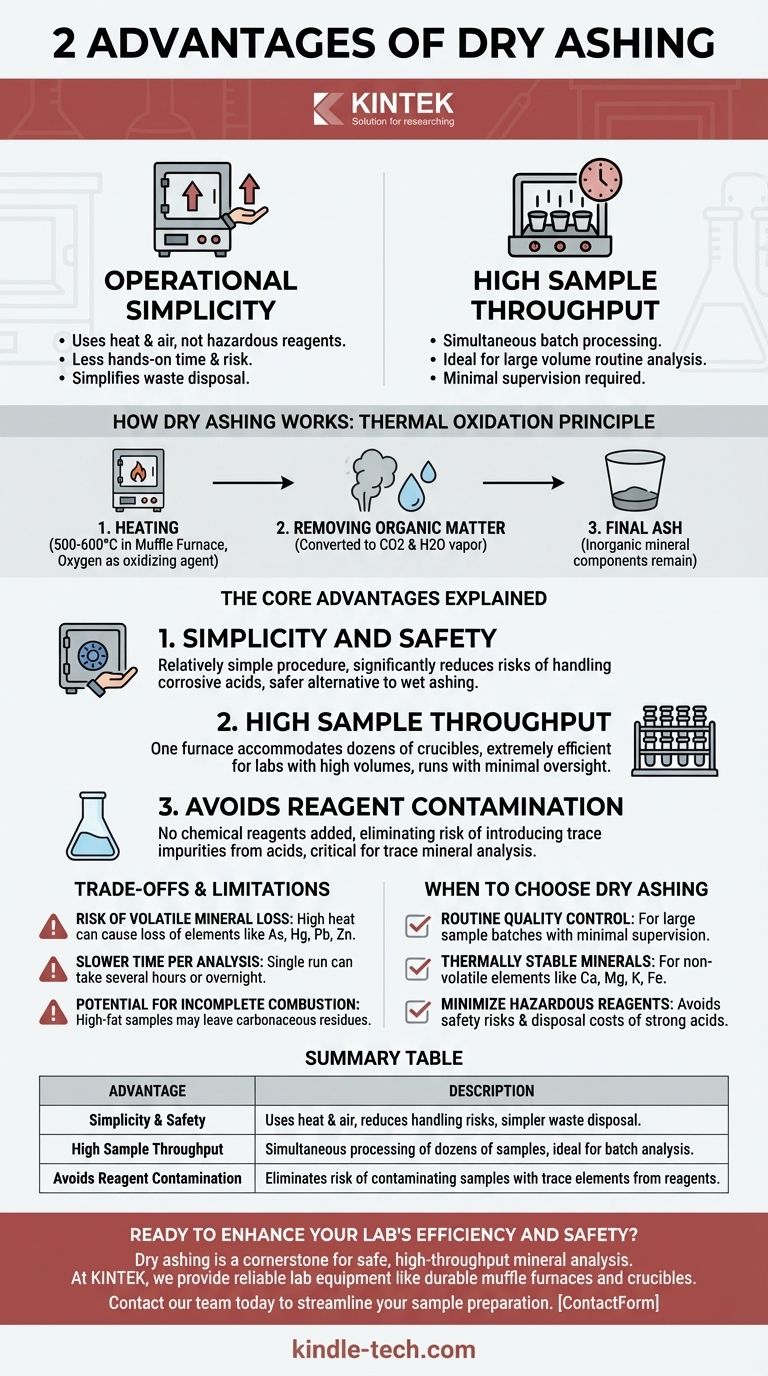

The primary advantages of dry ashing are its operational simplicity and its capacity for high sample throughput. This method requires minimal use of hazardous reagents and allows a technician to process many samples simultaneously with little hands-on supervision, making it a highly efficient choice for many routine analyses.

Choosing a sample preparation technique is a critical decision in analytical chemistry. Dry ashing stands out as the preferred method when your goals are operational efficiency and safety, particularly for large batches of samples where the target minerals are not volatile.

How Dry Ashing Works: The Principle of Thermal Oxidation

Dry ashing is a process of decomposition that uses high heat and ambient air to eliminate the organic matter from a sample, leaving behind only the inorganic, mineral components.

Heating in the Presence of Oxygen

The sample is placed in a muffle furnace and heated to high temperatures, typically between 500 and 600°C. The oxygen in the air within the furnace acts as the oxidizing agent.

Removing Organic Matter

At these temperatures, all organic compounds (materials based on carbon) are burned off. They are converted into gases like carbon dioxide and water vapor, which are then vented from the system.

The Final Ash

The material that remains after this process is complete is called ash. This ash consists of the inorganic mineral components of the original sample, typically in the form of oxides, sulfates, phosphates, and chlorides.

The Core Advantages Explained

The benefits of dry ashing stem directly from its simple and straightforward methodology compared to its primary alternative, wet ashing.

Advantage 1: Simplicity and Safety

Dry ashing is a relatively simple procedure that requires less hands-on time from an analyst. Unlike wet ashing, which relies on potent and hazardous acids, dry ashing primarily uses heat and air. This significantly reduces the risks associated with handling corrosive chemicals and simplifies waste disposal.

Advantage 2: High Sample Throughput

A single muffle furnace can accommodate a large number of crucibles at once. This allows for the simultaneous processing of dozens of samples, making it an extremely efficient method for laboratories that handle a high volume of routine quality control tests. Once the furnace program is started, it requires minimal supervision.

Advantage 3: Avoids Reagent Contamination

Because no chemical reagents are added to the sample, there is no risk of contaminating the sample with trace elements that might be present in acids or oxidizing agents. This can be a critical advantage when performing trace mineral analysis where high purity is essential.

Understanding the Trade-offs and Limitations

No technique is perfect. To use dry ashing effectively, you must understand its inherent limitations.

The Risk of Volatile Mineral Loss

This is the most significant drawback of dry ashing. The high temperatures can cause volatile minerals and trace elements (such as arsenic, mercury, lead, and zinc) to vaporize and be lost. This leads to an underestimation of their content and makes the method unsuitable for analyzing these specific elements.

Slower Time Per Analysis

While throughput for a large batch is high, the actual time for a single dry ashing run can be very long, often taking several hours or even overnight. Wet ashing, while more labor-intensive, can often be completed more quickly for a small number of samples.

Potential for Incomplete Combustion

For samples with very high fat content, the organic matter may not combust completely, sometimes leaving behind carbonaceous residues. This can lead to an overestimation of the final ash content.

When to Choose Dry Ashing

Your analytical goal should always dictate your choice of method. Use these guidelines to make an informed decision.

- If your primary focus is routine quality control on large sample batches: Dry ashing is highly efficient and cost-effective due to its capacity for batch processing and minimal need for supervision.

- If your analysis targets thermally stable, non-volatile minerals: For elements like calcium, magnesium, potassium, and iron, dry ashing is a reliable and straightforward method.

- If your priority is to minimize the use of hazardous chemical reagents: Dry ashing avoids the safety risks, procurement challenges, and disposal costs associated with the strong acids required for wet ashing.

Ultimately, selecting dry ashing is a strategic decision that prioritizes operational efficiency and safety for the analysis of thermally stable minerals.

Summary Table:

| Advantage | Description |

|---|---|

| Simplicity & Safety | Uses heat and air instead of hazardous acids, reducing handling risks and waste disposal complexity. |

| High Sample Throughput | Allows simultaneous processing of dozens of samples in a muffle furnace, ideal for routine batch analysis. |

| Avoids Reagent Contamination | Eliminates risk of contaminating samples with trace elements from chemical reagents, ensuring analytical purity. |

Ready to enhance your lab's efficiency and safety?

Dry ashing is a cornerstone technique for high-throughput, safe mineral analysis. At KINTEK, we specialize in providing the reliable lab equipment—like durable muffle furnaces and crucibles—you need to implement this method effectively.

Our experts can help you select the perfect solution for your specific application, whether you're in food science, pharmaceuticals, or environmental testing. Contact our team today to discuss how our products can streamline your sample preparation and deliver accurate results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a lab oven and a muffle furnace? A Guide to Temperature Applications

- What is the function of a high-temperature muffle furnace for duplex stainless steel? Optimize Alloy Performance

- What is the safety of a muffle furnace? Ensuring Secure Operation with Modern Design and Protocols

- How do high-temperature industrial furnaces ensure the quality of aluminide diffusion coatings? Precision Thermal Control

- What are the process functions of a sintering furnace in carbon xerogel synthesis? Engineering Superior Supercapacitors

- What is the role of a laboratory oven in PEO ceramic coating pretreatment? Ensure Precise Electrolyte Stabilization

- What is the purpose of ashing? To Quantify Minerals or Prepare Samples for Analysis

- How do you check the temperature of a muffle furnace? A Guide to Precise Monitoring