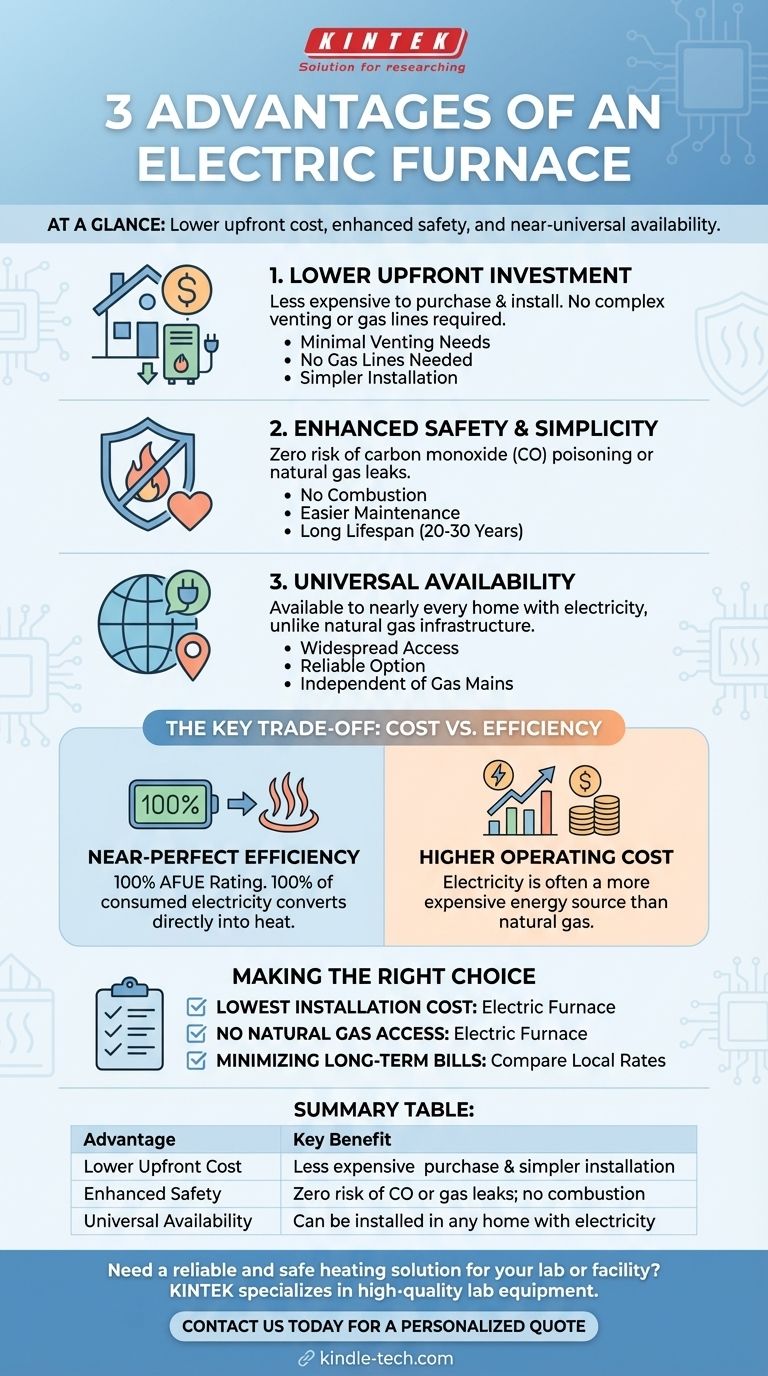

At a glance, the three primary advantages of an electric furnace are its lower upfront cost, enhanced safety profile, and near-universal availability. Unlike gas furnaces, they do not require complex venting or a dedicated gas line, making installation simpler and cheaper in almost any home with electricity.

The core decision between an electric and gas furnace is not about which is "better," but about balancing a lower initial investment against a potentially higher long-term operating cost. While an electric furnace is simpler and safer, its economic viability depends entirely on your local electricity rates.

The Core Advantages Explained

An electric furnace's benefits stem from its fundamental simplicity. By using electricity to generate heat directly, it bypasses the complexities and risks associated with fuel combustion.

Lower Upfront Investment

Electric furnaces are consistently less expensive to purchase and install than their gas-powered counterparts.

The installation is less invasive and requires less specialized labor. There is no need to run gas lines, and venting requirements are minimal because there are no exhaust gases to expel.

Enhanced Safety and Simplicity

The greatest safety benefit is the complete elimination of combustion. This means there is zero risk of carbon monoxide (CO) poisoning or natural gas leaks in your home.

This simplicity also translates to easier maintenance. With no burners to clean, gas valves to check, or heat exchangers that could crack, annual service is typically faster and less complex. The units also tend to have a very long lifespan, often lasting 20 to 30 years.

Universal Availability

Nearly every home in the country is connected to the electrical grid. Natural gas infrastructure, however, is not available everywhere, particularly in rural areas or even certain urban neighborhoods.

This makes an electric furnace a reliable and often default option for any location with electricity, removing the dependency on proximity to a gas main.

Understanding the Key Trade-off: Cost vs. Efficiency

The most critical factor to evaluate is the relationship between an electric furnace's high efficiency and the high cost of the energy it consumes.

Near-Perfect Efficiency

Electric resistance heating is a remarkably efficient process. An electric furnace has an AFUE (Annual Fuel Utilization Efficiency) rating of 100%.

This means 100% of the electricity it consumes is converted directly into usable heat. In contrast, even high-efficiency gas furnaces lose some heat through exhaust venting, with AFUE ratings typically between 90% and 98%.

The High Cost of Electricity

The trade-off is that electricity is often a more expensive energy source than natural gas per unit of heat produced (measured in BTUs).

So, while none of the energy is wasted in the conversion process, the cost of that initial energy can be significantly higher. This is the single most important factor determining your monthly heating bills.

Why This Matters for Your Bill

A furnace's efficiency rating only tells you how well it converts fuel into heat; it doesn't tell you the cost of that fuel.

Therefore, a 100% efficient electric furnace can easily result in a higher heating bill than a 95% efficient gas furnace if local natural gas prices are substantially lower than electricity rates.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your priorities, your home's location, and your long-term budget.

- If your primary focus is the lowest possible installation cost: An electric furnace is almost always the most affordable option upfront.

- If you live in an area without natural gas access: An electric furnace is a straightforward, safe, and highly reliable heating solution.

- If your goal is minimizing long-term heating bills in a cold climate: You must compare your local electricity and gas rates; a high-efficiency gas furnace or an electric heat pump will often be more economical over the life of the system.

By balancing the low initial cost against the long-term operating expense, you can confidently select the heating system that truly serves your financial and practical needs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Lower Upfront Cost | Less expensive purchase & simpler installation with no gas lines or complex venting. |

| Enhanced Safety | Zero risk of carbon monoxide poisoning or gas leaks due to no combustion. |

| Universal Availability | Can be installed in any home with electricity, independent of natural gas infrastructure. |

Need a reliable and safe heating solution for your lab or facility? KINTEK specializes in providing high-quality lab equipment, including efficient and safe heating systems. Our experts can help you select the perfect furnace to meet your specific needs and budget. Contact us today to discuss your project and get a personalized quote!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- What is an electric muffle furnace? Achieve Unmatched Thermal Purity and Uniformity

- What is the use of electric muffle furnace? Achieve Pure, High-Temperature Processing

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing