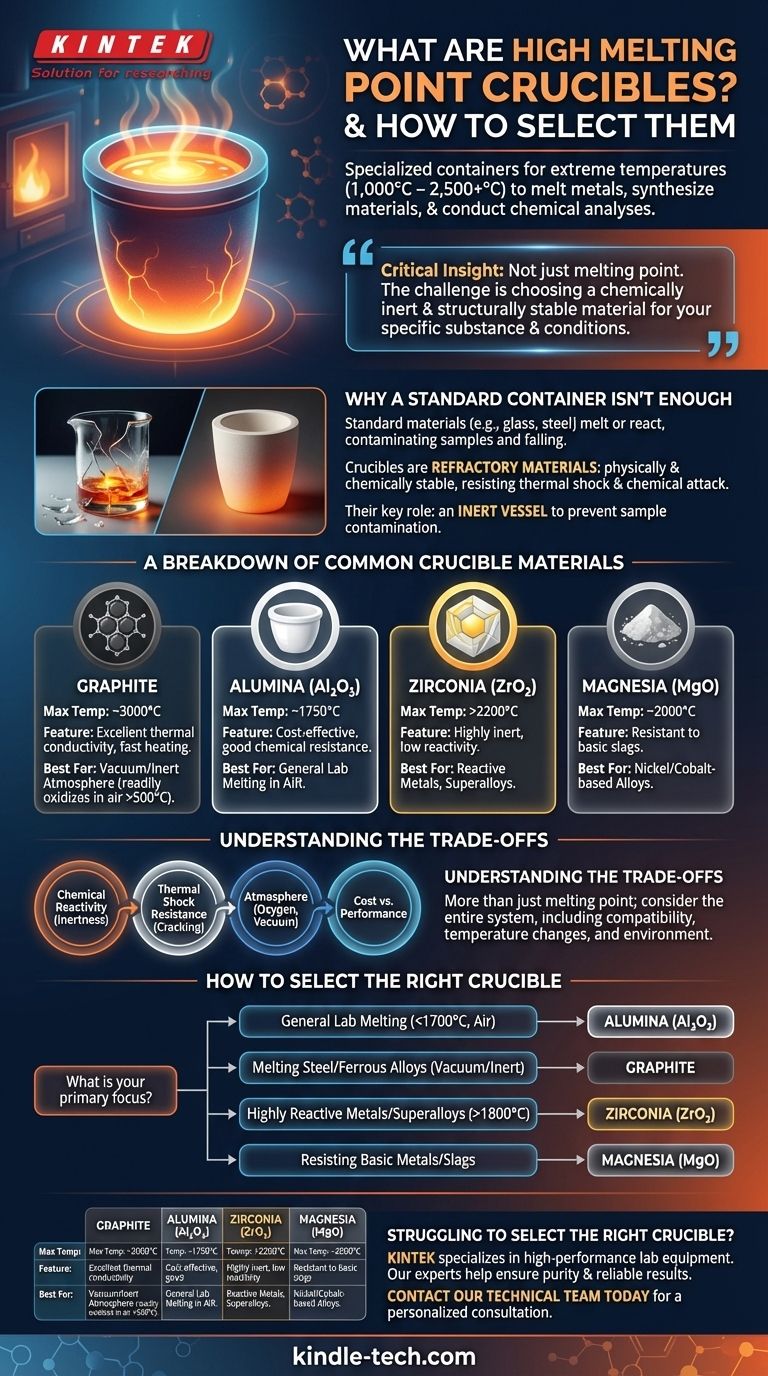

At their core, high melting point crucibles are specialized containers engineered to withstand extreme temperatures, typically ranging from 1,000°C (1,832°F) to over 2,500°C (4,532°F). They are essential for processes like melting metals, synthesizing materials, and conducting high-temperature chemical analyses. The choice of crucible material—such as alumina, zirconia, graphite, or even platinum—is dictated by the specific temperature, chemical environment, and material being processed.

The critical insight is that a crucible's melting point is only the starting point. The true challenge is selecting a material that remains chemically inert and structurally stable in contact with your specific substance and under your specific process conditions, preventing both sample contamination and catastrophic failure.

Why a Standard Container Isn't Enough

In high-temperature work, the goal is to contain a substance without introducing impurities or having the container fail. Standard materials like glass or steel simply cannot withstand the required heat and would melt or react, destroying the experiment.

The Role of a Refractory Material

High-temperature crucibles are made from refractory materials. A refractory is a substance that is physically and chemically stable at high temperatures.

This stability is not just about not melting. It also includes resistance to thermal shock (cracking from rapid temperature changes) and chemical attack from the contents.

Preventing Contamination

A key function of a crucible is to act as an inert vessel. If the crucible material reacts with the molten metal or chemical inside it, the sample becomes contaminated and its properties are altered. This is a critical failure in metallurgy, research, and manufacturing.

A Breakdown of Common Crucible Materials

The material you choose is the single most important decision. Each has a distinct profile of strengths, weaknesses, and ideal use cases.

Graphite Crucibles

Graphite offers extremely high temperature resistance (up to 3,000°C) and excellent thermal conductivity, which allows for fast and even heating.

However, it readily oxidizes in the presence of air at temperatures above 500°C. Therefore, graphite crucibles are almost exclusively used in vacuum or inert gas (like argon) furnaces.

Alumina (Aluminum Oxide, Al₂O₃) Crucibles

Alumina is a versatile ceramic workhorse, stable up to around 1,750°C. It is relatively low-cost and offers good resistance to chemical attack.

It is an excellent choice for melting a wide range of metals and glasses in an air atmosphere. It is one of the most common crucibles found in a materials lab.

Zirconia (Zirconium Dioxide, ZrO₂) Crucibles

Zirconia boasts a very high melting point, with service temperatures often exceeding 2,200°C. It is particularly useful for its low reactivity with certain molten metals.

It is often chosen for melting superalloys and platinum group metals, where the extreme inertness of zirconia is required to prevent contamination.

Magnesia (Magnesium Oxide, MgO) Crucibles

Magnesia crucibles are highly resistant to basic slags and are specifically used for melting metals like nickel and cobalt-based alloys.

Their primary advantage is superior performance in contact with these specific materials, where alumina or zirconia might react.

Understanding the Trade-offs: More Than Just Melting Point

Selecting a crucible based solely on its melting point is a common and costly mistake. You must consider the entire system.

Chemical Reactivity and Inertness

A high melting point is useless if the crucible reacts with your sample. For example, you would not use a silica-based (quartz) crucible to melt titanium, as the titanium would aggressively react with and reduce the silica. You must check the chemical compatibility between your sample and the crucible.

Thermal Shock Resistance

This measures how well a material withstands rapid changes in temperature without cracking. Ceramics like alumina can be prone to thermal shock, requiring carefully controlled heating and cooling rates. Materials like graphite have much better thermal shock resistance.

Atmosphere and Environment

The furnace environment dictates material choice. As mentioned, graphite cannot be used in an oxygen-rich atmosphere at high temperatures. Conversely, some non-oxide ceramics may degrade in air but perform well in a vacuum.

Cost vs. Performance

There is a massive cost difference between materials. A clay-graphite crucible might cost a few dollars, while a crucible made of pure platinum can cost thousands. The goal is to select the least expensive material that meets all of your technical requirements without compromise.

How to Select the Right Crucible

Use this guide to steer your decision based on your primary objective.

- If your primary focus is general-purpose lab melting below 1700°C in air: Start with an Alumina (Al₂O₃) crucible. It offers the best balance of performance and cost for a wide range of applications.

- If you are melting steel or other ferrous alloys in a vacuum or inert atmosphere: A clay-graphite or pure graphite crucible is the industry standard due to its cost-effectiveness and thermal performance.

- If you are working with highly reactive metals or superalloys above 1800°C: You must invest in a specialty ceramic like stabilized Zirconia (ZrO₂) to ensure minimal contamination.

- If your primary focus is resisting basic metals and slags (e.g., nickel-based alloys): A Magnesia (MgO) crucible is the chemically superior choice for this specific application.

Choosing the right crucible is an exercise in understanding your entire process, not just a single temperature value.

Summary Table:

| Material | Max Temperature | Key Feature | Best For |

|---|---|---|---|

| Graphite | ~3000°C | Excellent thermal conductivity | Vacuum/inert atmosphere melting |

| Alumina (Al₂O₃) | ~1750°C | Cost-effective, versatile | General-purpose lab melting in air |

| Zirconia (ZrO₂) | >2200°C | Highly inert, low reactivity | Reactive metals, superalloys |

| Magnesia (MgO) | ~2000°C | Resistant to basic slags | Nickel/cobalt-based alloys |

Struggling to select the right crucible for your high-temperature process? KINTEK specializes in high-performance lab equipment, including a comprehensive range of crucibles made from alumina, graphite, zirconia, and more. Our experts can help you choose the perfect crucible to ensure purity, prevent contamination, and achieve reliable results in your specific application. Contact our technical team today for a personalized consultation and elevate your high-temperature processes with KINTEK.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

People Also Ask

- What are the advantages of customized titanium alloy crucibles? Ensure Precision in Liquid Sodium Corrosion Research

- Why are alumina crucibles selected for FeCrAl coating experiments? Ensure Data Fidelity at High Temperatures

- What are the advantages of using a graphite crucible? Maximize Purity and Thermal Stability in Magnesium Reduction

- Do I need different crucibles for different metals? Ensure Safety and Purity in Your Metal Melting

- What are the dual functions of a high-strength stainless steel crucible in a liquid metal electrochemical corrosion cell?

- Why is a platinum (Pt) sample crucible preferred for TGA of LCLA composite materials? Ensure Superior Data Integrity

- What are the disadvantages of crucible furnace? Understanding the Trade-offs in Metal Melting

- How do you prevent the crucible from cracking during heating? Master Thermal Shock Prevention