In short, sample preparation is a multi-stage process designed to transform raw, often powdered materials into a solid, uniform specimen suitable for testing or use. The core stages involve reducing particle size and mixing (milling), shaping and compacting the powder (pressing), and applying heat to fuse the particles into a dense solid (sintering).

The fundamental goal of sample preparation is not just to follow a recipe, but to precisely control the material's final microstructure. Each step, from grinding to heating, is a deliberate action to achieve a desired density, grain size, and chemical purity.

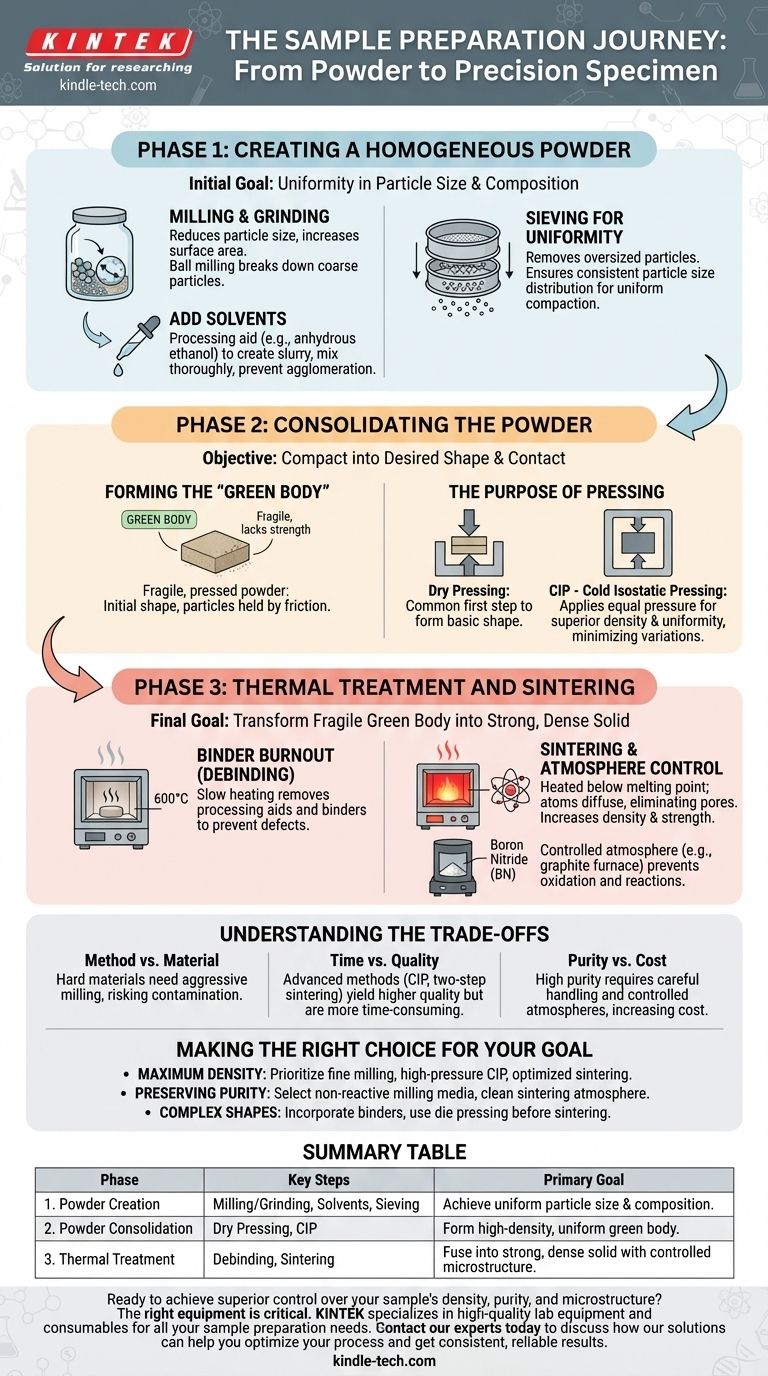

Phase 1: Creating a Homogeneous Powder

The quality of your final sample is determined at the very beginning. The initial goal is to create a powder that is as uniform as possible in both particle size and chemical composition.

Why Milling and Grinding?

Milling is the primary method for particle size reduction. Techniques like ball milling use grinding media to break down coarse particles, which dramatically increases the surface area.

This fine, uniform powder is crucial for effective sintering later in the process.

The Role of Solvents

Often, a liquid like anhydrous ethanol is added during milling. This is not a chemical reactant but a processing aid.

It helps create a slurry, ensuring all constituent powders are mixed thoroughly and preventing the fine particles from clumping back together (agglomeration).

Sieving for Uniformity

After milling and drying, the powder is passed through a sieve. This step removes any oversized particles or agglomerates that were not broken down during milling.

The result is a powder with a controlled and consistent particle size distribution, which is essential for uniform compaction.

Phase 2: Consolidating the Powder

Once you have a uniform powder, the next objective is to compact it into a desired shape with as much particle-to-particle contact as possible.

Forming the "Green Body"

The initial, fragile part formed from the powder is called a green body. It has the desired shape but lacks mechanical strength, as the particles are only held together by friction.

The Purpose of Pressing

To increase the density of the green body, pressure is applied. Dry pressing is a common first step to form the basic shape.

For superior density and uniformity, Cold Isostatic Pressing (CIP) is often used. This technique applies pressure equally from all directions, minimizing density variations within the sample.

Phase 3: Thermal Treatment and Sintering

This final phase uses heat to transform the fragile green body into a strong, dense, solid part.

Binder Burnout (Debinding)

The sample is first heated slowly to a moderate temperature, such as 600°C. This initial heating stage allows any processing aids, solvents, or binders to safely evaporate or burn out.

Rushing this step can cause defects like cracks or blisters in the final sample.

What is Sintering?

Sintering is the critical step where the sample is heated to a high temperature, below its melting point. At this temperature, the atoms diffuse across the boundaries of the particles, fusing them together.

This process eliminates the pores between particles, causing the sample to shrink and its density and strength to increase significantly. Advanced methods like two-step sintering can be used to achieve high density while limiting grain growth.

Controlling the Sintering Atmosphere

The environment inside the furnace is critical. Using a graphite furnace with a protective bed of a non-reactive material like Boron Nitride (BN) powder prevents the sample from oxidizing or reacting with the furnace elements.

Understanding the Trade-offs

Choosing the right sample preparation route involves balancing competing factors. There is no single "best" method for all situations.

Method vs. Material

The chosen milling and grinding techniques must be compatible with your sample. A very hard material requires a more aggressive milling method, but this increases the risk of contamination from the milling media itself.

Time vs. Quality

More advanced techniques like Cold Isostatic Pressing and two-step sintering produce higher-quality, more uniform samples. However, they are also more time-consuming and require specialized equipment compared to simpler dry pressing and single-step sintering.

Purity vs. Cost

Achieving high purity requires careful handling, high-purity raw materials, and controlled atmospheres, all of which increase costs. You must decide if the application's demands justify the added expense.

Making the Right Choice for Your Goal

Your final application dictates the necessary preparation steps. Tailor your process to the properties you need to achieve.

- If your primary focus is achieving maximum density: Prioritize fine particle milling, high-pressure compaction like CIP, and an optimized, high-temperature sintering cycle.

- If your primary focus is preserving chemical purity: Carefully select non-reactive milling media and ensure a clean, controlled sintering atmosphere.

- If your primary focus is creating complex shapes: You may need to incorporate binders during the powder stage and use die pressing to form the green body before sintering.

Mastering these preparation steps gives you direct control over the final properties and performance of your material.

Summary Table:

| Phase | Key Steps | Primary Goal |

|---|---|---|

| 1. Powder Creation | Milling/Grinding, Adding Solvents, Sieving | Achieve a uniform particle size and chemical composition. |

| 2. Powder Consolidation | Dry Pressing, Cold Isostatic Pressing (CIP) | Form a "green body" with high density and uniform shape. |

| 3. Thermal Treatment | Binder Burnout (Debinding), Sintering | Fuse particles into a strong, dense solid with controlled microstructure. |

Ready to achieve superior control over your sample's density, purity, and microstructure? The right equipment is critical for precise milling, pressing, and sintering. KINTEK specializes in high-quality lab equipment and consumables for all your sample preparation needs.

Contact our experts today to discuss how our solutions can help you optimize your process and get consistent, reliable results.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the physical properties of nitrogen gas? A Guide to Its Power and Invisible Dangers

- What is vacuum sputtering? A Guide to Precision Thin-Film Deposition

- What is a drying furnace? Choose the Right Heating Method for Your Material

- What is the thermal property of graphite? Mastering Extreme Heat Management

- Can you see mold with an infrared camera? How Thermal Imaging Reveals Hidden Moisture Problems

- What is the advantages of using biomass? Harness Renewable, Carbon-Neutral Energy

- What is the function of a laboratory filtration system in hydrothermal liquefaction? Maximize Biomass Yield

- What is the inert atmosphere in welding? Achieve Clean, Strong Welds with a Protective Gas Shield