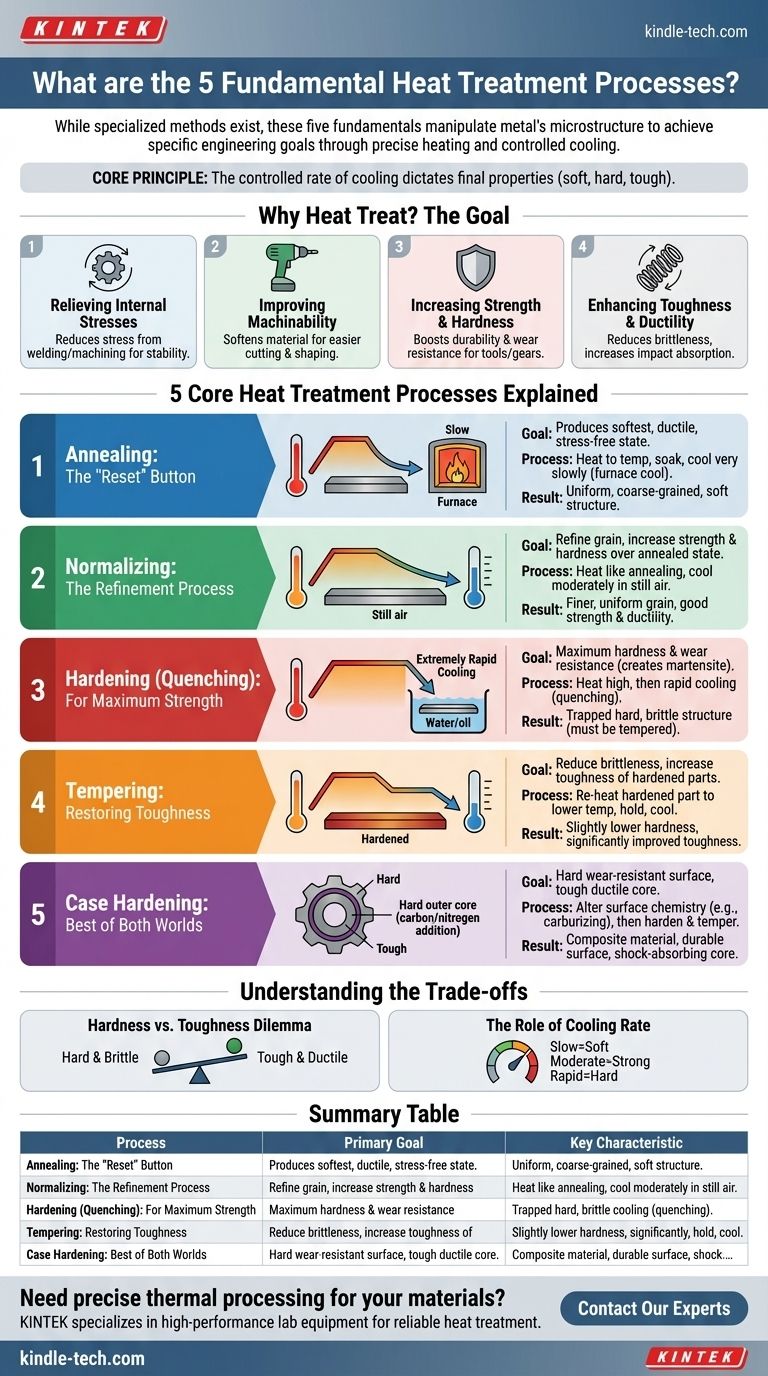

While there are many specialized methods, the five most fundamental heat treatment processes for metals are Annealing, Normalizing, Hardening (Quenching), Tempering, and Case Hardening. Each of these involves a precise cycle of heating and cooling designed to manipulate the internal microstructure of a material, altering its physical properties to achieve a specific engineering goal.

The core principle of heat treatment is not just about heating a metal, but about the controlled rate of cooling that follows. This cooling rate is the most critical variable that dictates whether the final material will be soft, hard, tough, or possess a combination of these properties.

The Goal of Heat Treatment: Why Do It?

Heat treatment is a foundational manufacturing process used to intentionally change a material's properties. It allows engineers to take a single type of metal, like steel, and customize its performance for a specific application.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or machining introduce significant internal stress. Heat treatment can relax this stress, making the part more stable and less prone to cracking or warping over time.

Improving Machinability

A material in its softest state is much easier to cut, drill, or shape. Certain heat treatments are performed specifically to prepare a material for subsequent machining operations, saving time and tool wear.

Increasing Strength and Hardness

For applications requiring high durability and wear resistance, such as gears or cutting tools, heat treatment is used to make the material significantly harder and stronger than it was in its raw state.

Enhancing Toughness and Ductility

Hardness often comes at the cost of brittleness. Other heat treatment processes are designed to reduce this brittleness, creating a material that is tough and can absorb impact without fracturing.

The 5 Core Heat Treatment Processes Explained

Each process follows a unique heating and cooling profile to achieve a different outcome.

1. Annealing: The "Reset" Button

- The Goal: To produce the softest, most ductile, and stress-free state possible for a metal. This is primarily done to make a material easier to machine or form.

- The Process: The metal is heated to a specific temperature, held there for a period of time (a "soak"), and then cooled very slowly, often by leaving it inside the furnace as it cools down.

- The Result: A material with a uniform, coarse-grained internal structure that is soft, easy to work with, and free of internal stresses.

2. Normalizing: The Refinement Process

- The Goal: To refine the grain structure and produce a material that is stronger and harder than an annealed one, but still has good ductility. It removes internal stresses caused by prior processing.

- The Process: The metal is heated to a temperature similar to annealing, but it is cooled moderately in still air outside the furnace.

- The Result: The faster cooling rate creates a finer, more uniform grain structure, which increases strength and hardness slightly compared to the fully annealed state.

3. Hardening (Quenching): For Maximum Strength

- The Goal: To make steel as hard and wear-resistant as possible.

- The Process: The steel is heated to a high temperature to transform its internal structure, then cooled extremely rapidly by plunging it into a liquid like water, oil, or brine. This is called quenching.

- The Result: The rapid cooling "traps" the steel in a very hard, brittle, and strong crystalline structure called martensite. The material is at its maximum hardness but is too brittle for most applications without further treatment.

4. Tempering: Restoring Toughness

- The Goal: To reduce the extreme brittleness of a hardened part and restore some of its toughness. Tempering is almost always performed immediately after hardening.

- The Process: The hardened part is re-heated to a much lower temperature (well below the hardening temperature), held for a specific time, and then cooled.

- The Result: This process relieves internal stresses and allows the brittle martensite structure to transform slightly, increasing the material's toughness and ductility. The trade-off is a slight reduction in hardness and strength.

5. Case Hardening (Surface Hardening): Best of Both Worlds

- The Goal: To create a part with an extremely hard, wear-resistant outer surface (the "case") while maintaining a softer, tougher, and more ductile interior (the "core").

- The Process: This involves a range of techniques (like carburizing or nitriding) where the chemical composition of the surface is altered, usually by adding carbon or nitrogen. After this, the part is typically hardened and tempered.

- The Result: A composite material perfect for components like gears, which need a very durable surface to resist wear but also a tough core to absorb shock and prevent shattering.

Understanding the Trade-offs

Choosing the right process requires understanding the fundamental relationship between key mechanical properties.

The Hardness vs. Toughness Dilemma

The most common trade-off in heat treatment is between hardness and toughness. A fully hardened (quenched) material is extremely hard but very brittle, like glass. Tempering it makes it less hard but significantly tougher, like a hammer. The higher the tempering temperature, the softer and tougher the part becomes.

The Role of Cooling Rate

The rate of cooling is the single most important factor.

- Very Slow Cooling (Annealing): Creates maximum softness.

- Moderate Cooling (Normalizing): Creates a refined, uniform structure with good strength.

- Rapid Cooling (Hardening): Creates maximum hardness and brittleness.

Matching the Process to Your Goal

- If your primary focus is maximum machinability: Use Annealing to make the material as soft and stress-free as possible before cutting.

- If your primary focus is a uniform structure after hot working: Use Normalizing to refine the grain structure and ensure predictable properties.

- If your primary focus is extreme wear resistance and strength: Use Hardening (Quenching), but always follow it with tempering.

- If your primary focus is durability and impact resistance: Use Tempering on a hardened part to reduce brittleness and increase toughness.

- If your primary focus is a wear-resistant surface with a shock-resistant core: Use Case Hardening for components like bearings and gears.

Ultimately, these processes are the tools an engineer uses to precisely define a metal's final performance characteristics for its intended job.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Annealing | Maximize softness & ductility | Very slow furnace cooling |

| Normalizing | Refine grain structure | Moderate air cooling |

| Hardening (Quenching) | Achieve maximum hardness | Rapid cooling (e.g., water, oil) |

| Tempering | Reduce brittleness, increase toughness | Low-temperature reheating after hardening |

| Case Hardening | Hard surface, tough core | Alters surface chemistry (e.g., carburizing) |

Need precise thermal processing for your materials?

The right heat treatment is critical for achieving the exact hardness, strength, and toughness your application demands. At KINTEK, we specialize in providing the high-performance lab equipment and consumables needed for reliable and repeatable heat treatment processes.

Whether you are in R&D or production, our solutions help you master Annealing, Hardening, Tempering, and more. Let's discuss how we can support your laboratory's specific needs—contact our experts today to get started!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are batch type furnaces? A Guide to Flexible, Controlled Thermal Processing

- Why does the selection of high-quality consumables impact SEM analysis? Unlock Precision for Austenitic Stainless Steels

- How is cannabis distillate extracted? A Step-by-Step Guide to Ultra-Pure THC & CBD

- How does a plasma incinerator work? Unlocking the Power of Plasma Gasification

- What are the two types of casting machines? Hot-Chamber vs. Cold-Chamber Die Casting

- What is a plasma furnace? Harness Ultra-High Temperatures for Extreme Material Processing

- What are the conditions for slow pyrolysis? Optimize for High-Quality Biochar Production

- What is the application of RF and DC sputtering? Choosing the Right Technique for Your Material