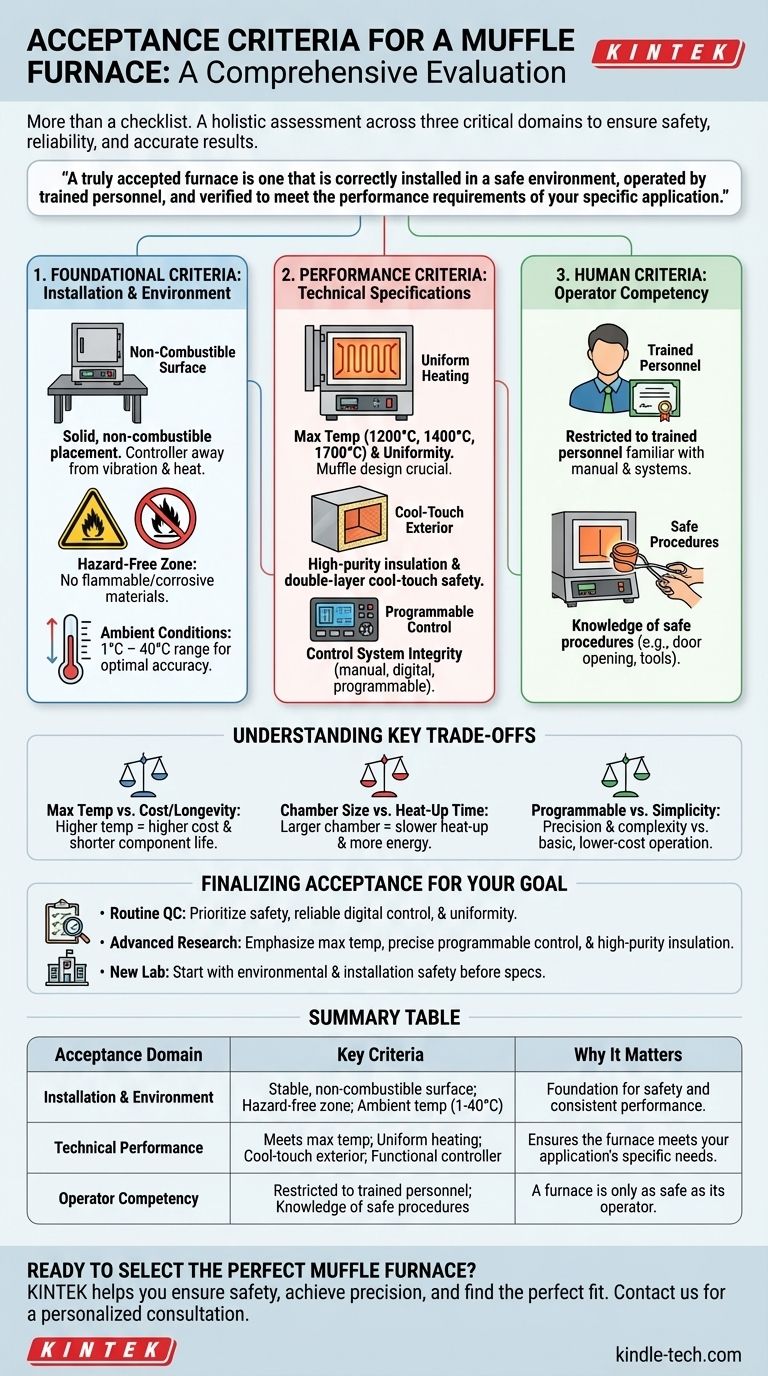

Acceptance criteria for a muffle furnace are not a single checklist, but a comprehensive evaluation across three critical domains: the installation environment, the operational readiness of personnel, and the technical performance specifications of the unit itself. Each area must meet specific standards to ensure safety, reliability, and accurate results.

The acceptance of a muffle furnace extends beyond its technical specifications. A truly accepted furnace is one that is correctly installed in a safe environment, operated by trained personnel, and verified to meet the performance requirements of your specific application.

Foundational Criteria: Installation and Environment

The physical location and ambient conditions are the first layer of acceptance. An improper environment can compromise both safety and furnace performance, regardless of the machine's quality.

Physical Stability and Placement

A muffle furnace must be placed on a solid, non-combustible surface, such as a concrete table or shelf. This prevents any risk of fire and ensures the unit remains stable during operation.

The controller unit must be positioned to avoid vibration and should not be too close to the furnace body. This prevents electronic components from failing due to excessive heat exposure.

Hazard-Free Zone

The working area must be completely free of flammable, explosive, and corrosive materials. High temperatures can cause volatile substances to ignite, and corrosive gases can rapidly degrade furnace components and electronics.

Ambient Operating Conditions

The furnace must operate within a specific ambient temperature range, typically between 1°C and 40°C. Operating outside these conditions can affect the controller's accuracy and the unit's ability to regulate temperature effectively.

Performance Criteria: Technical Specifications

Once the environment is confirmed as safe, you must verify that the furnace's technical capabilities align with your laboratory's needs. This is about matching the tool to the task.

Temperature Capability and Uniformity

The furnace must be able to reach and maintain its specified maximum temperature, which can be 1200°C, 1400°C, or 1700°C.

The core of the furnace is the muffle—a refractory-lined chamber that separates the heating elements from the sample. This design is critical for ensuring uniform heating and protecting your samples from direct radiation.

Insulation and External Safety

Modern furnaces use high-purity fibrous alumina insulation. This is a key acceptance point, as it directly impacts energy efficiency and heat-up times.

A critical safety feature is a double-layer steel structure with an air-cooling fan. This design ensures the external surface remains safe to touch, even at maximum internal temperature, which is a non-negotiable criterion for any modern lab.

Control System Integrity

The control system, whether manual, digital, or programmable, must function as specified. For programmable controllers, you must verify that they can execute heating and cooling profiles accurately and repeatably.

Human Criteria: Operator Competency

A furnace is only as safe as the person using it. Acceptance must include verification that operators are properly prepared.

Required Training

Operation must be restricted to trained personnel. An operator is not considered qualified until they are thoroughly familiar with the instruction manual and all supporting electrical and safety systems.

Understanding of Safe Procedures

Operators must demonstrate knowledge of correct procedures, such as opening the furnace door before placing or removing samples and using appropriate tools to handle hot crucibles to prevent severe burns.

Understanding the Key Trade-offs

Accepting a furnace involves balancing its features. No single furnace is perfect for every task, and you must understand the inherent compromises.

Maximum Temperature vs. Cost and Longevity

Furnaces capable of higher temperatures (e.g., 1700°C) require more advanced and expensive materials for heating elements and insulation. These components may also have a shorter operational lifespan, leading to higher maintenance costs.

Chamber Size vs. Heat-Up Time

A larger chamber offers more capacity but requires more energy and time to reach the target temperature. Smaller chambers are faster and often more energy-efficient but limit the size and quantity of samples you can process at once.

Programmable Control vs. Simplicity

A fully programmable controller provides exceptional precision and repeatability for complex thermal cycling. However, it adds complexity and a higher initial cost compared to a simpler digital or manual controller, which may be perfectly adequate for basic ashing or heat-treating tasks.

Finalizing Acceptance for Your Goal

Use these criteria to make a definitive decision based on your specific requirements.

- If your primary focus is routine quality control: Prioritize a furnace with robust safety features (cool-touch exterior), a reliable digital controller, and proven temperature uniformity.

- If your primary focus is advanced materials research: Emphasize maximum temperature capability, a precise programmable controller for complex profiles, and high-purity insulation.

- If your primary focus is establishing a new lab: Begin by ensuring all environmental and installation criteria are met to create a safe foundation before evaluating the performance specifications of any furnace.

A systematic evaluation of the furnace, its environment, and its operator is the only way to guarantee safe and successful outcomes.

Summary Table:

| Acceptance Domain | Key Criteria | Why It Matters |

|---|---|---|

| Installation & Environment | Stable, non-combustible surface; Hazard-free zone; Ambient temp (1-40°C) | Foundation for safety and consistent performance. |

| Technical Performance | Meets max temp (e.g., 1200°C, 1700°C); Uniform heating; Cool-touch exterior; Functional controller | Ensures the furnace meets your application's specific needs. |

| Operator Competency | Restricted to trained personnel; Knowledge of safe procedures | A furnace is only as safe as its operator. |

Ready to Select the Perfect Muffle Furnace for Your Lab?

Choosing the right equipment is critical for the safety and success of your laboratory operations. KINTEK specializes in high-quality lab equipment and consumables, providing reliable muffle furnaces designed to meet rigorous acceptance criteria.

We help you:

- Ensure Safety: Our furnaces feature robust safety designs like cool-touch exteriors.

- Achieve Precision: Benefit from excellent temperature uniformity and control for accurate results.

- Find the Perfect Fit: Get expert guidance to select a furnace that matches your specific application, whether it's for quality control or advanced research.

Let's discuss your lab's needs. Contact KINTEK today for a personalized consultation and ensure your next muffle furnace is a perfect, safe fit for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the minimum temperature for a muffle furnace? Understanding Its High-Tech Design

- What is the structure of a muffle furnace? A Guide to Its Core Components and Design

- What is the difference between a muffle furnace and a drying oven? Choose the Right Thermal Tool

- What is the difference between muffle furnace and hot air oven? Choose the Right Heating Tool for Your Lab

- What is the use of muffle furnace in food lab? Essential for Accurate Ash Content Analysis