At its core, annealing is a heat treatment process that fundamentally alters a material's microstructure to make it more workable. The primary advantages are increased ductility, relieved internal stresses, and improved machinability. This process effectively "resets" the material, making it softer and less brittle after it has been hardened by processes like casting or cold working.

Annealing should be viewed as a strategic trade-off. You are intentionally reducing a material's hardness and strength in exchange for significant gains in ductility and internal stability, enabling further manufacturing processes that would otherwise be impossible.

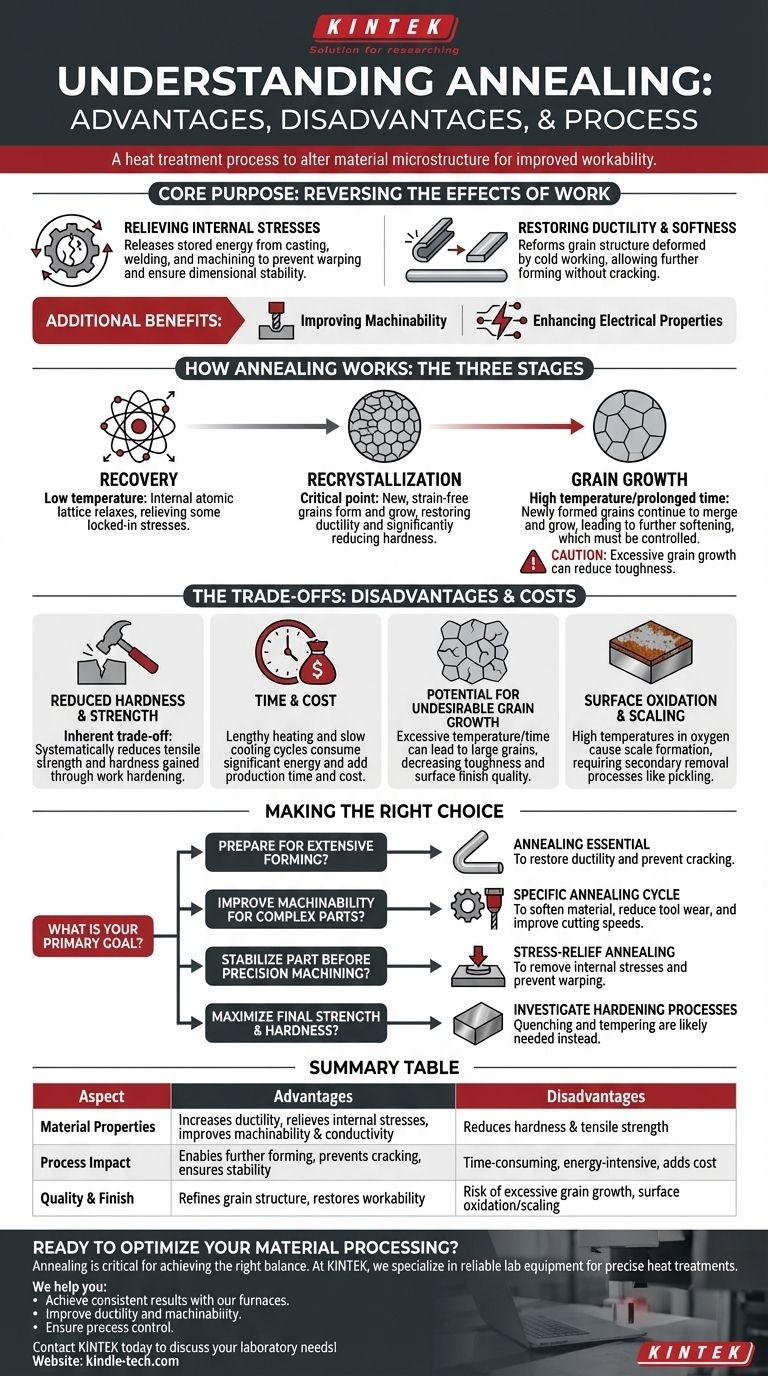

The Core Purpose: Reversing the Effects of Work

Annealing is not one process but a family of treatments designed to reverse the effects of strain hardening and relieve internal stresses locked within a material's structure.

Relieving Internal Stresses

Processes like casting, welding, and aggressive machining introduce significant internal stresses into a material.

These hidden stresses can cause a part to warp or distort over time or during subsequent heat treatments. Annealing provides a controlled way to release this stored energy, ensuring dimensional stability.

Restoring Ductility and Softness

When a metal is bent, stamped, or drawn (a process known as cold working), its internal grain structure becomes deformed and strained, making it harder but also more brittle.

Annealing reverses this by allowing the microstructure to reform. This restoration of ductility is critical, as it allows for additional forming operations without the risk of the material cracking.

Improving Machinability

Hard, brittle materials are difficult to machine. They cause rapid tool wear and can result in a poor surface finish.

By softening the material, annealing significantly improves its machinability. Cutting tools can remove material more easily and efficiently, leading to lower costs and higher quality parts.

Enhancing Electrical Properties

For certain materials, particularly copper, the internal defects and stresses from cold working can impede the flow of electrons.

Annealing can refine the grain structure and reduce these defects, thereby improving the material's electrical conductivity.

How Annealing Works: The Three Stages

The transformation during annealing occurs in three distinct, temperature-dependent stages that restructure the material at a microscopic level.

Stage 1: Recovery

As the material is heated, the first stage to occur is Recovery. At this relatively low temperature, the material's internal atomic lattice begins to relax, relieving some of the locked-in stresses from cold working.

Stage 2: Recrystallization

As the temperature increases to a critical point, the Recrystallization stage begins. New, strain-free grains start to form and grow, completely replacing the old, deformed grains created during cold working.

This stage is the heart of the annealing process. It is where the material's original ductility is restored and its hardness is significantly reduced.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long, the newly formed, strain-free grains will continue to merge and grow larger.

This Grain Growth can further soften the material, but it must be carefully controlled. Excessive grain growth can sometimes be detrimental to other mechanical properties, like toughness.

Understanding the Trade-offs and Disadvantages

While highly beneficial, annealing is not without its costs and potential downsides. It is a deliberate compromise chosen for a specific manufacturing outcome.

Reduced Hardness and Strength

The most significant disadvantage is inherent to its purpose: annealing makes a material softer. It systematically reduces the tensile strength and hardness that may have been gained through work hardening. This is a direct and unavoidable trade-off for increased ductility.

Time and Cost

Annealing is not an instantaneous process. It requires slowly heating a material in a furnace, holding it at a specific temperature (soaking), and then slowly cooling it.

This cycle can take many hours and consumes a significant amount of energy, adding both time and cost to the overall production process.

Potential for Undesirable Grain Growth

If the annealing temperature is too high or the soaking time is too long, the result can be excessive grain growth. Overly large grains can decrease the material's toughness and lead to a poor surface finish after subsequent forming operations.

Surface Oxidation and Scaling

Heating metals to high temperatures in the presence of oxygen will cause a layer of oxide, or scale, to form on the surface. This scale is often undesirable and must be removed through secondary processes like pickling or grinding, adding another step and cost to manufacturing.

Making the Right Choice for Your Goal

Selecting annealing depends entirely on the material's current state and the next step in your manufacturing sequence.

- If your primary focus is preparing for extensive forming or drawing: Annealing is essential to restore ductility and prevent the material from cracking during the operation.

- If your primary focus is improving machinability for complex parts: A specific annealing cycle can soften the material just enough to reduce tool wear and improve cutting speeds.

- If your primary focus is stabilizing a part before final, high-precision machining: Stress-relief annealing is critical to remove internal stresses that would otherwise cause the part to warp after material is removed.

- If your primary focus is maximizing final strength and hardness: Annealing is the opposite of what you need; you should investigate hardening processes like quenching and tempering instead.

Ultimately, annealing is a powerful tool for manipulating a material's properties to achieve a specific engineering goal.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Material Properties | Increases ductility, relieves internal stresses, improves machinability and electrical conductivity | Reduces hardness and tensile strength |

| Process Impact | Enables further forming operations, prevents cracking, ensures dimensional stability | Time-consuming, energy-intensive, adds cost |

| Quality & Finish | Refines grain structure, restores workability | Risk of excessive grain growth, surface oxidation/scaling |

Ready to optimize your material processing with precise heat treatment?

Annealing is a critical step for achieving the right balance of material properties in your lab or production line. At KINTEK, we specialize in providing the reliable lab equipment you need to perform annealing and other heat treatments with precision and repeatability.

We help you:

- Achieve consistent results with our range of laboratory furnaces.

- Improve your material's ductility and machinability for better manufacturing outcomes.

- Ensure process control to avoid disadvantages like excessive grain growth.

Let our experts help you select the perfect equipment for your specific materials and goals. Contact KINTEK today to discuss your laboratory needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is oxidation in brazing? How to prevent it for strong, durable joints

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond