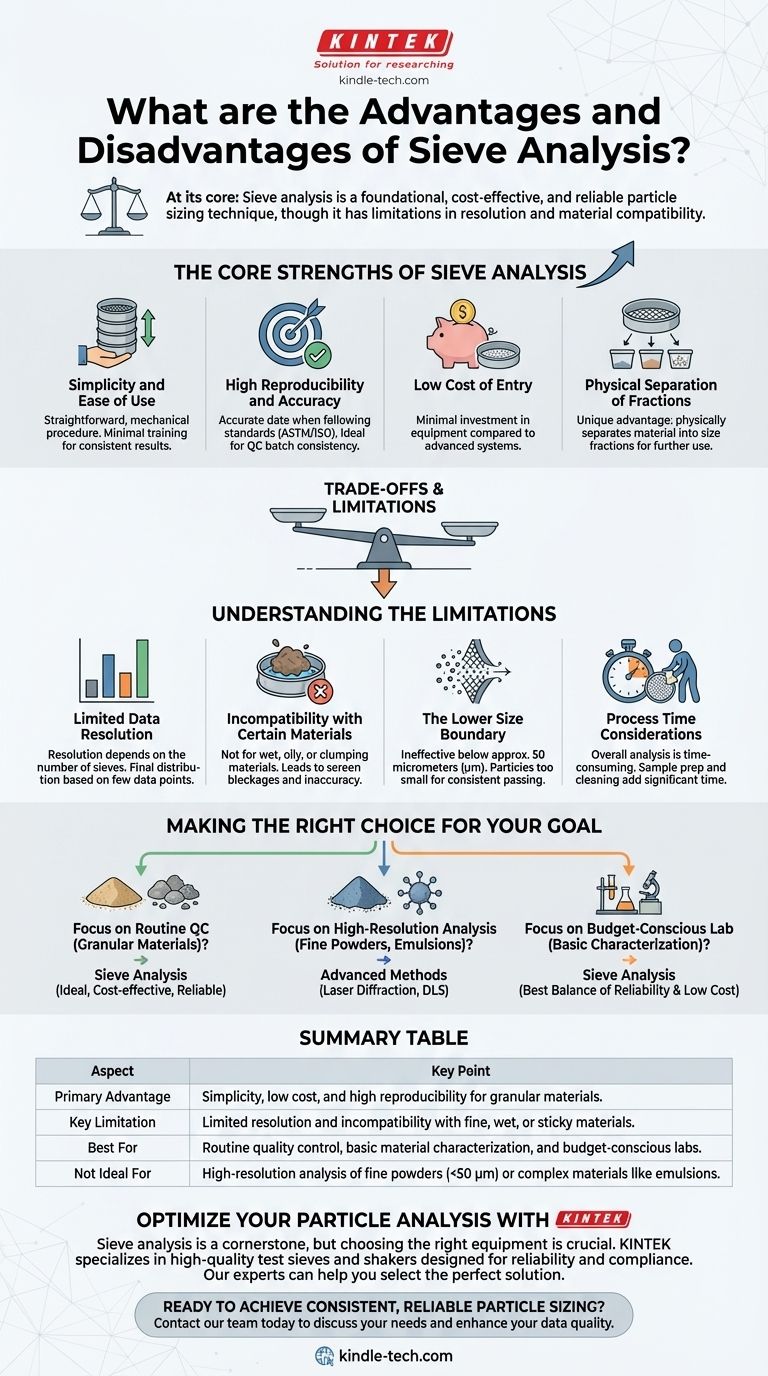

At its core, sieve analysis is a foundational technique in particle size analysis celebrated for its simplicity, low cost, and reliability. Its primary advantages are its ease of use and the highly reproducible results it delivers, while its main disadvantages stem from its limited resolution and its incompatibility with very fine or non-dry materials.

Sieve analysis remains an indispensable tool for fundamental quality control and material characterization. The central trade-off is choosing its cost-effective simplicity versus the higher resolution and broader material compatibility offered by more advanced, and more expensive, analytical methods.

The Core Strengths of Sieve Analysis

Sieve analysis is a trusted method for good reason. Its advantages make it the go-to choice for countless applications where a fundamental understanding of particle size distribution is sufficient.

Simplicity and Ease of Use

The procedure is straightforward and mechanical. It involves stacking sieves of decreasing mesh size, placing a sample on top, and agitating the stack until the particles have settled into their respective size fractions.

This simplicity means minimal training is required for operators to achieve consistent results.

High Reproducibility and Accuracy

When performed according to established standards (like ASTM or ISO), sieve analysis provides remarkably accurate and reproducible data.

This reliability makes it an excellent tool for quality control, where the goal is to ensure batch-to-batch consistency against a known standard.

Low Cost of Entry

The initial investment for a set of certified test sieves and a sieve shaker is minimal compared to laser diffraction or image analysis systems.

This makes it accessible for a wide range of labs, from educational settings to industrial quality control departments.

Physical Separation of Fractions

A unique advantage is that sieve analysis physically separates the material into different size fractions.

These separated fractions can then be used for further testing or analysis, which is not possible with many other particle sizing methods.

Understanding the Trade-offs and Limitations

While powerful, the method's simplicity comes with clear limitations that make it unsuitable for certain materials or analytical goals. Understanding these trade-offs is critical to its proper application.

Limited Data Resolution

The resolution of your data is directly tied to the number of sieves in your stack. A standard stack may have up to eight sieves.

This means your final particle size distribution curve is based on just eight data points, which can miss finer details within the distribution.

Incompatibility with Certain Materials

Sieve analysis is fundamentally a dry process. The method is not suitable for materials that are wet, oily, or that clump together when agitated.

Attempting to sieve these materials will lead to screen blockages (blinding) and inaccurate results.

The Lower Size Boundary

There is a practical lower limit to the particle size that can be reliably measured.

Generally, woven wire mesh sieves are not effective below approximately 50 micrometers (µm), as the particles become too small to pass through the openings consistently.

Process Time Considerations

While the mechanical shaking process can be short, the overall analysis can be time-consuming.

Sample preparation, which often includes drying, weighing, careful collection of material from each sieve, and cleaning, adds significant time to the total procedure.

Making the Right Choice for Your Goal

Selecting the right particle analysis method depends entirely on your material, your budget, and the specific data you need.

- If your primary focus is routine quality control for granular materials (like sand, aggregates, or grains): Sieve analysis is the ideal, cost-effective, and highly reliable choice.

- If your primary focus is high-resolution analysis of fine powders, nanoparticles, or emulsions: You must use a more advanced method like laser diffraction or dynamic light scattering.

- If your primary focus is a budget-conscious lab setup for basic material characterization: Sieve analysis provides the best balance of reliable data and low initial investment.

Ultimately, sieve analysis serves as a robust and essential workhorse for foundational particle sizing.

Summary Table:

| Aspect | Key Point |

|---|---|

| Primary Advantage | Simplicity, low cost, and high reproducibility for granular materials. |

| Key Limitation | Limited resolution and incompatibility with fine, wet, or sticky materials. |

| Best For | Routine quality control, basic material characterization, and budget-conscious labs. |

| Not Ideal For | High-resolution analysis of fine powders (<50 µm) or complex materials like emulsions. |

Optimize Your Particle Analysis with KINTEK

Sieve analysis is a cornerstone of quality control, but choosing the right equipment is crucial for accurate, reproducible results. KINTEK specializes in high-quality lab equipment, including robust test sieves and efficient sieve shakers designed for reliability and compliance with industry standards.

Whether you're setting up a new lab or upgrading your particle analysis capabilities, our experts can help you select the perfect solution for your specific materials and applications.

Ready to achieve consistent, reliable particle sizing? Contact our team today to discuss your needs and discover how KINTEK's laboratory solutions can enhance your efficiency and data quality.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- What are advantages and disadvantages of sieving method? A Guide to Reliable & Cost-Effective Particle Sizing

- Which equipment is operated for sieves when perform sieving tests? Achieve Accurate Particle Size Analysis

- What are the apparatus used for sieve analysis? Build a Reliable Particle Sizing System

- How long do I run my sieve shaker for? Find Your Material's Optimal Sieving Time