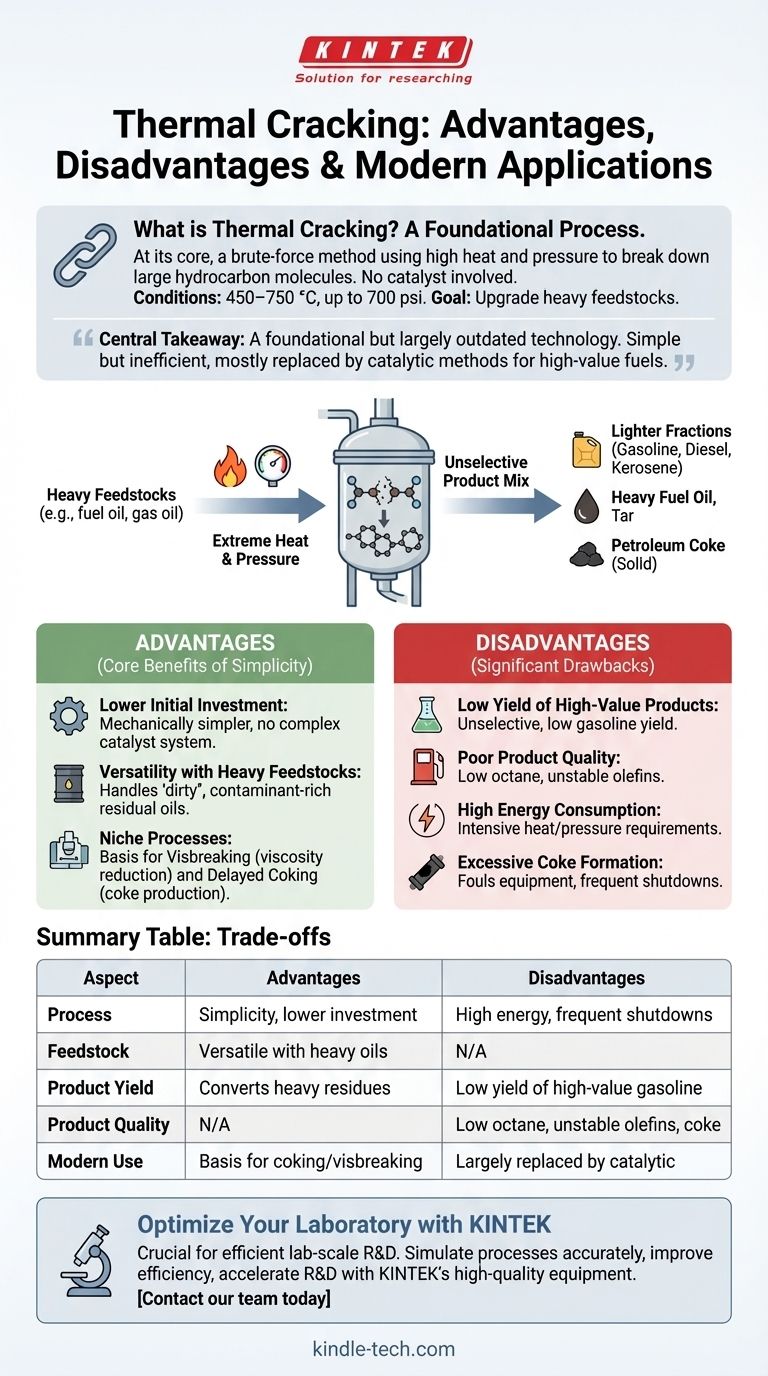

At its core, thermal cracking is a brute-force method that uses high heat and pressure to break down large hydrocarbon molecules. Its main advantages are its simplicity and ability to process very heavy, low-value feedstocks, while its primary disadvantages are poor product quality, low yields of valuable products like gasoline, and high energy consumption.

The central takeaway is that thermal cracking is a foundational but largely outdated technology for gasoline production. While its simplicity is an advantage, its inefficiency and the low quality of its output mean it has been almost entirely replaced by more advanced catalytic methods for producing high-value fuels.

What is Thermal Cracking? A Foundational Process

Thermal cracking was one of the earliest methods developed to increase the production of gasoline from crude oil. It operates on a straightforward principle: applying extreme conditions to force chemical bonds to break.

The Core Mechanism: Heat and Pressure

The process involves heating heavy hydrocarbon fractions, like fuel oil or gas oil, to very high temperatures (450–750 °C) under significant pressure (up to 700 psi). These severe conditions provide the energy needed to spontaneously sever the carbon-carbon bonds in large molecules, breaking them into smaller, lighter ones. No catalyst is involved.

The Primary Goal: Upgrading Heavy Feedstocks

The fundamental goal is economic: to convert heavy, low-value hydrocarbon streams into lighter, more valuable products. This includes turning materials from the "bottom of the barrel" into components for gasoline, diesel, and kerosene.

The Products: An Unselective Mix

Because the process is non-selective, it creates a wide array of products. This includes the desired lighter fractions but also significant amounts of heavy fuel oil, tar, and solid petroleum coke. The gasoline produced is rich in unstable olefins and has a very low octane rating.

The Core Advantages of Simplicity

While largely superseded, the simplicity of thermal cracking provides a few key benefits that keep variants of the process relevant in specific niches.

Lower Initial Investment

Compared to modern catalytic units, a thermal cracker is mechanically simpler. It does not require a complex and costly reactor-regenerator system for handling a catalyst, which can lower the initial capital expenditure.

Versatility with Heavy Feedstocks

Thermal processes excel at handling very heavy, contaminant-rich residual oils. These "dirty" feedstocks would quickly deactivate or "poison" the sensitive catalysts used in methods like Fluid Catalytic Cracking (FCC), making thermal cracking a viable first-pass upgrading step.

Niche Processes like Coking and Visbreaking

The principles of thermal cracking are the basis for important modern processes. Visbreaking is a mild form used to reduce the viscosity of heavy fuel oil, making it easier to transport. Delayed coking is a severe form designed specifically to maximize the production of petroleum coke, a valuable solid product used in creating electrodes.

Understanding the Significant Disadvantages

The drawbacks of thermal cracking are substantial and are the primary reason it is no longer the preferred method for producing transportation fuels.

Low Yield of High-Value Products

The "brute force" nature of thermal cracking is not precise. It produces a relatively low yield of gasoline compared to catalytic methods, with a larger portion of the feedstock ending up as less valuable heavy oils and coke.

Poor Product Quality

The gasoline produced via thermal cracking has a very low octane number, making it unsuitable for modern high-compression engines without significant further processing. The high concentration of unstable olefins also means the products can form gums and deposits over time.

High Energy Consumption

Maintaining the extreme temperatures and pressures required for the reactions is incredibly energy-intensive. This results in high operating costs and a significant environmental footprint compared to the lower-temperature catalytic processes.

Excessive Coke Formation

A common and problematic byproduct is coke, a hard, carbon-rich solid. Coke deposits rapidly foul the inside of reactor coils and equipment, forcing frequent shutdowns for difficult and time-consuming cleaning procedures.

How to Apply This to Your Goal

Understanding these trade-offs is key to recognizing where thermal processes fit within the modern refinery landscape.

- If your primary focus is upgrading the heaviest residues: Thermal processes like coking and visbreaking are the industry-standard tools for processing the "bottom of the barrel" into more valuable streams.

- If your primary focus is maximizing high-octane gasoline: Thermal cracking is the wrong choice; Fluid Catalytic Cracking (FCC) is far more efficient and produces a superior quality product for this purpose.

- If your primary focus is a low-cost entry for basic upgrading: A simple thermal unit might be considered, but its high operating costs and low-value output make it economically challenging in most markets.

Ultimately, thermal cracking represents the essential first step in refining technology, a foundation upon which more efficient and precise catalytic processes were built.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Process | Simplicity, lower initial investment | High energy consumption, frequent shutdowns |

| Feedstock | Versatile with heavy, contaminant-rich oils | N/A |

| Product Yield | Converts heavy residues to lighter streams | Low yield of high-value gasoline |

| Product Quality | N/A | Low octane rating, unstable olefins, coke formation |

| Modern Use | Basis for coking and visbreaking processes | Largely replaced by catalytic cracking for fuels |

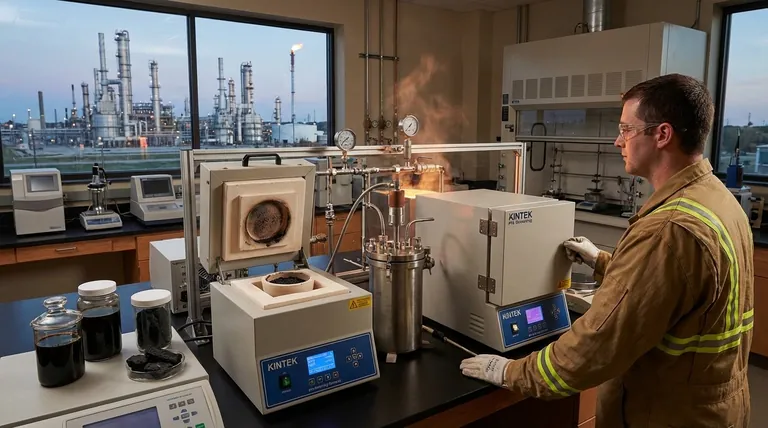

Optimize Your Laboratory's Hydrocarbon Processing with KINTEK

Understanding the trade-offs of industrial processes like thermal cracking is crucial for efficient lab-scale research and development. Whether you are analyzing heavy feedstocks, developing new catalytic methods, or simulating refining conditions, having the right equipment is key.

KINTEK specializes in providing high-quality lab equipment and consumables tailored to the needs of energy and chemical research laboratories. We can help you:

- Simulate Processes Accurately: From basic thermal reactors to advanced catalytic systems.

- Improve Efficiency: With precise temperature control and durable equipment designed for demanding conditions.

- Accelerate R&D: By supplying reliable tools that reduce downtime and enhance experimental repeatability.

Let our expertise support your work in advancing fuel technology. Contact our team today to discuss how KINTEK's solutions can meet your specific laboratory challenges and drive your research forward.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is an electric muffle furnace? Achieve Unmatched Thermal Purity and Uniformity

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs