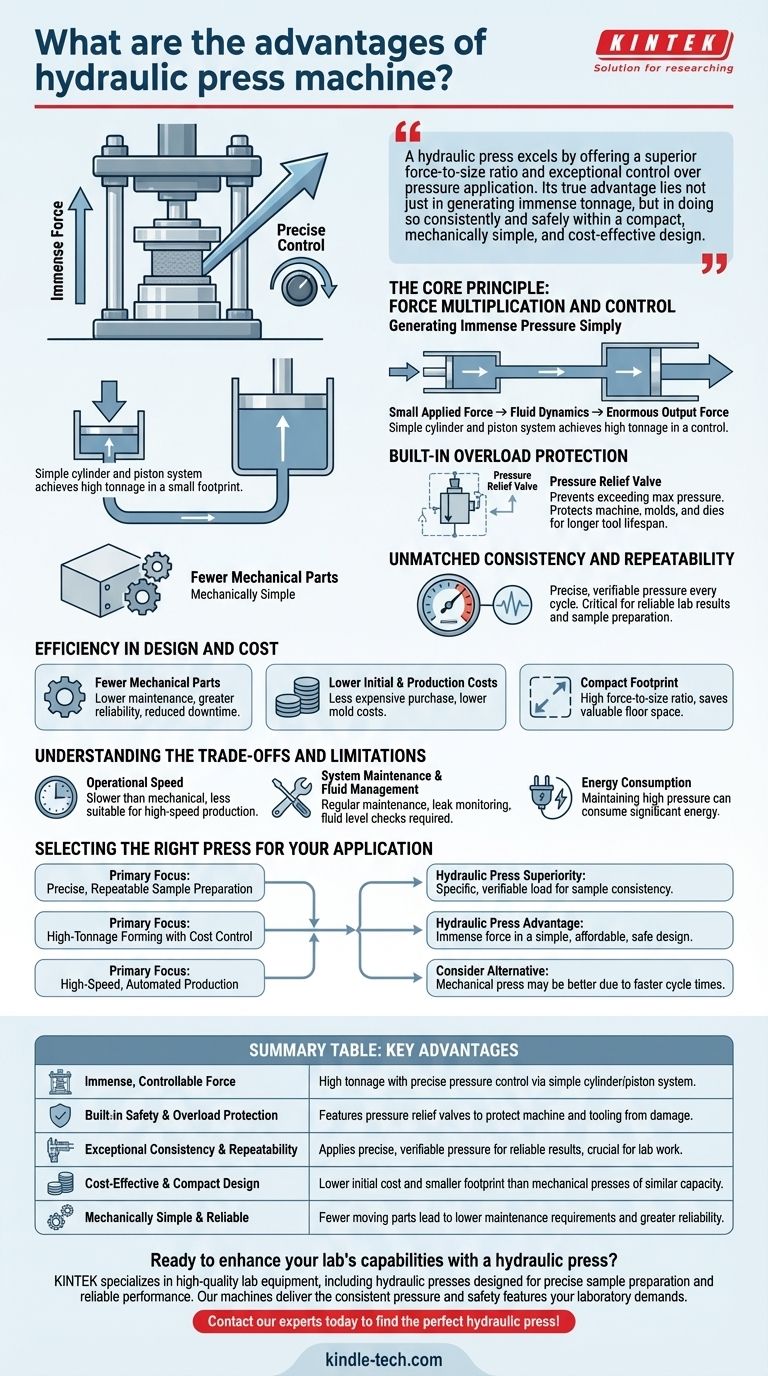

The primary advantages of a hydraulic press stem from its ability to generate immense, controllable force using a simple and robust design. This results in a machine that is not only cost-effective and compact but also offers superior safety features like built-in overload protection, quieter operation, and exceptional consistency in pressure application.

A hydraulic press excels by offering a superior force-to-size ratio and exceptional control over pressure application. Its true advantage lies not just in generating immense tonnage, but in doing so consistently and safely within a compact, mechanically simple, and cost-effective design.

The Core Principle: Force Multiplication and Control

The fundamental benefits of a hydraulic press are a direct result of how it uses fluid dynamics to multiply force. This core principle underpins its most significant advantages in industrial and laboratory settings.

Generating Immense Pressure Simply

A hydraulic press uses a simple cylinder and piston system to translate a small applied force into an enormous output force. This principle allows it to achieve incredibly high tonnage within a relatively small physical footprint.

This design is mechanically simple, with fewer moving parts compared to complex geared or lever-based mechanical presses.

Built-in Overload Protection

Every hydraulic system has a pressure relief valve. This valve acts as a natural safety mechanism, preventing the press from exceeding its maximum rated pressure.

This protects not only the machine itself from damage but also the expensive molds and dies being used, contributing to a longer tool lifespan.

Unmatched Consistency and Repeatability

Hydraulic presses, particularly modern versions, can apply a precise and consistent amount of pressure with every cycle. Many include a pressure gauge, allowing for verifiable and repeatable operations.

This is critical in applications like laboratory sample preparation, where inconsistent pressure can lead to unreliable test results and wasted materials.

Efficiency in Design and Cost

The simplicity of the hydraulic press translates directly into economic and operational efficiencies that make it a highly adaptable tool.

Fewer Mechanical Parts

The straightforward design reduces the number of components that can wear out or fail. This results in greater reliability, lower maintenance requirements, and reduced operational downtime.

Lower Initial and Production Costs

Compared to mechanical presses of similar tonnage, hydraulic presses are often less expensive to purchase. Their simple design can also lead to lower costs for the molds and tooling used with them.

Compact Footprint

Because they can generate so much force relative to their size, hydraulic presses require less floor space than mechanical alternatives capable of the same output. This is a significant advantage in crowded workshops or labs.

Understanding the Trade-offs and Limitations

To make an informed decision, it's crucial to recognize where a hydraulic press may not be the optimal choice. Its unique strengths come with inherent trade-offs.

Operational Speed

Hydraulic presses are generally slower than their mechanical counterparts. The time it takes to build and release fluid pressure makes them less suitable for high-speed, high-volume production lines where cycle time is the primary concern.

System Maintenance and Fluid Management

While mechanically simple, the hydraulic system itself requires regular maintenance. This includes monitoring for fluid leaks, checking fluid levels and quality, and ensuring hoses and seals are in good condition.

Additionally, some hydraulic fluids can be flammable, requiring specific safety protocols.

Energy Consumption

Maintaining high pressure throughout a long pressing cycle can consume a significant amount of energy, which can be a factor in long-term operational costs.

Selecting the Right Press for Your Application

Choosing the correct equipment depends entirely on your primary goal. A hydraulic press is an exceptional tool when its strengths align with the specific demands of the task.

- If your primary focus is precise, repeatable sample preparation: The hydraulic press is superior due to its ability to apply a specific, verifiable load every time, ensuring sample consistency.

- If your primary focus is high-tonnage forming with cost control: The hydraulic press offers an unmatched ability to deliver immense force in a simple, affordable, and safe design.

- If your primary focus is high-speed, automated production: The slower cycle time of a hydraulic press may be a significant drawback, and a mechanical press is likely a better alternative.

Ultimately, a hydraulic press provides a unique blend of power, precision, and simplicity, making it an invaluable tool for applications where controlled force is paramount.

Summary Table:

| Key Advantage | Description |

|---|---|

| Immense, Controllable Force | Generates high tonnage with precise pressure control via a simple cylinder/piston system. |

| Built-in Safety & Overload Protection | Features pressure relief valves to protect the machine and tooling from damage. |

| Exceptional Consistency & Repeatability | Applies precise, verifiable pressure for reliable results, crucial for lab work. |

| Cost-Effective & Compact Design | Lower initial cost and smaller footprint than mechanical presses of similar capacity. |

| Mechanically Simple & Reliable | Fewer moving parts lead to lower maintenance requirements and greater reliability. |

Ready to enhance your lab's capabilities with a hydraulic press?

KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for precise sample preparation and reliable performance. Our machines deliver the consistent pressure and safety features your laboratory demands.

Contact our experts today to find the perfect hydraulic press for your specific application and experience the KINTEK difference in quality and support!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How is a laboratory hydraulic press used in preparing Fe-Cr-Al sintered samples for XRD? Expert Guide

- What causes hydraulics to run slow? Diagnose Flow Issues for Faster Operation

- What is a socket press used for? Achieve Professional Fastener Installation Every Time

- Why KBr is used as material for pellets formation in IR-spectroscopy? The Ideal Matrix for Clear, Accurate Analysis

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- How much weight can a hydraulic press? The Real Measure is Tonnage, Not Machine Weight

- What is a wood pellet mill? Turn Waste Biomass into High-Density Fuel

- How does a laboratory hydraulic press facilitate the sample preparation for cellulose citrate? Optimize IR Accuracy