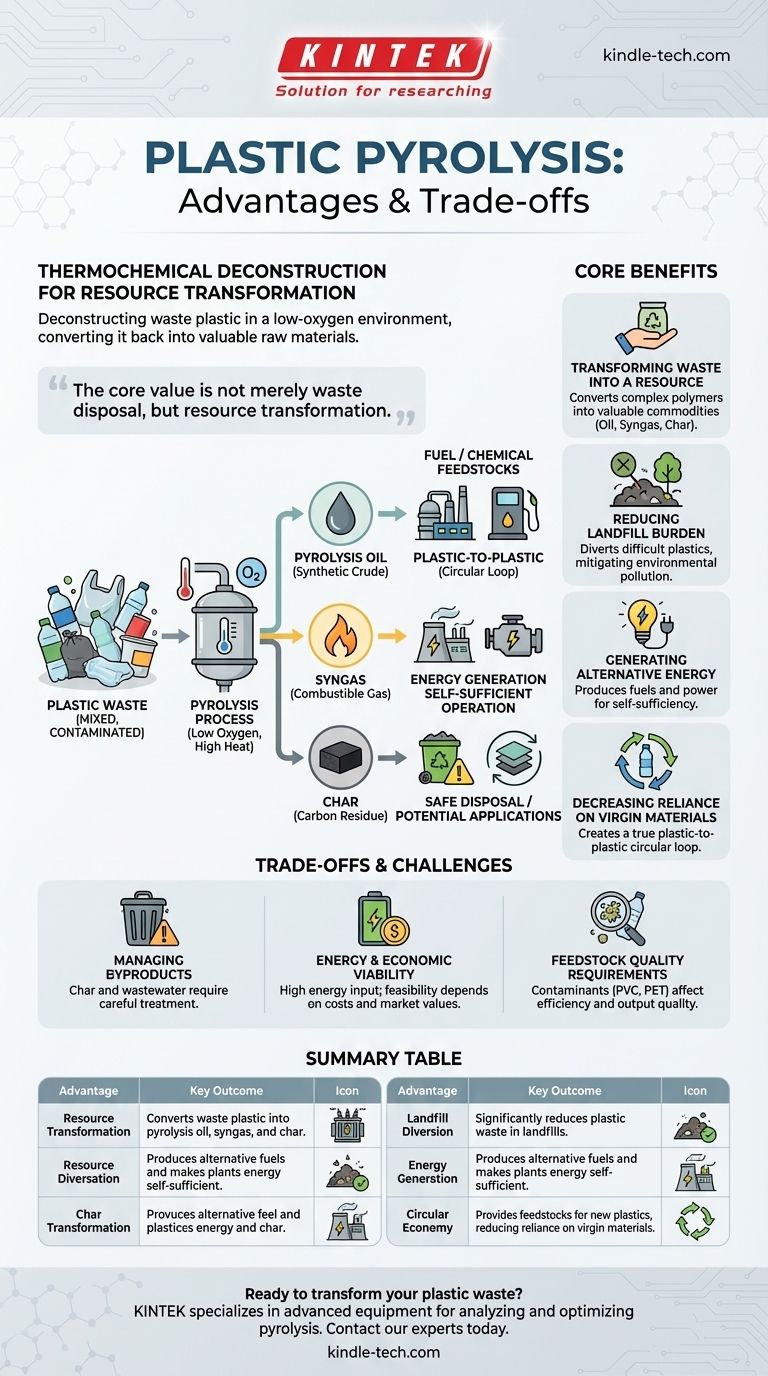

In essence, plastic pyrolysis is a thermochemical process that deconstructs waste plastic in a low-oxygen environment, converting it back into valuable raw materials. Its primary advantages are the significant reduction of landfill waste, the creation of alternative energy sources and chemical feedstocks, and the promotion of a more circular economy by recovering value from what would otherwise be discarded.

The core value of plastic pyrolysis is not merely waste disposal, but resource transformation. It reclaims the locked-in energy and chemical value from end-of-life plastics, converting a persistent environmental problem into a source for new fuels and materials.

The Core Benefits of Plastic Pyrolysis

The process addresses several critical environmental and economic challenges simultaneously by fundamentally changing the "end-of-life" equation for many types of plastic.

Transforming Waste into a Resource

Plastic pyrolysis converts complex polymer chains into simpler, valuable outputs. The main products are pyrolysis oil (a synthetic crude oil), syngas (a combustible gas), and char (a solid carbon residue).

These outputs are not waste; they are commodities. This conversion effectively turns a low-value, high-volume waste stream into a source of marketable products.

Reducing Landfill Burden and Pollution

Massive quantities of plastic waste, particularly mixed or contaminated plastics that are difficult to mechanically recycle, end up in landfills or polluting natural ecosystems.

Pyrolysis provides a robust solution for these challenging plastic streams. By diverting this waste from landfills, it directly mitigates land use, soil contamination, and the release of plastics into the environment.

Generating Alternative Energy Sources

The outputs of pyrolysis have significant energy value. The pyrolysis oil can be refined into fuels comparable to diesel or used as a heating oil.

The syngas produced during the process has a high calorific value and is typically used to power the pyrolysis plant itself, making the operation more energy self-sufficient. Any excess can be used for electricity generation.

Decreasing Reliance on Virgin Materials

The oil and gas from pyrolysis are valuable chemical feedstocks. Instead of being burned for energy, the pyrolysis oil can be "upgraded" and used in steam crackers to produce new, virgin-quality plastics.

This creates a true "plastic-to-plastic" circular loop, reducing the demand for the fossil fuels that are the conventional source for manufacturing new plastics.

Understanding the Trade-offs and Challenges

While the advantages are significant, a balanced assessment requires acknowledging the technical and operational realities of the process.

Managing the Byproducts

Pyrolysis is not a zero-waste process. It produces a solid carbon residue, or char, which can contain heavy metals and other contaminants from the original plastic feedstock. This char requires careful management, either through safe disposal or by finding applications where its contaminants are not a risk.

Additionally, any moisture in the plastic waste is converted to wastewater, which must be treated before being discharged.

Energy and Economic Viability

Pyrolysis is an endothermic process, meaning it requires a significant input of energy to maintain the high temperatures needed to break down the plastics.

While the process can be made partially self-sustaining by using its own syngas as fuel, the overall economic feasibility is sensitive to factors like feedstock cost, energy prices, and the market value of the output oil.

Feedstock Quality Requirements

The efficiency of the process and the quality of the output oil are highly dependent on the type and cleanliness of the plastic feedstock.

Contaminants like PVC, PET, food waste, or dirt can lower the quality of the oil and create corrosive compounds (like hydrochloric acid from PVC) that complicate plant operation and maintenance.

Making the Right Choice for Your Goal

Evaluating pyrolysis requires aligning its capabilities with your specific objective.

- If your primary focus is waste volume reduction: Pyrolysis is a powerful tool for diverting large quantities of mixed and otherwise non-recyclable plastics from landfills.

- If your primary focus is energy independence: The process offers a decentralized method to convert local plastic waste into usable liquid fuels and electricity.

- If your primary focus is advancing a circular economy: Pyrolysis is one of the few technologies that can break down polymers into basic chemical feedstocks, enabling the production of new plastics from waste.

By understanding its distinct advantages and inherent challenges, you can accurately position plastic pyrolysis as a strategic component of a modern, sustainable resource management system.

Summary Table:

| Advantage | Key Outcome |

|---|---|

| Resource Transformation | Converts waste plastic into pyrolysis oil, syngas, and char. |

| Landfill Diversion | Significantly reduces plastic waste in landfills and the environment. |

| Energy Generation | Produces alternative fuels and can make plants energy self-sufficient. |

| Circular Economy | Provides feedstocks for new plastics, reducing reliance on virgin materials. |

Ready to transform your plastic waste into valuable resources?

KINTEK specializes in advanced laboratory equipment and consumables for analyzing and optimizing processes like plastic pyrolysis. Whether you are researching feedstock quality, optimizing output yields, or scaling up your operation, our precise tools can help you achieve greater efficiency and profitability.

Contact our experts today to discuss how KINTEK's solutions can support your sustainable resource management goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- Why is precise temperature and strain rate control essential in Beryllium deformation? Optimize High-Temp Characterization

- Why is a powerful magnetic stirrer essential during photocatalytic degradation? Ensure Accurate Catalyst Performance

- What are some additional useful features in ultra-low freezers? Ensure Sample Integrity with Advanced Risk Mitigation

- What are the basic components of an IR spectrometer? A Guide to the Core Parts of FTIR Instruments

- How does Rotavapor work? Master Gentle, Low-Temperature Solvent Evaporation

- How does a Hot Isostatic Press (HIP) facilitate the transformation of CVD-ZnS? From Standard to Multispectral Grade

- What's the difference between hot and cold laminating? Choose the Right Method for Your Document

- What material is resistant to extreme heat? Match the Right Material to Your Extreme Application