At its core, press forging offers significant advantages in process control, component quality, and geometric complexity. Unlike impact-based methods, a forging press applies continuous, controlled pressure, allowing for superior material deformation, the creation of intricate shapes, and enhanced internal grain structure in the final product.

The primary advantage of press forging is not simply forming metal, but precisely controlling the material's flow and internal structure. This makes it the superior method for producing critical, high-performance components where strength, complexity, and consistency are non-negotiable.

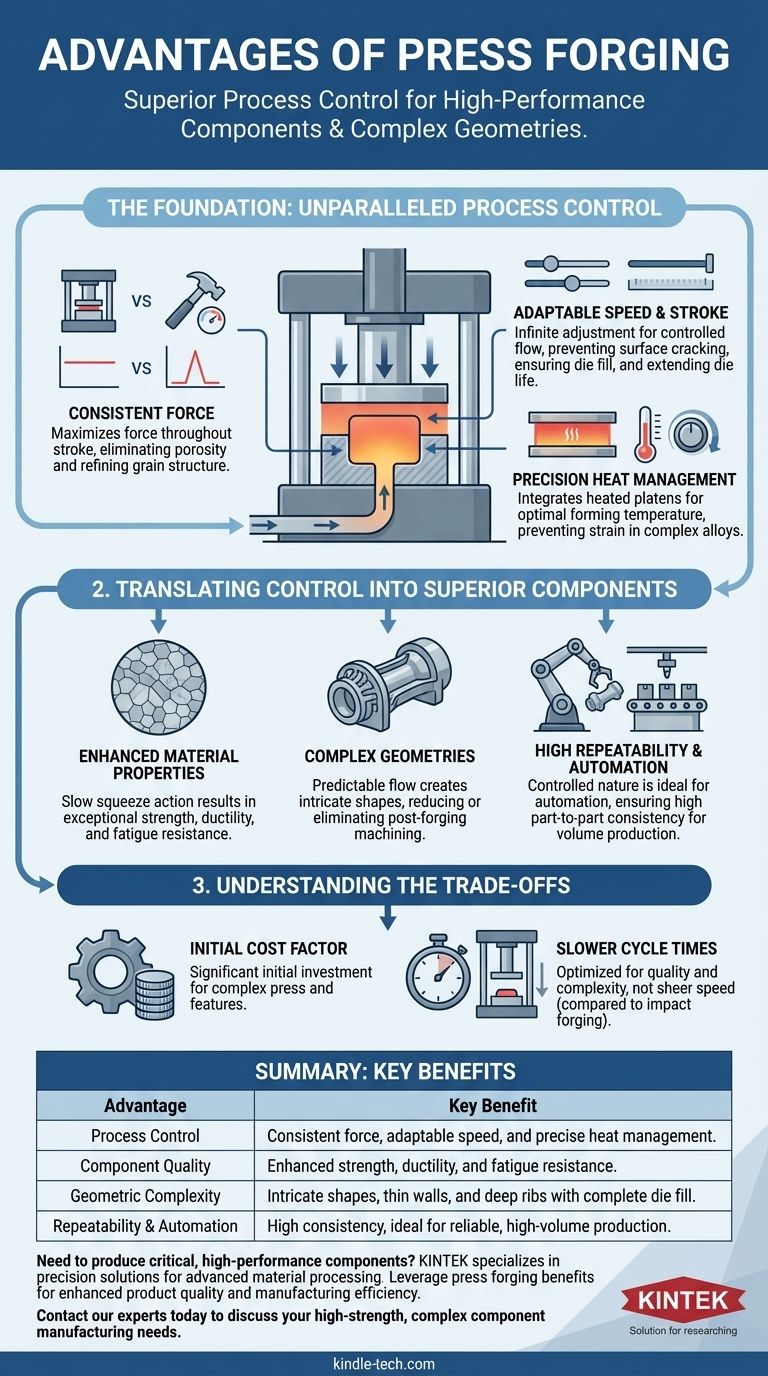

The Foundation: Unparalleled Process Control

The key benefits of press forging stem from its ability to precisely manage every aspect of the forming process. This level of control is what separates it from other manufacturing techniques.

Consistent Force Throughout the Stroke

A hydraulic forging press delivers its maximum rated force throughout the entire stroke. This is fundamentally different from a forging hammer, which delivers maximum energy only at the point of impact.

This sustained pressure ensures the workpiece material is fully consolidated, eliminating internal porosity and refining the metal's grain structure for superior mechanical properties.

Adaptable Speed and Stroke

Presses allow for infinite adjustment of the forming speed and stroke length. Slower, controlled speeds give the material time to flow properly into complex die cavities.

This controlled flow prevents surface cracking, ensures complete die fill, and significantly extends the service life of the forging dies, which are often a major cost center. The large slide stroke also makes it possible to form long or tall components.

Precision Heat Management

Hot forging, which is common in press applications, benefits from precise heat control. Modern presses can integrate heated platens that maintain the die and workpiece at an optimal temperature.

This allows for the forming of high-strength, difficult-to-shape alloys into complex geometries without inducing strain or compromising the material's integrity.

Translating Control into Superior Components

This granular control over the process directly translates into tangible benefits in the finished part.

Enhanced Material Properties

The slow, squeezing action of a press refines the internal grain structure of the metal in a way that impact forging cannot. This results in a finished part with exceptional strength, ductility, and fatigue resistance.

This is why press forging is the required method for many critical applications in the aerospace, defense, and energy sectors.

The Ability to Form Complex Geometries

Because the material flows slowly and predictably under sustained pressure, press forging excels at creating parts with intricate shapes, thin walls, and deep ribs.

This capability reduces or eliminates the need for extensive post-forging machining, saving both time and material costs on complex components.

High Repeatability and Automation

The controlled and predictable nature of a forging press makes it ideal for automation. Features like automated die loading, part handling, and scrap removal are common.

This leads to extremely high part-to-part consistency, making press forging a reliable choice for high-volume production runs where every component must meet identical specifications.

Understanding the Trade-offs

No process is perfect for every application. Being a trusted advisor means acknowledging the limitations.

The Initial Cost Factor

Hydraulic forging presses are complex machines, and the initial capital investment is significant. When coupled with features like heated platens and automation, the cost is higher than for simpler forging equipment.

This higher equipment and tooling cost can translate to a higher price per part, especially for simpler components.

Potentially Slower Cycle Times

The very nature of applying a slow, controlled squeeze means that the cycle time per part can be longer than with rapid-impact methods like hammer forging.

This makes press forging less suitable for producing simple, high-volume parts where speed is the primary driver of cost-effectiveness. The process is optimized for quality and complexity, not sheer speed.

Making the Right Choice for Your Application

Selecting the correct forging method requires aligning the process capabilities with your project's end goal.

- If your primary focus is maximum component complexity and material performance: Press forging is the definitive choice for creating intricate parts from high-strength alloys.

- If your primary focus is cost-effective production of simpler shapes: Other forging methods may offer a more economical solution, provided the part's mechanical requirements can be met.

- If your primary focus is part-to-part consistency in a high-volume run: The high degree of control and automation potential makes press forging an excellent option for ensuring quality at scale.

Understanding this balance between precision, complexity, and cost is the key to making a strategic and effective manufacturing decision.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Process Control | Consistent force, adaptable speed, and precise heat management for superior material deformation. |

| Component Quality | Enhanced strength, ductility, and fatigue resistance from refined internal grain structure. |

| Geometric Complexity | Ability to create intricate shapes, thin walls, and deep ribs with complete die fill. |

| Repeatability & Automation | High part-to-part consistency, ideal for reliable, high-volume production runs. |

Need to produce critical, high-performance components with superior strength and complex geometries?

KINTEK specializes in precision lab and manufacturing equipment, including solutions for advanced material processing. Our expertise can help you leverage the benefits of controlled processes like press forging to enhance your product quality and manufacturing efficiency.

Contact our experts today to discuss how our solutions can meet your specific needs for high-strength, complex component manufacturing.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the function of a laboratory hydraulic press in LZTC electrolyte pellet preparation? Optimize Ionic Conductivity

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What are the disadvantages associated with the KBr technique? Avoid Common Errors in IR Spectroscopy

- What role does mechanical pressing play in recycled graphite electrodes? Optimize Density and Performance

- How is heat generated in a hydraulic system? Identify and Manage Energy Loss for Efficiency

- What is rolling pressure? Master the Key to Material Deformation and Quality Control

- What is the function of a laboratory hydraulic press in solid-state battery assembly? Achieve Superior Densification

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions