In short, the primary advantages of sintered components are significant cost savings on complex parts, minimal material waste, and exceptional consistency across high-volume production runs. This is achieved by forming parts from metal powder, which allows for intricate geometries to be produced at or very near their final dimensions, drastically reducing the need for secondary machining.

Sintering is more than a manufacturing process; it is a method of materials engineering. It allows for the creation of components with precisely controlled properties by fusing powdered materials together on a microscopic level, offering a unique blend of design freedom, efficiency, and performance.

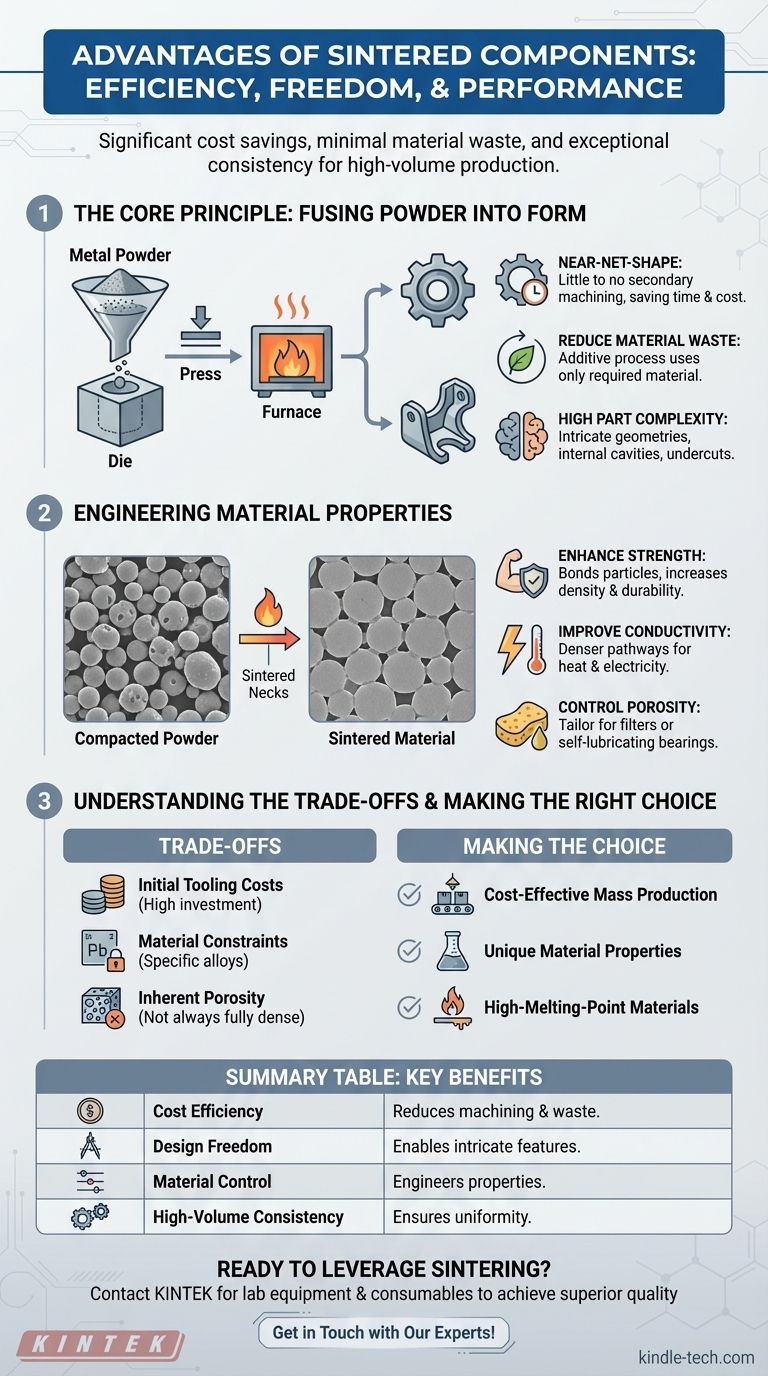

The Core Principle: Fusing Powder into Form

Sintering is a powder metallurgy process. It starts with a precise blend of metal powders which are compacted in a die and then heated to a temperature just below the material's melting point.

Creating Near-Net-Shape Components

The process forms parts that are extremely close to their final, or "net," shape. This fundamental characteristic is the source of many of its key benefits.

Because parts require little to no subsequent machining, processes like milling, turning, or grinding are often eliminated, saving significant time and cost.

Reducing Material Waste

Traditional subtractive manufacturing, like machining a part from a solid block, can generate substantial scrap material. Sintering is an additive process.

It uses only the material required for the component itself, making it a highly efficient and environmentally friendly option with minimal waste.

Achieving High Part Complexity

Compacting powder in a die enables the creation of complex and intricate geometries that are often difficult, expensive, or impossible to produce with other methods.

This includes features like internal cavities, non-machinable undercuts, and varying cross-sections, giving engineers immense design freedom for mass production.

Engineering Material Properties at the Microscopic Level

The sintering process fundamentally alters the material at a particle level, allowing for the precise engineering of its final characteristics.

Enhancing Strength and Integrity

The heating process causes the individual powder particles to bond, or form "sintered necks," at their contact points.

This significantly reduces the internal voids (porosity) from the compacted powder, dramatically increasing the part's density, strength, and overall durability.

Improving Thermal and Electrical Conductivity

As the porosity decreases and the material becomes denser, the pathways for heat and electricity become more direct. This results in improved thermal and electrical conductivity in the finished component.

Controlling Porosity for Specific Applications

While high density is often the goal, sintering offers the unique ability to intentionally control the level of porosity.

This is critical for applications like self-lubricating bearings (where pores hold oil) or filters, where a specific level of permeability is required.

Understanding the Trade-offs

No process is without its limitations. Objectively evaluating sintering requires understanding its specific constraints.

Initial Tooling Costs

The initial investment in creating the hardened steel dies used to compact the powder can be significant. This makes sintering most cost-effective for medium- to high-volume production runs where the tooling cost can be amortized over many parts.

Material Constraints

While versatile, the process works best with materials that can be readily powdered and possess good compression and sintering characteristics. Some alloys are not suitable for this method.

Inherent Porosity

Although sintering dramatically increases density, it can be difficult to eliminate porosity entirely. For extreme-stress applications requiring the absolute maximum strength, a fully dense material from a process like forging might be necessary.

Making the Right Choice for Your Application

Selecting sintering depends entirely on your project's specific priorities and constraints.

- If your primary focus is cost-effective mass production of complex parts: Sintering is an unparalleled choice due to its ability to create near-net-shape components with minimal waste and secondary processing.

- If your primary focus is unique material properties: Sintering offers precise control over density and porosity, enabling the creation of components like filters or self-lubricating bearings.

- If your primary focus is working with high-melting-point materials: Sintering allows you to form parts from materials like tungsten without having to reach their extreme melting temperatures, saving energy and cost.

Ultimately, choosing sintering empowers you to manufacture highly repeatable and intricate components with engineered properties in a cost-effective and efficient manner.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Cost Efficiency | Reduces machining needs and material waste for complex parts. |

| Design Freedom | Enables intricate geometries, undercuts, and internal features. |

| Material Control | Precisely engineers density, porosity, strength, and conductivity. |

| High-Volume Consistency | Ensures part-to-part uniformity in mass production. |

Ready to leverage the advantages of sintered components for your laboratory or production needs?

At KINTEK, we specialize in providing the precise lab equipment and consumables required for advanced powder metallurgy and sintering processes. Whether you're developing new materials or scaling up production, our solutions help you achieve superior part quality, reduce costs, and minimize waste.

Contact us today to discuss how we can support your project and help you unlock the full potential of sintering technology.

Get in touch with our experts now!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the different types of ovens in the lab? A Guide to Choosing the Right Heating Equipment

- What is the most common method used for synthesis of nanomaterials? A Guide to Dominant Techniques

- What are the applications of DC sputtering? Achieve High-Quality Conductive Coatings for Your Industry

- What are the methods used in sample preparation? A Guide to Extraction, Cleanup, and Concentration

- How is a crucible used in the crucible? Unpacking Arthur Miller's Powerful Metaphor

- How does a magnetic stirrer influence the efficiency of the sulfuric acid leaching process for zinc ash? Expert Insights

- What is the best way to join stainless steel? A Guide to Welding, Brazing, and Fastening

- What are batch type furnaces? A Guide to Flexible, Controlled Thermal Processing