Proper preparation is the most critical phase of any electrochemical experiment. Before using a flat plate corrosion electrolytic cell, you must follow a strict, multi-step process that includes inspection, cleaning, solution preparation, and careful assembly. These steps are not procedural formalities; they are the foundation for acquiring accurate, repeatable, and meaningful data.

The quality of your experimental results is determined before the potentiostat is ever turned on. Meticulous preparation is the only way to ensure that you are measuring the true corrosion behavior of your material, rather than the effects of contamination, leaks, or faulty setup.

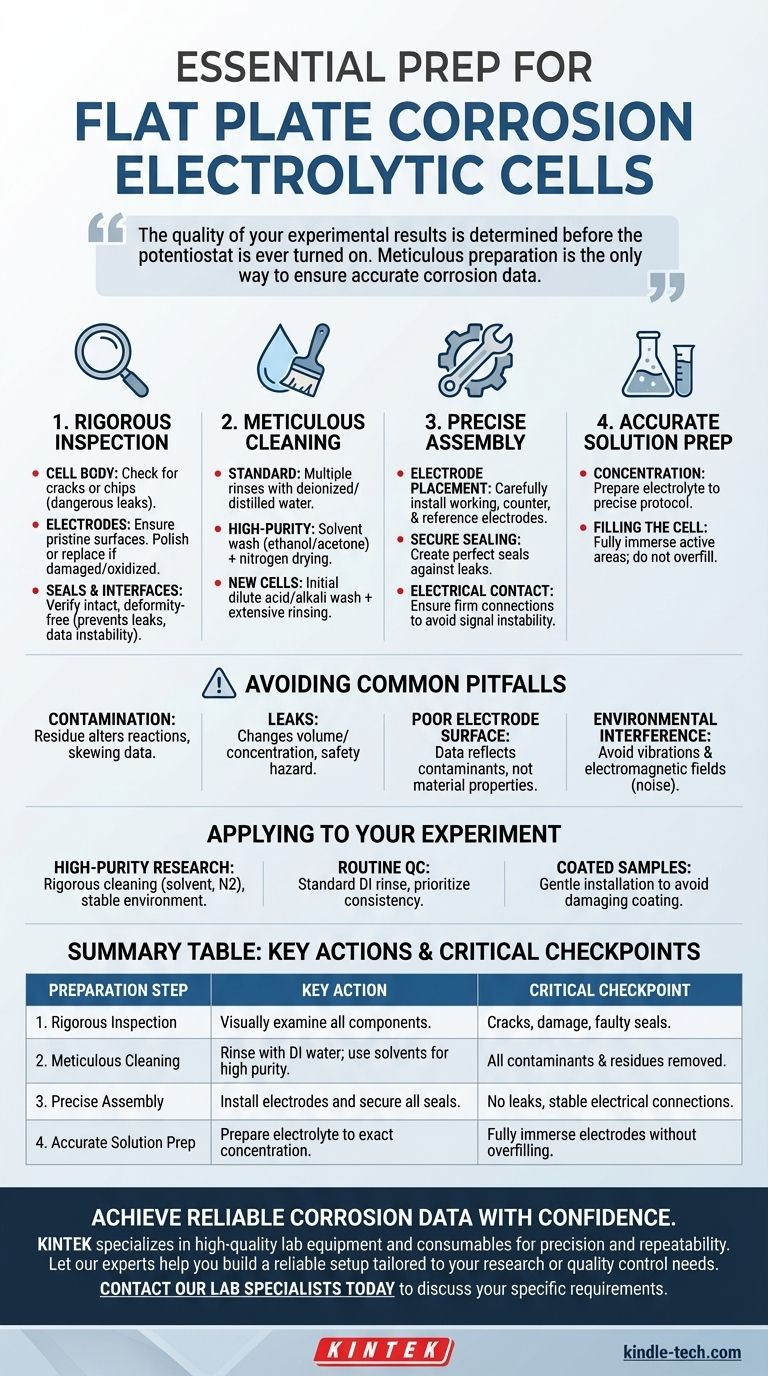

The Four Pillars of Pre-Experiment Preparation

A successful corrosion study relies on a controlled environment where the only variables are the ones you intend to study. The following four steps are designed to eliminate unwanted variables and establish that control.

Step 1: Rigorous Inspection

Before any cleaning or assembly, conduct a thorough visual inspection of all components.

- Cell Body: Check the cell, especially if it's glass or has a viewing window, for any cracks or chips. A compromised cell body can lead to dangerous electrolyte leaks.

- Electrodes: Examine the surfaces of the working, counter, and reference electrodes. The working electrode should be pristine. If you see any signs of oxidation, residue, or physical damage, it must be cleaned, polished, or replaced.

- Seals and Interfaces: Verify that all seals, O-rings, and electrode interfaces are intact and free from deformities. A faulty seal is a primary cause of leaks and data instability.

Step 2: Meticulous Cleaning

Contaminants can drastically alter electrochemical reactions, acting as inhibitors or accelerators and invalidating your results.

- Standard Protocol: For routine use, start by rinsing all components with tap water to remove loose debris, followed by multiple, thorough rinses with deionized or distilled water.

- High-Purity Protocol: For more sensitive experiments, after the water rinse, clean the cell with an organic solvent like ethanol or acetone to remove organic residues. Finally, dry the components with a gentle stream of nitrogen or dry air.

- New Cells: A brand-new cell may have manufacturing residues. An initial wash with a dilute acid or alkali solution, followed by extensive rinsing with deionized water, is often necessary.

Step 3: Precise Assembly and Installation

Correct assembly ensures the geometric and electrical integrity of your electrochemical system.

- Electrode Placement: Carefully install the working electrode (your sample), counter electrode, and reference electrode into their designated ports.

- Secure Sealing: Ensure each component is seated correctly to create a perfect seal with the cell body. This is your primary defense against electrolyte leakage.

- Electrical Contact: Verify that the electrical connections to the electrodes are firm. Poor contact introduces unwanted resistance or signal instability, which will corrupt your voltage and current measurements.

Step 4: Accurate Solution Preparation

The electrolyte is a central component of the experiment and must be prepared correctly.

- Concentration: Prepare your electrolyte solution to the precise concentration required by your experimental protocol.

- Filling the Cell: Pour the solution into the cell, adding enough to fully immerse the active areas of all three electrodes. Do not overfill, as this can lead to spills during final assembly or temperature changes.

Understanding the Common Pitfalls

Skipping or rushing preparation steps introduces errors that are often impossible to correct for after the fact. Understanding these risks highlights the importance of diligence.

The Cost of Contamination

Any residue left in the cell or on an electrode—be it dust, oil from your hands, or leftover cleaner—can participate in electrochemical reactions. This will skew your measurements, making it appear your material is more or less corrosion-resistant than it actually is.

The Risk of Leaks

An electrolyte leak is more than just a mess. It changes the volume and concentration of your solution mid-experiment, harms lab equipment, and can pose a significant safety hazard depending on the chemical nature of the electrolyte.

The Problem of a Poor Electrode Surface

The goal is to test your material, not a layer of oxide or contaminants on its surface. An improperly prepared working electrode means your data will not reflect the true properties of the material. Likewise, a faulty or improperly calibrated reference electrode renders all potential measurements meaningless.

The Impact of Environmental Interference

Electrochemical measurements are often sensitive. Ensure your experimental setup is placed in a stable environment, free from significant vibrations or strong electromagnetic fields (e.g., from other lab equipment), which can introduce noise into your data.

Applying This to Your Experiment

Your specific preparation protocol may vary slightly based on the precision your work demands.

- If your primary focus is high-purity materials research: You must follow the most rigorous cleaning protocol, including a solvent wash and nitrogen drying, and ensure a stable environment.

- If your primary focus is routine quality control or screening: A standard deionized water rinse may be sufficient, but consistency across all tests is absolutely critical for comparable results.

- If your primary focus is testing coated samples: Be especially gentle during installation to avoid scratching or damaging the coating, which would create an artificial failure point.

By treating preparation with the same seriousness as data analysis, you ensure your efforts yield reliable and valuable scientific insight.

Summary Table:

| Preparation Step | Key Action | Critical Checkpoint |

|---|---|---|

| 1. Rigorous Inspection | Visually examine all components. | Check for cracks, damage, and faulty seals. |

| 2. Meticulous Cleaning | Rinse with DI water; use solvents for high purity. | Remove all contaminants and residues. |

| 3. Precise Assembly | Install electrodes and secure all seals. | Ensure no leaks and stable electrical connections. |

| 4. Accurate Solution Prep | Prepare electrolyte to exact concentration. | Fully immerse electrodes without overfilling. |

Achieve reliable corrosion data with confidence. Proper cell preparation is non-negotiable for accurate electrochemical testing. KINTEK specializes in high-quality lab equipment and consumables, including durable corrosion cells and electrodes designed for precision and repeatability. Let our experts help you build a reliable setup tailored to your research or quality control needs.

Contact our lab specialists today to discuss your specific requirements and ensure your experiments start on a solid foundation.

Visual Guide

Related Products

- Flat Corrosion Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What is a flat cell for corrosion testing? Achieve Non-Destructive, In-Situ Analysis

- What is the operating principle of a flat plate corrosion electrolytic cell? A Guide to Controlled Materials Testing

- What are the advantages of a three-electrode flat electrolytic cell? Precise Corrosion Analysis for 1020C Steel

- What are the complete post-experiment procedures for a flat plate corrosion electrolytic cell? A Step-by-Step Guide to Reliable Results

- What is the difference between electrolytic corrosion cell and electrochemical corrosion cell? Understand the Driving Force Behind Corrosion