In short, Chemical Vapor Deposition (CVD) processes are primarily categorized by their operating pressure and the energy source used to initiate the reaction. The main pressure-based types are Atmospheric Pressure (APCVD) and Low-Pressure (LPCVD), while the main energy-based types are conventional Thermal CVD and Plasma-Enhanced CVD (PECVD). Each variant is engineered to achieve specific film properties on different types of materials.

The core difference between CVD types comes down to a fundamental trade-off: the process conditions required to create a high-quality film versus the limitations of the material being coated. Choosing a specific CVD process is about balancing temperature, pressure, and cost to achieve the desired outcome.

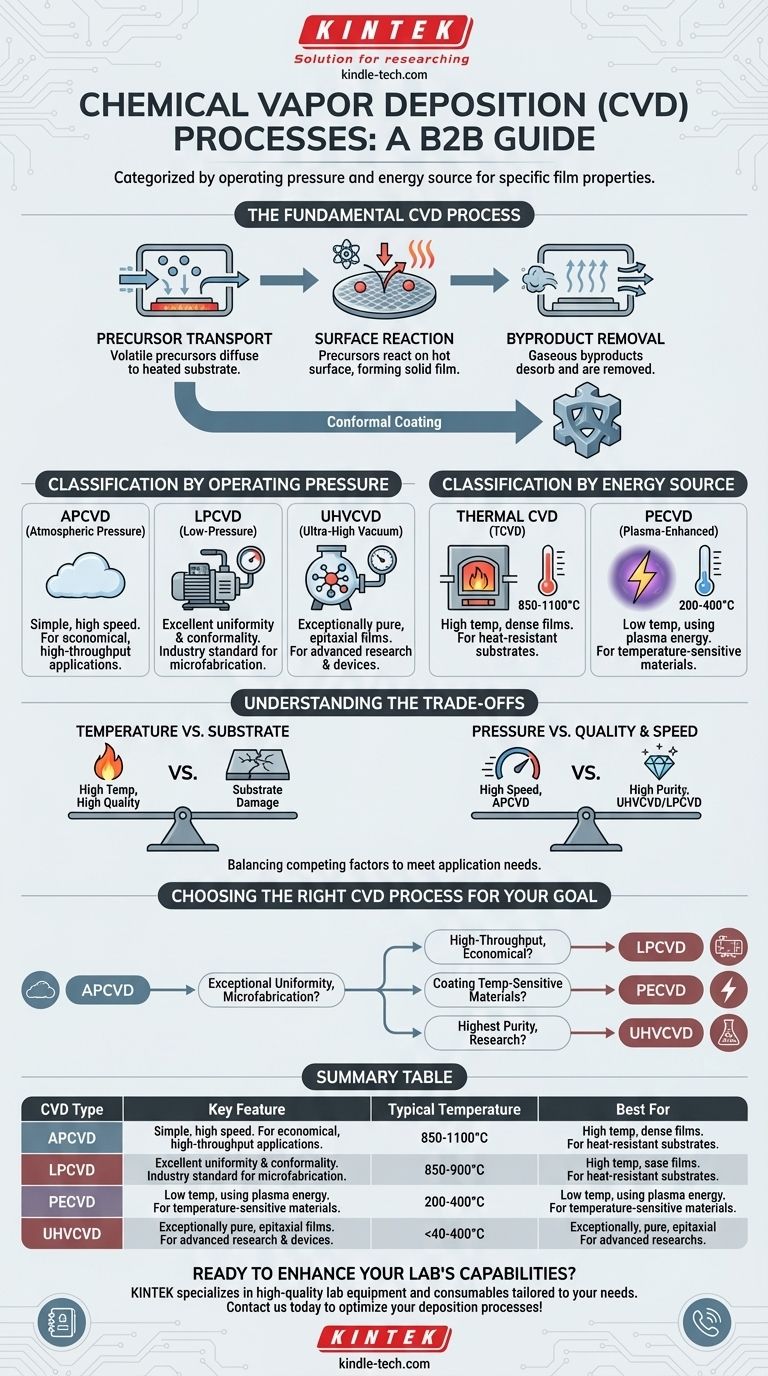

The Fundamental CVD Process

Before exploring the different types, it's essential to understand the core mechanism they all share. Every CVD process involves introducing reactive gases (precursors) into a chamber where they decompose and react on a heated surface (the substrate) to form a solid thin film.

Step 1: Precursor Transport

Volatile precursor gases are transported into a reaction chamber and diffuse through a boundary layer to reach the substrate surface.

Step 2: Surface Reaction

The precursor gases are adsorbed onto the hot substrate. The thermal energy (or other energy source) breaks their chemical bonds, causing a reaction that deposits the desired solid material.

Step 3: Byproduct Removal

Gaseous byproducts from the reaction are desorbed from the surface and transported out of the chamber, leaving behind a pure, solid film.

Classification by Operating Pressure

One of the most critical process parameters is the pressure inside the reaction chamber. This directly influences the deposition rate, film uniformity, and purity.

Atmospheric Pressure CVD (APCVD)

This process is conducted at standard atmospheric pressure. Its main advantage is simplicity and high deposition speed, making it suitable for applications where cost and throughput are more critical than ultimate film perfection.

Low-Pressure CVD (LPCVD)

Operating at sub-atmospheric pressures, LPCVD is a workhorse in the semiconductor industry. The lower pressure reduces unwanted gas-phase reactions and improves the diffusion of precursors, resulting in films with excellent uniformity and conformality, even over complex shapes.

Ultra-High Vacuum CVD (UHVCVD)

This is an extreme version of LPCVD, operating at pressures below 10⁻⁶ Pa. The ultra-high vacuum minimizes contamination, allowing for the growth of exceptionally pure, epitaxial (single-crystal) films required for advanced microelectronics.

Classification by Energy Source

The method used to provide the energy needed to break down the precursor gases is another key differentiator. This choice often dictates the required process temperature.

Thermal CVD (TCVD)

This is the conventional form of CVD, where the reaction is driven purely by the high temperature of the substrate, typically between 850-1100°C. This method produces high-quality, dense films but is only suitable for substrates that can withstand extreme heat.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate plasma (an ionized gas). This plasma provides the energy to break apart the precursor molecules, allowing the deposition to occur at much lower temperatures (typically 200-400°C). This makes it possible to coat temperature-sensitive materials like polymers or completed electronic devices.

Understanding the Trade-offs

No single CVD method is universally superior. The choice always involves balancing competing factors to meet the application's specific needs.

Temperature vs. Substrate Compatibility

The primary trade-off is between process temperature and material limitations. Thermal CVD produces excellent, highly crystalline films but is incompatible with many substrates. PECVD solves this by lowering the temperature, but the plasma can sometimes affect the film's chemical structure or cause minor substrate damage.

Pressure vs. Quality and Speed

Lowering the pressure, as in LPCVD and UHVCVD, dramatically improves film uniformity and purity. However, this comes at the cost of a slower deposition rate and requires more complex and expensive vacuum equipment compared to the faster, simpler APCVD process.

Conformality: A Universal Strength

A key advantage of most CVD techniques is their ability to produce conformal coatings. Because the precursor is a gas, it can reach and coat all surfaces of a complex, three-dimensional object uniformly, a property referred to as good "wrap-around."

Choosing the Right CVD Process for Your Goal

Your final decision should be guided by the specific requirements of your film and the constraints of your substrate.

- If your primary focus is high-throughput, economical coating on heat-resistant substrates: APCVD is often the most practical choice due to its speed and simplicity.

- If your primary focus is exceptional film uniformity and purity for microfabrication: LPCVD is the industry standard for achieving high-quality films over large areas.

- If your primary focus is coating temperature-sensitive materials like plastics or electronics: PECVD is the essential method, as it enables high-quality deposition without thermal damage.

- If your primary focus is achieving the highest possible purity and crystalline perfection for research or advanced devices: UHVCVD is the necessary tool, despite its complexity and slow speed.

Ultimately, understanding the different types of CVD empowers you to precisely control the synthesis of materials atom by atom.

Summary Table:

| CVD Type | Key Feature | Typical Temperature | Best For |

|---|---|---|---|

| APCVD | Atmospheric pressure, high speed | High | High-throughput, economical coating |

| LPCVD | Low pressure, high uniformity | High | Microfabrication, uniform films |

| PECVD | Plasma-enhanced, low temperature | 200-400°C | Temperature-sensitive materials |

| UHVCVD | Ultra-high vacuum, high purity | Varies | Advanced research, epitaxial films |

Ready to enhance your lab's capabilities with the right CVD process? KINTEK specializes in providing high-quality lab equipment and consumables tailored to your laboratory's unique needs. Whether you're working with temperature-sensitive materials or require ultra-pure films for advanced research, our expertise in CVD technology can help you achieve superior results. Contact us today to discuss your specific requirements and discover how our solutions can optimize your deposition processes!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Which of the following metals are used as catalysts to synthesize CNT? Discover the Top Catalysts for High-Quality CNT Growth

- What is sputtering in semiconductors? A Guide to Precision Thin Film Deposition

- What is Thermally Activated Chemical Vapor Deposition (TACVD)? High-Purity Coating for Heat-Resistant Materials

- How many types of physical Vapour deposition are there? A Guide to Evaporation vs. Sputtering

- How does pressure affect deposition rate? Master the Balance Between Speed and Film Quality

- What is thermally activated CVD? The Essential Guide to High-Temperature Thin Film Deposition

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What role does a high-temperature CVD furnace play in synthesis of Mo2C crystals? Achieve Atomic-Level Precision