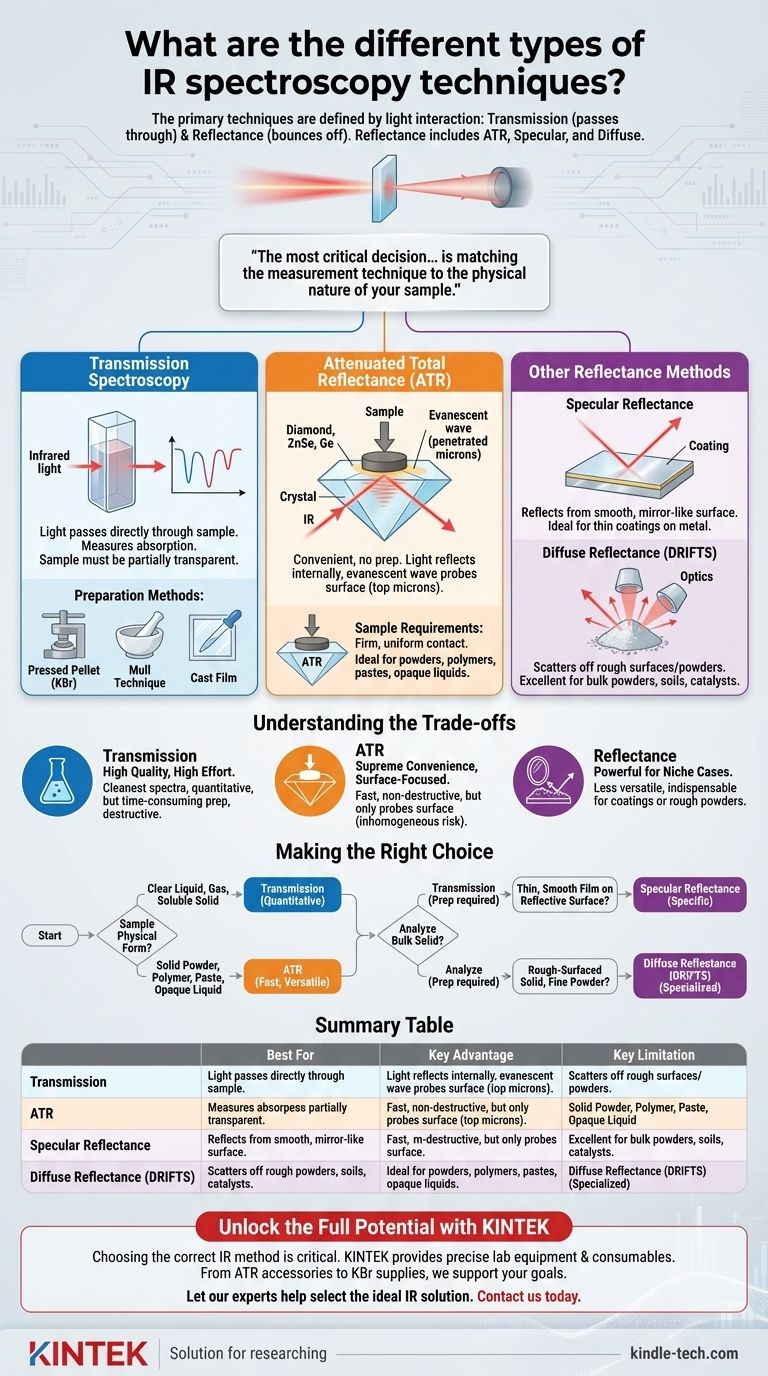

The primary techniques in IR spectroscopy are defined by how the infrared light interacts with the sample, not just how the sample is prepared. The main methods are Transmission, where light passes through the sample, and Reflectance, where light bounces off the sample. Reflectance itself is further divided into key techniques like Attenuated Total Reflectance (ATR), Specular Reflectance, and Diffuse Reflectance.

The most critical decision in IR spectroscopy is matching the measurement technique to the physical nature of your sample. The choice between Transmission, ATR, or another reflectance method dictates everything from sample preparation to the type of information you can obtain.

The Foundation: Transmission Spectroscopy

Transmission is the classic IR spectroscopy method. It operates on a straightforward principle: IR light is passed directly through a sample, and the detector measures how much light was absorbed at each wavelength.

How It Works

The spectrophotometer directs a beam of infrared radiation through the sample. The amount of light that makes it to the detector is compared against the initial intensity of the beam. The resulting spectrum shows "troughs" where the sample's molecules absorbed the energy.

Sample Requirements

For a successful transmission measurement, the sample must be partially transparent to infrared light. If it's too thick or too concentrated, it will absorb all the light, yielding a useless spectrum. This is why extensive sample preparation is often required for solids and concentrated liquids.

Common Preparation for Transmission

This is where the methods you may have heard of—like mulls and pellets—come into play. They are not measurement techniques themselves, but rather methods to prepare a solid for a transmission measurement.

- Pressed Pellet (KBr): The solid sample is finely ground with an IR-transparent salt (potassium bromide, KBr) and compressed under high pressure to form a thin, transparent disc.

- Mull Technique: The solid is ground into a fine paste with a mulling oil (like Nujol). This paste is then spread between two IR-transparent windows.

- Cast Film: A solid is dissolved in a volatile solvent. A drop of the solution is placed on an IR-transparent window, and the solvent is evaporated to leave a thin film of the sample.

The Modern Workhorse: Attenuated Total Reflectance (ATR)

ATR has become the most common IR technique in modern labs due to its sheer convenience. It is a reflectance method that allows for the analysis of solid and liquid samples with little to no preparation.

How It Works

Instead of passing light through the sample, the IR beam is directed into a special, high-refractive-index crystal (often diamond, zinc selenide, or germanium). At the crystal's surface, the light creates a very shallow, non-propagating "evanescent wave" that penetrates a few micrometers into the sample placed in tight contact with it.

The instrument measures how this wave is "attenuated" or absorbed by the sample. Because it only probes the very top surface, even completely opaque samples can be analyzed easily.

Sample Requirements

The only requirement is that the sample can make firm, uniform contact with the ATR crystal. This makes it ideal for powders, polymer sheets, viscous liquids, pastes, and even soft solids.

Specialized Tools: Other Reflectance Methods

When ATR isn't suitable, other reflectance techniques are used for specific types of samples where light must bounce off the surface.

Specular Reflectance

This technique measures the IR light that is reflected directly from a smooth, mirror-like surface. It is the ideal method for analyzing thin coatings on reflective substrates, such as a polymer coating on a metal panel.

Diffuse Reflectance (DRIFTS)

Short for Diffuse Reflectance Infrared Fourier Transform Spectroscopy, this method is designed for rough-surfaced solids and powders. The IR light scatters off the irregular surface in many directions. Special optics collect this "diffusely scattered" light to generate a spectrum. It is excellent for analyzing pharmaceutical powders, soils, and catalysts.

Understanding the Trade-offs

Choosing a technique requires balancing convenience, sample type, and the analytical goal.

Transmission: High Quality, High Effort

Transmission often provides the "cleanest," highest-quality spectra, which is ideal for quantitative analysis. However, the required sample preparation (e.g., making a KBr pellet) can be time-consuming, destructive to the sample, and requires skill to perform correctly.

ATR: Supreme Convenience, Surface-Focused

ATR is incredibly fast and non-destructive, requiring you to simply press a sample onto the crystal and measure. Its primary limitation is that it is a surface technique. It only analyzes the top few microns, which may not be representative of the bulk material if the sample is inhomogeneous.

Reflectance: Powerful for Niche Cases

Specular and Diffuse Reflectance are less versatile than ATR but are indispensable for the specific sample types they were designed for. Attempting to analyze a coating on metal or a rough powder with another technique would likely yield poor or no results.

Making the Right Choice for Your Goal

Your sample's physical form is the primary guide for selecting the correct IR technique.

- If you have a clear liquid, gas, or soluble solid: Transmission is the classic and most quantitative approach.

- If you have a solid powder, polymer, paste, or opaque liquid: Start with ATR. It is the fastest, easiest, and most versatile method for the majority of samples.

- If you need to analyze the bulk of a solid and not just its surface: Use Transmission, which will require preparing a KBr pellet or a mull.

- If you are analyzing a thin, smooth film on a reflective surface: Specular Reflectance is the only technique designed for this task.

- If you are analyzing a rough-surfaced solid or a fine powder: Diffuse Reflectance (DRIFTS) will provide the best possible spectrum.

Ultimately, selecting the right technique ensures your spectral data is a true and accurate representation of your sample's chemical composition.

Summary Table:

| Technique | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Transmission | Clear liquids, gases, soluble solids | High-quality, quantitative spectra | Requires extensive sample preparation (e.g., KBr pellets) |

| ATR | Powders, polymers, pastes, opaque liquids | Minimal to no sample preparation, fast analysis | Only probes the surface (top few microns) |

| Specular Reflectance | Thin films on reflective surfaces (e.g., coatings on metal) | Ideal for analyzing surface coatings | Requires a smooth, mirror-like surface |

| Diffuse Reflectance (DRIFTS) | Rough solids, fine powders (e.g., catalysts, soils) | Excellent for analyzing bulk powders without dissolution | Requires specialized optics |

Unlock the Full Potential of Your Samples with the Right IR Technique

Choosing the correct IR spectroscopy method is critical for obtaining accurate, reliable data. Whether your lab needs the high-quality spectra of Transmission, the convenience of ATR, or the specialized capabilities of Reflectance methods, having the right equipment is key.

KINTEK specializes in providing the precise lab equipment and consumables your laboratory needs. From robust ATR accessories to supplies for preparing KBr pellets, we support your analytical goals with reliable, high-performance products.

Let our experts help you select the ideal IR solution for your specific applications. Contact us today to discuss your requirements and ensure your lab is equipped for success.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Lab Infrared Press Mold

- Infrared High Resistance Single Crystal Silicon Lens

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- What are the different types of sieving machines? Choose the Right Motion for Your Material

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results