While hailed for their flexibility and use of recycled materials, Electric Arc Furnaces (EAFs) are not a universal solution for steelmaking. Their primary disadvantages stem from a heavy dependence on the quality and cost of scrap steel, massive electrical power requirements, and inherent challenges in producing the highest grades of steel. These factors create significant economic and operational hurdles compared to traditional methods.

The core trade-off of the Electric Arc Furnace is accepting volatility for flexibility. While EAFs offer lower capital costs and a smaller footprint, they expose operators to fluctuating electricity prices, unpredictable scrap quality, and limitations in final product purity.

The Challenge of Raw Material Dependency

The single greatest constraint of an EAF is its reliance on external inputs, primarily scrap steel. This dependency creates issues with both cost and quality.

Volatility in Scrap Metal Markets

An EAF's profitability is directly tied to the price of scrap steel, which is a globally traded and often volatile commodity.

Unlike an integrated mill that controls its iron source through a blast furnace, an EAF operator is a price-taker in the scrap market. This can lead to unpredictable and sometimes rapidly escalating production costs.

The Problem of "Tramp Elements"

Scrap steel is not pure iron. It contains residual or "tramp" elements like copper, tin, nickel, and chromium from its previous life.

These elements are difficult and costly to remove in the EAF process. High concentrations of tramp elements, especially copper, can degrade the steel's mechanical properties, making it unsuitable for demanding applications like deep-drawing automotive body panels.

Limitations with Virgin Iron

To dilute tramp elements and produce higher-quality steel, EAFs can use virgin iron sources like Direct Reduced Iron (DRI) or Hot Briquetted Iron (HBI).

However, melting DRI requires even more electrical energy than melting scrap, further increasing operating costs. The EAF is less efficient at processing large quantities of virgin material compared to a Basic Oxygen Furnace (BOF), which is designed for it.

High and Volatile Operating Costs

Beyond raw materials, the direct operating costs of an EAF are significant and subject to market forces outside the operator's control.

Extreme Electrical Energy Consumption

An EAF consumes a massive amount of electricity—roughly 400 kWh per ton of steel—to melt the metallic charge.

This makes the operation highly sensitive to electricity price fluctuations and grid reliability. In regions with expensive or unstable power, EAFs can become economically unviable.

Graphite Electrode and Refractory Costs

The furnace uses large graphite electrodes to conduct the electricity that forms the arc. These electrodes are consumed during operation and represent a major, recurring cost.

Furthermore, the intense, focused heat of the electric arc causes significant wear on the refractory lining of the furnace, necessitating frequent maintenance, downtime, and costly replacement.

Understanding the Trade-offs

The disadvantages of the EAF are best understood in comparison to its primary alternative, the integrated route using a Basic Oxygen Furnace (BOF).

EAF vs. BOF: A Question of Quality

The BOF process begins with molten iron of a known, high purity from a blast furnace. This gives operators precise control over the final chemistry.

For this reason, the BOF route has traditionally dominated the production of high-specification flat-rolled steels for the automotive and appliance industries, where purity is paramount. EAFs struggle to consistently meet these exacting standards without using expensive, high-purity raw materials.

Scale and Productivity Differences

EAF plants, or "mini-mills," are typically smaller and produce less annual tonnage than large, integrated BOF steelworks.

While an EAF's "tap-to-tap" time can be under an hour, the overall output of a major integrated site with multiple large BOFs is significantly higher, offering economies of scale that EAFs cannot match.

Environmental Footprint: The Hidden CO2

EAF steelmaking is often cited for its lower direct CO2 emissions. However, this is only part of the story.

The environmental benefit is highly dependent on the source of its electricity. If the power grid is fed by fossil fuels like coal or natural gas, the EAF's "Scope 2" emissions can be substantial, merely offshoring the carbon footprint rather than eliminating it.

Making the Right Choice for Your Goal

Selecting between EAF and other steelmaking processes depends entirely on your strategic objectives, from product mix to capital constraints.

- If your primary focus is construction-grade steel (rebar, beams): The EAF is the ideal choice due to its cost-effectiveness in processing scrap into products where tramp elements are less critical.

- If your primary focus is high-purity flat steel for automotive exteriors: The traditional BOF route remains the most reliable and cost-effective path for high-volume production, though advancements in EAF technology are closing the gap.

- If your primary focus is minimizing initial investment and maximizing speed to market: The EAF "mini-mill" model offers a dramatically lower capital cost and faster construction timeline than a full integrated steelworks.

- If your primary focus is environmental impact: The EAF is only the greener option when powered by a grid with a high percentage of renewable or nuclear energy.

Ultimately, understanding these disadvantages allows you to leverage the EAF's strengths strategically while mitigating its inherent risks.

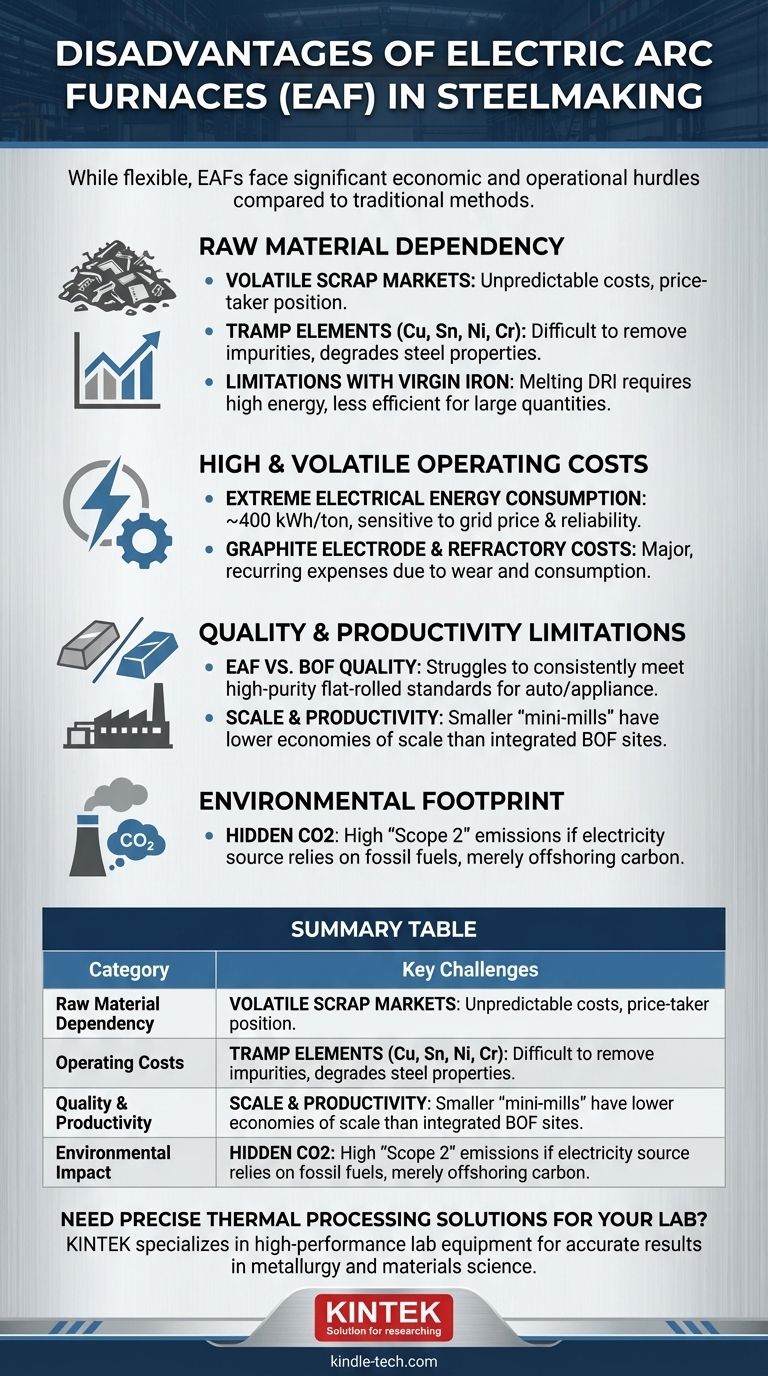

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Raw Material Dependency | Volatile scrap prices, tramp elements (e.g., copper), high cost of virgin iron (DRI/HBI) |

| Operating Costs | Massive electricity consumption (~400 kWh/ton), high graphite electrode and refractory wear |

| Quality & Productivity | Limitations in producing high-purity flat steel, lower economies of scale vs. BOF |

| Environmental Impact | High Scope 2 CO2 emissions if grid relies on fossil fuels |

Need precise thermal processing solutions for your lab? KINTEK specializes in high-performance lab equipment and consumables, helping you achieve accurate, reliable results while managing operational costs. Whether you're in metallurgy, materials science, or quality control, our furnaces and lab tools are designed for efficiency and durability. Contact us today to explore how KINTEK can support your laboratory's unique needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of catalyst in plastic pyrolysis? Boost Oil Yield & Lower Costs

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- Which furnace can produce high temperature? Choose the Right High-Temp Furnace for Your Process

- Why is it necessary to use a high-vacuum furnace during Active Metal Brazing (AMB)? Ensure Perfect Ceramic-to-Metal Bonds

- How hot can an electric furnace get? A Guide to Temperature Ranges and Applications

- What is sintering in a furnace? A Guide to Creating Strong, Dense Parts from Powder

- How does heat affect tensile strength? Understand the Strength-Ductility Trade-Off

- What are the disadvantages of sintering process? Key Limitations in Density, Cost, and Size