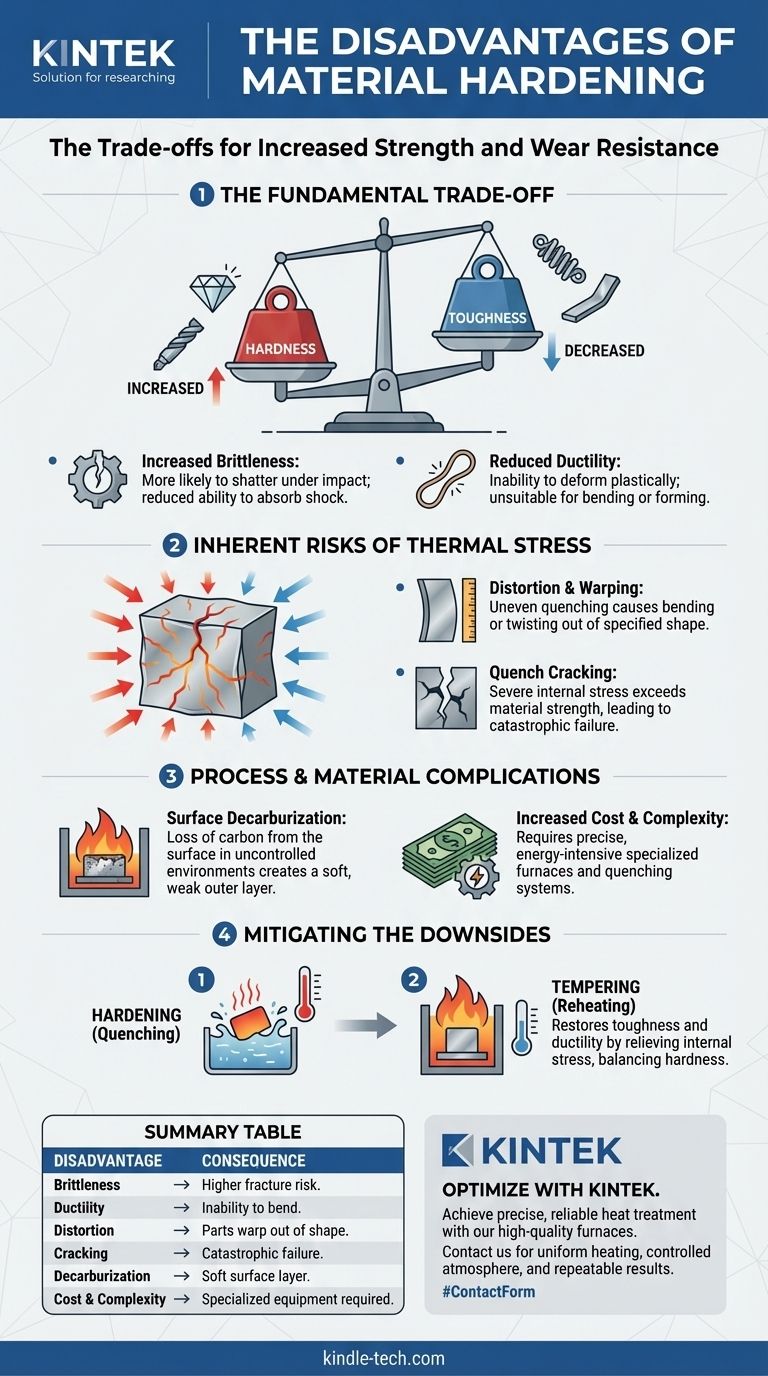

While hardening is essential for increasing a material's strength and wear resistance, the process is not without significant drawbacks. The primary disadvantages are a dramatic increase in brittleness and the introduction of internal stresses, which can lead to dimensional distortion, warping, and even cracking of the component.

The core issue with hardening is that the same rapid thermal process that creates a hard, strong microstructure also generates immense internal stress. This fundamental trade-off means that as hardness increases, the material's ability to deform under load decreases, making it more susceptible to fracture.

The Fundamental Trade-off: Hardness vs. Toughness

Hardening forces a compromise between two critical material properties. You gain strength in one area by sacrificing resilience in another.

Increased Brittleness

The most significant disadvantage of hardening is the inverse relationship between hardness and toughness. A hardened material is more brittle, meaning it is more likely to shatter or fracture when subjected to sudden impact or shock.

Instead of bending or deforming, a hardened part will simply break once its elastic limit is exceeded.

Reduced Ductility

Hardening also severely reduces a material's ductility. This is the ability of a material to be stretched or deformed without breaking.

This makes the material unsuitable for applications that require forming, bending, or the ability to absorb energy through plastic deformation.

The Inherent Risks of Thermal Stress

The process of hardening involves extreme temperature changes, which create significant stress within the material's internal structure. Managing this stress is the primary challenge.

Distortion and Warping

The rapid cooling, or quenching, central to the hardening process is rarely perfectly uniform. Different sections of a part cool at slightly different rates, causing them to contract unevenly.

This uneven contraction creates powerful internal forces that can cause the part to warp, bend, or twist out of its specified shape. This is a major concern for components that require tight dimensional tolerances.

The Danger of Quench Cracking

If the internal stresses induced during quenching are too severe, they can exceed the ultimate strength of the material itself. This results in quench cracking.

These cracks can be microscopic or large enough to cause catastrophic failure of the part. Features like sharp corners, holes, or sudden changes in cross-section are especially vulnerable as they act as stress concentrators.

Process and Material Complications

Beyond the physical changes to the part, the hardening process itself introduces complexity and potential for error.

Surface Decarburization

If hardening is not performed in a controlled environment like a vacuum furnace, the high heat can cause carbon to leave the surface of the steel. This creates a soft, weak outer layer, which often defeats the purpose of the hardening process.

Increased Cost and Complexity

Hardening is a precise, energy-intensive process. It requires specialized furnaces capable of reaching high temperatures and sophisticated quenching systems.

This adds significant cost and complexity to the manufacturing workflow compared to using a material in its non-hardened, or annealed, state.

Mitigating the Downsides

Because of these disadvantages, hardened parts almost always require a subsequent heat treatment process to be viable for real-world use.

The Necessity of Tempering

To relieve the internal stresses and reduce brittleness, hardened parts are typically tempered. This involves reheating the part to a lower temperature and holding it for a specific time.

Tempering restores some of the material's toughness and ductility. However, this comes at the cost of reducing some of the peak hardness gained during the initial quench. The final properties are a carefully controlled balance achieved through these two steps.

Designing for Heat Treatment

Engineers must design parts with the hardening process in mind. This includes using generous radii on corners, avoiding abrupt changes in thickness, and specifying materials with good hardenability to minimize the risk of distortion and cracking.

Making the Right Choice for Your Application

Understanding these disadvantages is key to deciding if hardening is the appropriate process for your component.

- If your primary focus is extreme wear resistance and compressive strength: Hardening is often necessary, but you must design the component to be supported and protected from impact (e.g., cutting tools, bearings).

- If your primary focus is impact resistance and durability: A tougher, less hard material is a better choice, or you must employ a tempering process that restores significant toughness at the expense of hardness (e.g., structural steel, vehicle axles).

- If your primary focus is maintaining precise dimensions: You must account for potential distortion and may need to budget for post-hardening machining, or choose a material and process known for dimensional stability.

Ultimately, hardening is a powerful tool for enhancing material properties, but it must be applied with a clear understanding of its inherent compromises.

Summary Table:

| Disadvantage | Consequence |

|---|---|

| Increased Brittleness | Higher risk of fracture under impact or shock loads. |

| Reduced Ductility | Inability to bend or deform plastically without breaking. |

| Distortion & Warping | Parts bend or twist out of shape due to uneven quenching. |

| Quench Cracking | Severe internal stress can cause catastrophic part failure. |

| Surface Decarburization | Loss of carbon from the surface creates a soft, weak layer. |

| Higher Cost & Complexity | Requires specialized equipment and precise process control. |

Optimize Your Heat Treatment Process with KINTEK

Hardening is a delicate balance. The right equipment and consumables are critical for minimizing distortion, preventing cracking, and achieving the perfect balance of hardness and toughness for your specific application.

KINTEK specializes in high-quality lab furnaces and thermal processing equipment designed for precise, reliable heat treatment. Our solutions help you control the variables that lead to the common disadvantages of hardening.

Let our experts help you select the right equipment to:

- Achieve uniform heating and controlled quenching to reduce warping.

- Maintain surface integrity with controlled atmosphere options.

- Ensure repeatable results batch after batch.

Contact us today to discuss your laboratory's hardening needs and find a solution that enhances your material's properties without the drawbacks.

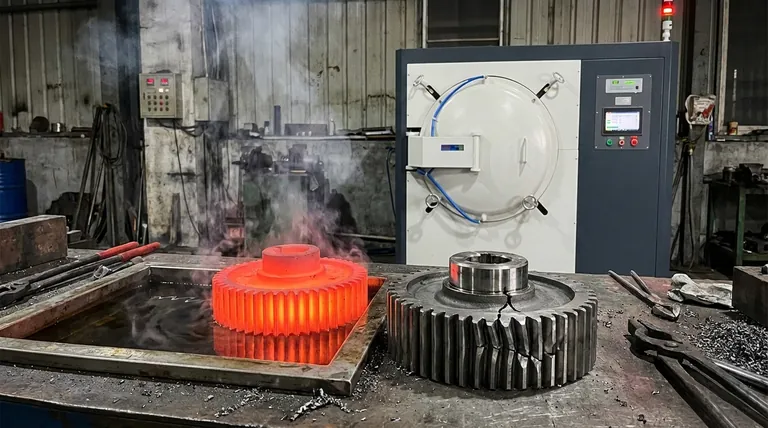

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the highest temperature for sintering? The Answer Depends on Your Material

- What is one common use for an incubator in a lab? Cultivate Microbiological Cultures for Accurate Analysis

- What elements can be detected by XRF? From Sodium to Uranium with a Critical Blind Spot

- How are industrial furnaces heated? Fuel vs. Electric for Optimal Performance

- Why is biomass better than coal? A Sustainable, Low-Carbon Energy Alternative

- What is sputtering yield? Master the Key to Efficient Thin Film Deposition

- What temperature is maintained in a bacterial incubator? The 37°C Standard Explained

- What is the difference between IR and FTIR? Discover the Superior Modern Spectroscopy Technique