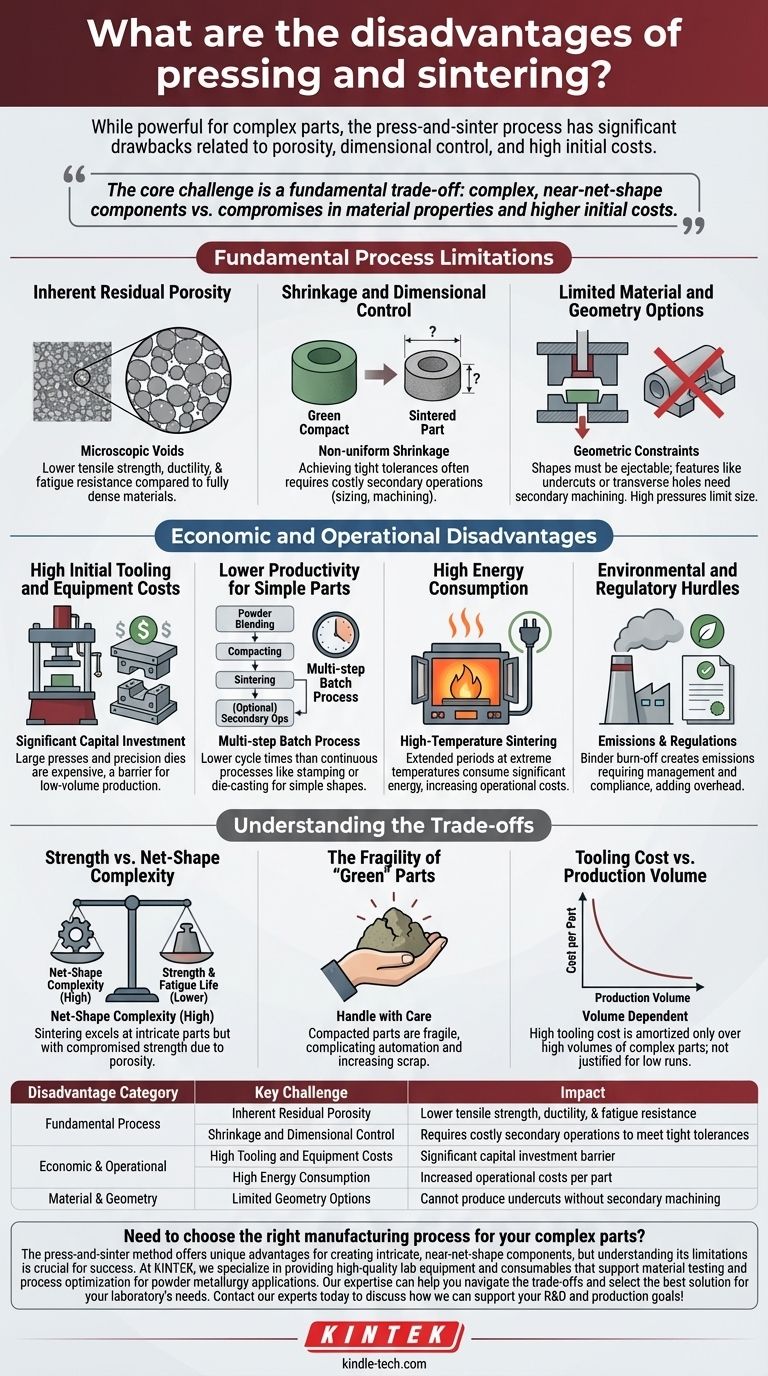

While a powerful method for creating complex parts, the press-and-sinter process is not without significant drawbacks. The primary disadvantages stem from the fundamental nature of the process, leading to inherent porosity that can limit mechanical performance, challenges in dimensional control, and high initial costs for tooling and equipment. Furthermore, the high-temperature sintering stage introduces operational complexities, including high energy consumption and potential environmental concerns.

The core challenge of pressing and sintering lies in a fundamental trade-off: you gain the ability to produce complex, near-net-shape components from a wide range of materials, but you must accept compromises in material properties and navigate higher initial costs compared to other manufacturing methods.

Fundamental Process Limitations

The most significant disadvantages are directly tied to the physics of consolidating and fusing powdered metal. These are not flaws that can be easily engineered out but are inherent characteristics of the process.

Inherent Residual Porosity

The sintering process works by heating a compressed powder "green" compact, causing the particles to diffuse and bond together. While this drastically increases density, it rarely eliminates all the microscopic voids between the original particles.

This residual porosity is the primary source of compromised mechanical properties. Compared to a fully dense material made by melting (casting) or forging, a sintered part will typically exhibit lower tensile strength, ductility, and fatigue resistance.

Shrinkage and Dimensional Control

During sintering, the part shrinks as its density increases. This shrinkage can be substantial and is not always perfectly uniform across the component's geometry.

Predicting and controlling this shrinkage to achieve tight dimensional tolerances is a significant engineering challenge. This often necessitates expensive secondary operations like sizing, coining, or machining to meet final specifications, adding cost and complexity to the workflow.

Limited Material and Geometry Options

While powder metallurgy supports a wide range of materials, the "press-and-sinter" method is constrained by the need to compact the powder in a rigid die.

This limits part geometry to shapes that can be ejected from the die, making features like undercuts or transverse holes impossible without secondary machining. Furthermore, the high pressures required limit the practical size and cross-sectional area of components.

Economic and Operational Disadvantages

Beyond the physics of the material, the economics and operational realities of running a press-and-sinter line present another set of challenges.

High Initial Tooling and Equipment Costs

The process requires a significant capital investment. Mechanical or hydraulic presses are large, expensive machines, and the hardened steel dies and punches required to form the parts are costly to manufacture and maintain. This high initial investment can be a barrier to entry, especially for low-volume production.

Lower Productivity for Simple Parts

Pressing and sintering is a multi-step batch process: powder blending, compacting, sintering, and potential secondary operations. When compared to continuous processes like stamping or die-casting for simpler shapes, its overall productivity and cycle times can be much lower.

High Energy Consumption

The sintering furnaces must operate at extremely high temperatures for extended periods, consuming a significant amount of energy. This directly translates to higher operational costs per part.

Environmental and Regulatory Hurdles

The high-temperature process can create environmental challenges. Burning off the binders mixed with the powder during the initial heating stage can release emissions that require careful management. These environmental factors and the associated governmental regulations can impact production rates and add operational overhead.

Understanding the Trade-offs

Choosing a manufacturing process is about balancing competing priorities. The disadvantages of sintering are best understood as trade-offs.

Strength vs. Net-Shape Complexity

The primary trade-off is performance versus complexity. Sintering excels at producing intricate, net-shape parts that would be prohibitively expensive or impossible to machine from a solid block. In return, you accept lower strength and fatigue life due to inherent porosity.

The Fragility of "Green" Parts

Before sintering, the compacted powder part (the "green" compact) is held together only by mechanical interlocking and binders. These parts are very fragile and must be handled with extreme care, which can complicate automation and increase scrap rates.

Tooling Cost vs. Production Volume

While tooling is expensive, for very high volumes of small, complex parts, the cost per part can become highly competitive because secondary machining is minimized or eliminated. For low-volume runs or simple shapes, the tooling cost is rarely justified.

Making the Right Choice for Your Goal

To select the correct process, you must first define your most critical objective.

- If your primary focus is maximum mechanical strength and fatigue life: Consider machining from wrought bar stock, forging, or metal injection molding (MIM) with hot isostatic pressing (HIP), as these methods produce fully dense parts.

- If your primary focus is low-cost mass production of simple shapes: Stamping (for sheet metal) or die casting (for non-ferrous metals) are almost always faster and more economical.

- If your primary focus is creating complex, net-shape parts from high-performance or difficult-to-machine materials: Pressing and sintering is an excellent candidate, provided you can design the component to accommodate its inherent performance limitations.

By understanding these constraints, you can accurately determine if powder metallurgy offers the optimal balance of cost, performance, and scalability for your project.

Summary Table:

| Disadvantage Category | Key Challenge | Impact |

|---|---|---|

| Fundamental Process | Inherent Residual Porosity | Lower tensile strength, ductility, and fatigue resistance |

| Fundamental Process | Shrinkage and Dimensional Control | Requires costly secondary operations to meet tight tolerances |

| Economic & Operational | High Tooling and Equipment Costs | Significant capital investment barrier |

| Economic & Operational | High Energy Consumption | Increased operational costs per part |

| Material & Geometry | Limited Geometry Options | Cannot produce undercuts or transverse holes without secondary machining |

Need to choose the right manufacturing process for your complex parts? The press-and-sinter method offers unique advantages for creating intricate, near-net-shape components, but understanding its limitations is crucial for success. At KINTEK, we specialize in providing high-quality lab equipment and consumables that support material testing and process optimization for powder metallurgy applications. Our expertise can help you navigate the trade-offs and select the best solution for your laboratory's needs. Contact our experts today to discuss how we can support your R&D and production goals!

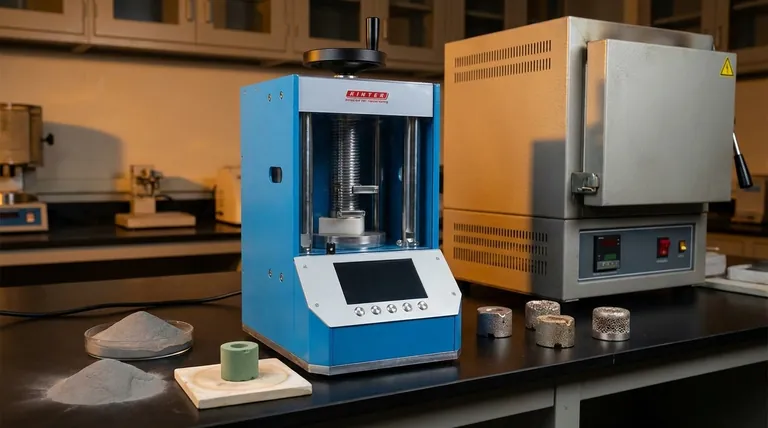

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- Why is a heated hydraulic press used for warm pressing NASICON green tapes? Optimize Your Solid Electrolyte Density

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What is the function of a laboratory hydraulic hot press in the assembly of solid-state photoelectrochemical cells?

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density