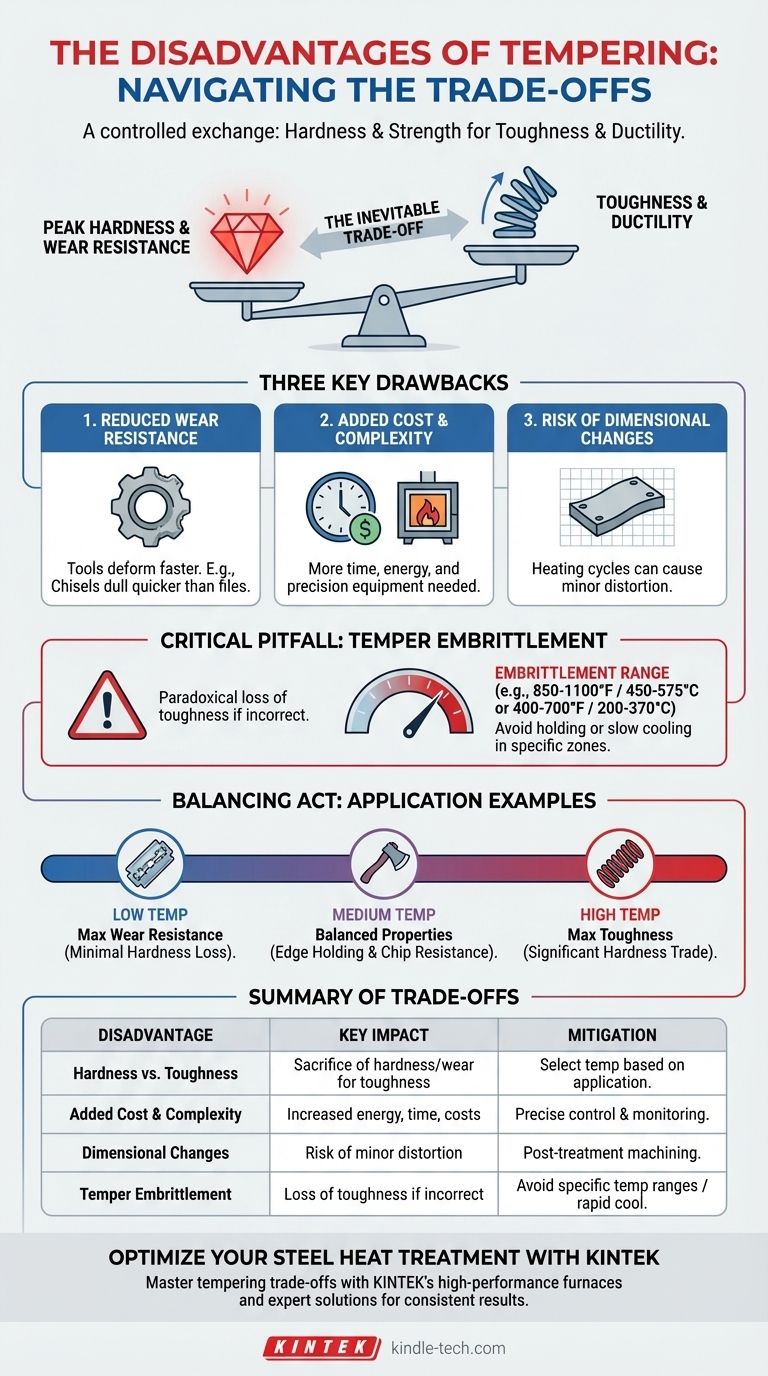

While an essential step for toughening steel, the tempering process is not without its costs. Its primary disadvantage is the direct and unavoidable trade-off between hardness and toughness. By tempering a hardened steel to reduce its brittleness, you simultaneously reduce its peak hardness, wear resistance, and tensile strength.

The core challenge in metallurgy is that you cannot maximize all properties at once. The main "disadvantage" of tempering is a necessary sacrifice: you intentionally give up a degree of hardness and strength in order to gain the critical properties of toughness and ductility.

The Fundamental Trade-off: Hardness vs. Toughness

To understand the disadvantages of tempering, you must first understand the state of the steel before the process begins. The entire point of heat treatment is a controlled exchange of properties.

The Purpose of Quenching: Achieving Maximum Hardness

Quenching—the rapid cooling of steel from a high temperature—is done for one reason: to create a microstructure called martensite.

Martensite is extremely hard and brittle. This state offers maximum wear resistance but is often too fragile for practical use, as it can shatter under impact or stress.

The Role of Tempering: Reclaiming Toughness

Tempering is the corrective process. By reheating the quenched steel to a specific temperature below its transformation point, you allow some of the trapped carbon atoms in the martensite structure to precipitate out.

This structural change relieves internal stresses and dramatically increases the steel's toughness (its ability to absorb energy and deform without fracturing) and ductility.

The Inevitable Consequence: Reduced Hardness and Strength

This gain in toughness comes at a direct cost. The same structural change that increases toughness also reduces the steel's hardness and tensile strength.

The higher the tempering temperature, the more toughness you gain, but the more hardness you lose. This is not a flaw in the process but its defining characteristic. The "disadvantage" is baked into the physics of the material.

Understanding the Key Drawbacks

Beyond the core trade-off, tempering introduces practical challenges and risks that must be managed in any manufacturing or engineering context.

1. Reduction in Wear Resistance

The most direct consequence of reduced hardness is a decrease in wear resistance.

A tool tempered for high toughness, like a chisel, will have its edge deform or dull more quickly than a tool tempered for high hardness, like a file.

2. Added Cost and Process Complexity

Tempering is an additional manufacturing step. It requires energy for the furnace, time for the part to heat and cool, and capital investment in precisely controlled ovens.

This adds both cost and another potential point of failure to the production line. A mistake in temperature or timing can ruin the part.

3. Risk of Dimensional Changes

While tempering relieves the major internal stresses from quenching, the heating and cooling cycle can still cause minor distortion or dimensional changes in the part.

For high-precision components, these small changes must be anticipated and potentially corrected with post-treatment grinding or machining.

A Critical Pitfall: Temper Embrittlement

Paradoxically, tempering can sometimes make steel more brittle if performed incorrectly. This phenomenon, known as temper embrittlement, is a critical disadvantage to avoid.

What Is Temper Embrittlement?

Temper embrittlement is a loss of toughness that occurs when steel is held within, or cooled slowly through, a specific temperature range.

This is a counter-intuitive and dangerous outcome, as the goal of tempering is precisely the opposite. It primarily affects certain alloy steels.

The Embrittlement Range

The most common form occurs in a range of approximately 850-1100°F (450-575°C). Holding the steel in this range or cooling it slowly through this zone can cause impurities to segregate at grain boundaries, weakening the material.

Another form, "blue brittleness," can occur at lower temperatures around 400-700°F (200-370°C), causing a drop in toughness.

How to Avoid It

Engineers avoid this by carefully controlling the tempering parameters. The primary strategies are to either temper below or above the embrittlement range, or to cool the steel rapidly after tempering at higher temperatures.

Making the Right Choice for Your Goal

The "disadvantages" of tempering are simply variables to be controlled. The key is to choose a tempering temperature that achieves the ideal balance of properties for the component's final application.

- If your primary focus is maximum wear resistance and edge retention (e.g., a razor blade, file, or lathe tool): You will use a very low tempering temperature (e.g., 300-400°F / 150-200°C) to sacrifice minimal hardness.

- If your primary focus is maximum toughness and shock resistance (e.g., a spring, hammer, or sword): You will use a high tempering temperature (e.g., 800-1100°F / 425-600°C) to trade significant hardness for superior ductility.

- If your primary focus is a balance of hardness and toughness (e.g., an axe, chisel, or general-purpose knife): You will select a medium tempering temperature that provides a functional compromise between edge holding and chip resistance.

Understanding these trade-offs is what transforms tempering from a simple recipe into a powerful engineering tool.

Summary Table:

| Disadvantage | Key Impact | Mitigation/Consideration |

|---|---|---|

| Hardness vs. Toughness Trade-off | Sacrifice of hardness/wear resistance for increased toughness | Select tempering temperature based on application requirements |

| Added Cost & Complexity | Increased energy, time, and equipment costs | Requires precise temperature control and process monitoring |

| Dimensional Changes | Risk of minor distortion or warping | May require post-treatment machining for precision parts |

| Temper Embrittlement | Loss of toughness if performed incorrectly | Avoid specific temperature ranges or use rapid cooling |

Optimize Your Steel Heat Treatment with KINTEK

Navigating the complexities of tempering requires precision equipment and expert knowledge. At KINTEK, we specialize in high-performance lab furnaces and consumables designed for exacting heat treatment processes. Our solutions help you achieve the perfect balance of hardness and toughness while minimizing risks like distortion and embrittlement.

Whether you're working on tools, springs, or precision components, KINTEK provides the reliable equipment and support you need to master the tempering trade-offs.

Contact our experts today to discuss how our lab equipment can enhance your steel treatment processes and deliver consistent, high-quality results.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a final heat treatment at 1273 K required for ODS high-entropy alloys? Ensure Accurate Testing Results

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- What is the safety of a muffle furnace? Ensuring Secure Operation with Modern Design and Protocols

- What is the purpose of high-temperature muffle furnaces and ceramic crucibles? Master NREL Ash Analysis

- What role does a muffle furnace play in assessing biomass fuel? Ensure Precise Inorganic Analysis & Fuel Quality

- Why must LAGP glass melts be immediately placed in a heating furnace for annealing at 500°C after quenching?

- Why is a microcomputer furnace critical for isothermal graphite oxidation? Achieve Precise ±0.5 K Thermal Stability

- What is ashing in mineral analysis? Key Steps for Accurate Elemental Analysis