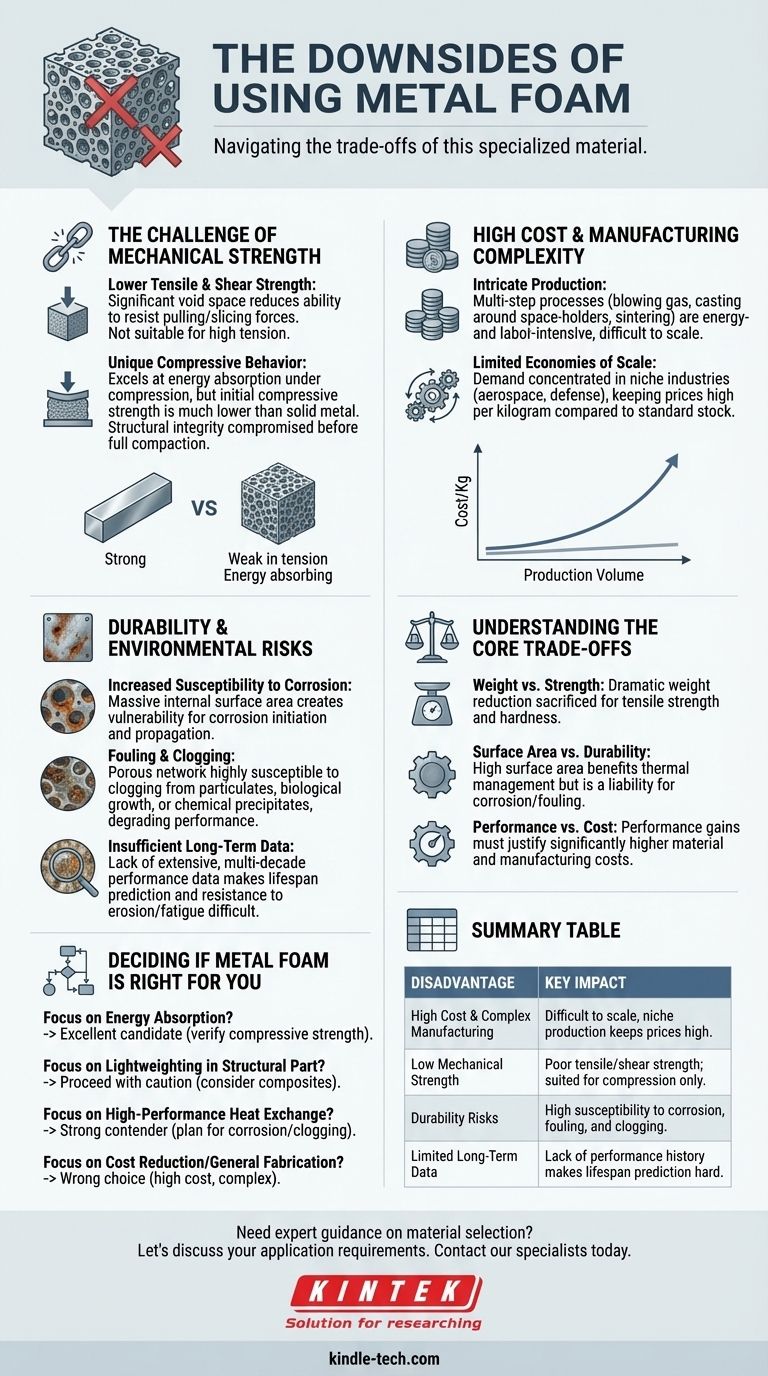

While offering a unique combination of properties, metal foam is not a universal solution. Its primary disadvantages are a direct result of its porous, cellular structure: high manufacturing costs, significantly lower mechanical strength compared to solid metals, and a lack of comprehensive data on its long-term durability in real-world conditions.

The core challenge of using metal foam lies in its nature as a specialist material. Its unique benefits, like low weight and high surface area, are intrinsically linked to its greatest weaknesses—cost, strength, and predictable long-term performance.

The Challenge of Mechanical Strength

Metal foam's primary purpose is often to be lightweight, but this comes at the direct expense of mechanical robustness compared to a solid piece of the same parent metal.

Lower Tensile and Shear Strength

Because the material is mostly void space, its ability to resist pulling (tensile) or slicing (shear) forces is dramatically reduced. It is not suitable for applications where it will be under significant tension.

Compressive Behavior is Unique, Not Always Superior

Metal foam excels at absorbing energy under compression, crushing at a near-constant stress level. However, its initial compressive strength is far lower than its solid counterpart. Once fully compacted, it behaves like a solid metal, but its primary structural integrity is compromised long before that point.

High Cost and Manufacturing Complexity

The production of metal foam is a complex, multi-step process that is difficult to scale, making it significantly more expensive than standard metal stock.

Intricate Production Methods

Processes involve either blowing gas into molten metal, casting metal around removable space-holders, or sintering metal powders. These methods require precise control and are far more energy- and labor-intensive than simply casting a solid ingot.

Limited Economies of Scale

Unlike sheet metal or bar stock, the demand for metal foam is concentrated in niche, high-value industries like aerospace and defense. This limits the potential for mass production to drive down costs, keeping the price per kilogram high.

Durability and Environmental Risks

The vast internal surface area that makes metal foam excellent for heat exchange also makes it highly vulnerable to environmental degradation.

Increased Susceptibility to Corrosion

Every internal pore and strut massively increases the surface area exposed to the environment. For a given volume, a metal foam part can have thousands of times more surface area than a solid part, creating a huge vulnerability for corrosion to initiate and propagate.

The Problem of Fouling and Clogging

In applications involving fluid flow, such as heat exchangers or filters, the intricate network of pores is highly susceptible to fouling. Particulates, biological growth, or chemical precipitates can easily clog the foam, degrading performance or causing complete failure.

Insufficient Long-Term Data

As a relatively niche material, there is a lack of extensive, decades-long performance data across a wide range of environments. This makes it difficult to accurately predict its lifespan and resistance to factors like long-term erosion from fluid flow or cyclic fatigue.

Understanding the Core Trade-offs

Choosing metal foam requires a clear-eyed assessment of its inherent compromises. Its advantages and disadvantages are two sides of the same coin.

Weight vs. Strength

This is the most fundamental trade-off. You achieve dramatic weight reduction but sacrifice tensile strength, shear strength, and hardness. The material is best suited for compression-dominated loads where energy absorption is the primary goal.

Surface Area vs. Durability

The high surface area is a major benefit for thermal management and chemical catalysis. However, this same feature is a major liability for corrosion and fouling. Using it in harsh environments requires careful material selection (e.g., using corrosion-resistant alloys) and system design to mitigate these risks.

Performance vs. Cost

The final decision often comes down to budget. The performance gains from metal foam—such as impact absorption or heat dissipation—must be significant enough to justify a material cost that can be an order of magnitude higher than that of its solid equivalent.

Deciding if Metal Foam is Right for Your Application

Use these guidelines to determine if metal foam's downsides are acceptable for your project's goals.

- If your primary focus is energy absorption: Metal foam is an excellent candidate, provided you have verified its compressive strength meets the demands of the expected impact.

- If your primary focus is maximum lightweighting in a structural part: You should proceed with extreme caution and consider alternatives like carbon fiber composites, as the foam's low tensile strength is a major liability.

- If your primary focus is high-performance heat exchange: The material is a strong contender, but your design must include plans for managing potential corrosion and mitigating the risk of clogging.

- If your primary focus is cost reduction or general fabrication: Metal foam is almost certainly the wrong choice due to its high material cost and specialized manufacturing requirements.

By carefully weighing these limitations against its unique benefits, you can determine if metal foam is a strategic advantage or an unnecessary complication for your project.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Cost & Complex Manufacturing | Difficult to scale, niche production keeps prices high. |

| Low Mechanical Strength | Poor tensile/shear strength; suited for compression only. |

| Durability Risks | High susceptibility to corrosion, fouling, and clogging. |

| Limited Long-Term Data | Lack of performance history makes lifespan prediction hard. |

Need expert guidance on material selection for your lab or project?

Choosing the right material is critical for success. At KINTEK, we specialize in providing high-quality lab equipment and consumables, helping researchers and engineers navigate complex material decisions. Whether you're working with advanced materials like metal foam or need reliable standard equipment, our expertise ensures you get the performance and durability your work demands.

Let's discuss your specific application requirements. Contact our specialists today to find the perfect solution for your laboratory needs.

Visual Guide

Related Products

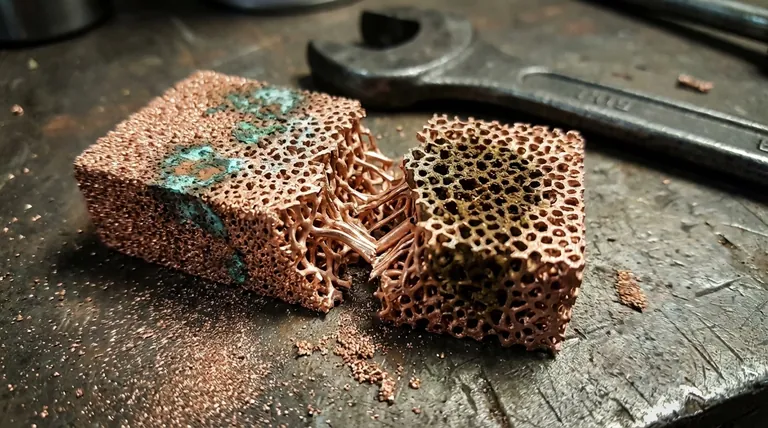

- Copper Foam

- Copper Nickel Foam Metal Sheet

- High Purity Gold Platinum Copper Iron Metal Sheets

- High Purity Zinc Foil for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the common applications of copper foam? A Guide to Its High-Performance Uses

- Is copper foam safe? Discover the facts about its antimicrobial and cooling benefits

- What are the characteristics of copper foam? Unlock High-Performance Thermal and Electrical Solutions

- What is nickel foam used for? A Guide to Its Electrochemical Applications

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- How do you transfer graphene from copper? A Step-by-Step Guide to Preserving Pristine Quality

- What is copper foam used for? A Guide to Its High-Performance Thermal and Energy Applications

- How to make nickel foam? A Guide to the Templating and Electroplating Process