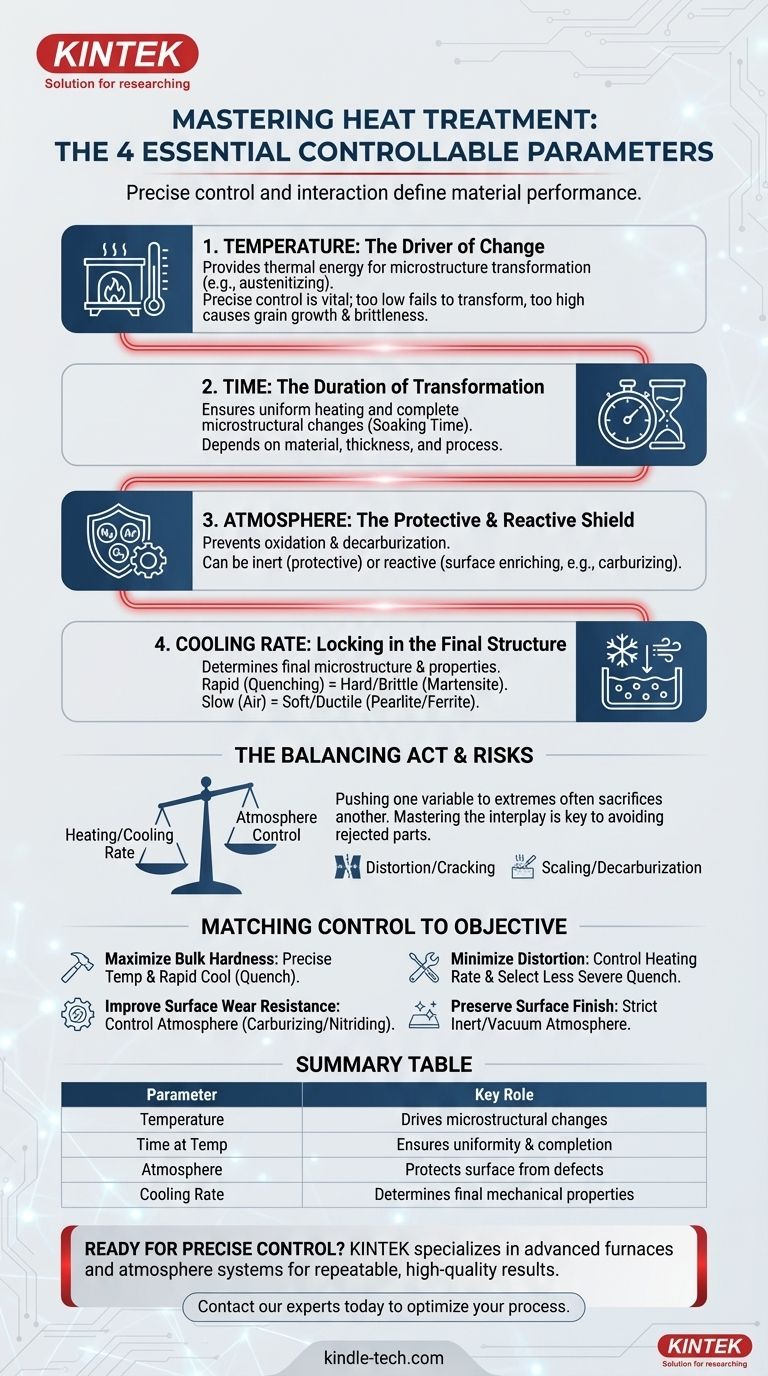

At its core, controlling a heat treatment process hinges on the deliberate manipulation of four fundamental parameters. The essential controllable parameters in any heat treatment are temperature, time at temperature, the surrounding atmosphere, and the cooling rate. These four variables work in concert to fundamentally alter a material's microstructure, which in turn dictates its final mechanical properties like hardness, strength, and wear resistance.

The ultimate goal is not merely to control these parameters in isolation, but to master their interaction. True process control means understanding how this interplay transforms a raw material into a component with precise, repeatable, and predictable performance characteristics.

The Four Pillars of Heat Treatment Control

To achieve a desired outcome, you must have independent and precise control over each of the four core variables. Each one plays a distinct and critical role in the final transformation of the material.

Temperature: The Driver of Change

Temperature provides the necessary thermal energy to initiate changes in the material's crystal structure (microstructure). For steels, this often means heating above a critical transformation temperature (the austenitizing temperature) to create a uniform starting structure.

Precise temperature control is non-negotiable. Too low, and the desired transformation won't occur; too high, and you risk undesirable effects like grain growth, which can make the material brittle.

Time: The Duration of Transformation

Once the target temperature is reached, the material is held there for a specific duration, often called the soaking time. This ensures two things: the temperature becomes uniform throughout the entire part, and the microstructural transformations have sufficient time to complete.

The required time depends heavily on the material's composition, the part's cross-sectional thickness, and the specific process being performed.

Atmosphere: The Protective and Reactive Shield

The atmosphere inside the furnace is a critical but often overlooked parameter. Its primary role can be either protective or reactive. An uncontrolled atmosphere (like open air) will cause oxidation (scaling) and decarburization (loss of carbon from the surface), damaging the part.

A controllable atmosphere, as noted in the references, prevents these issues. It can be inert (like nitrogen or argon) to simply protect the surface, or it can be a carefully formulated mixture of gases designed to actively change the surface chemistry, such as in carburizing processes that add carbon to increase surface hardness.

Cooling Rate: Locking in the Final Structure

The rate at which a part is cooled from its treatment temperature determines its final microstructure and, therefore, its properties. This is perhaps the most dramatic stage of the process.

A very rapid cool, known as quenching (in oil, water, or polymer), can trap the material in a hard, brittle state (martensite). A slow cool, such as in still air, will result in a much softer, more ductile structure (pearlite or ferrite).

Understanding the Trade-offs and Risks

Controlling these parameters is a balancing act. Pushing one variable to its extreme to maximize a single property often comes at the expense of another and introduces significant risks.

The Risk of Poor Atmospheric Control

Failing to control the furnace atmosphere is a direct path to rejected parts. Unwanted reactions with air lead to scaling, which ruins surface finish and dimensional accuracy, and decarburization, which creates a soft surface layer that drastically reduces wear resistance and fatigue strength.

Achieving precise control of the surface carbon content is a key advantage of modern heat treatment, directly improving the component's performance and service life.

The Balancing Act of Heating and Cooling

Heating a part too quickly can induce thermal stress, leading to distortion or even cracking before it ever reaches the quenching stage.

Likewise, the quenching process itself is a major source of risk. While a faster quench produces greater hardness, it also creates immense internal stresses that can cause a part to warp, distort, or crack, especially in complex geometries.

Matching Control to Your Objective

Your strategy for controlling these four parameters should be dictated entirely by your end goal for the component.

- If your primary focus is maximizing bulk hardness: You will need precise temperature control above the critical point, followed by a carefully selected rapid cooling rate (quenching).

- If your primary focus is improving surface wear resistance: You must focus on controlling the furnace atmosphere for processes like carburizing or nitriding to enrich the surface chemistry.

- If your primary focus is minimizing distortion: Your control over the heating rate and, most critically, the cooling rate (often by selecting a less severe quenching medium) will be paramount.

- If your primary focus is preserving surface finish: Strict control of the furnace atmosphere to create an inert or vacuum environment is your key to preventing oxidation and decarburization.

By deliberately manipulating these four parameters, you move from simply heating metal to engineering its final performance with precision.

Summary Table:

| Parameter | Key Role in Heat Treatment |

|---|---|

| Temperature | Drives microstructural changes; must be precise to avoid defects. |

| Time at Temperature | Ensures uniform heating and complete transformation. |

| Atmosphere | Protects the surface from oxidation and decarburization. |

| Cooling Rate | Determines the final hardness, strength, and ductility. |

Ready to achieve precise control over your heat treatment processes? KINTEK specializes in advanced laboratory furnaces and atmosphere control systems that deliver the exact temperature, time, atmosphere, and cooling profiles you need. Whether your goal is maximizing hardness, improving surface wear resistance, or minimizing distortion, our equipment ensures repeatable, high-quality results.

Contact our experts today to discuss how we can help you optimize your heat treatment for superior material performance.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What is the purpose of using an atmosphere-controlled heating furnace for Cu reduction? Achieve Active Catalytic States

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- Can nitrogen be used for brazing? Key Conditions and Applications Explained