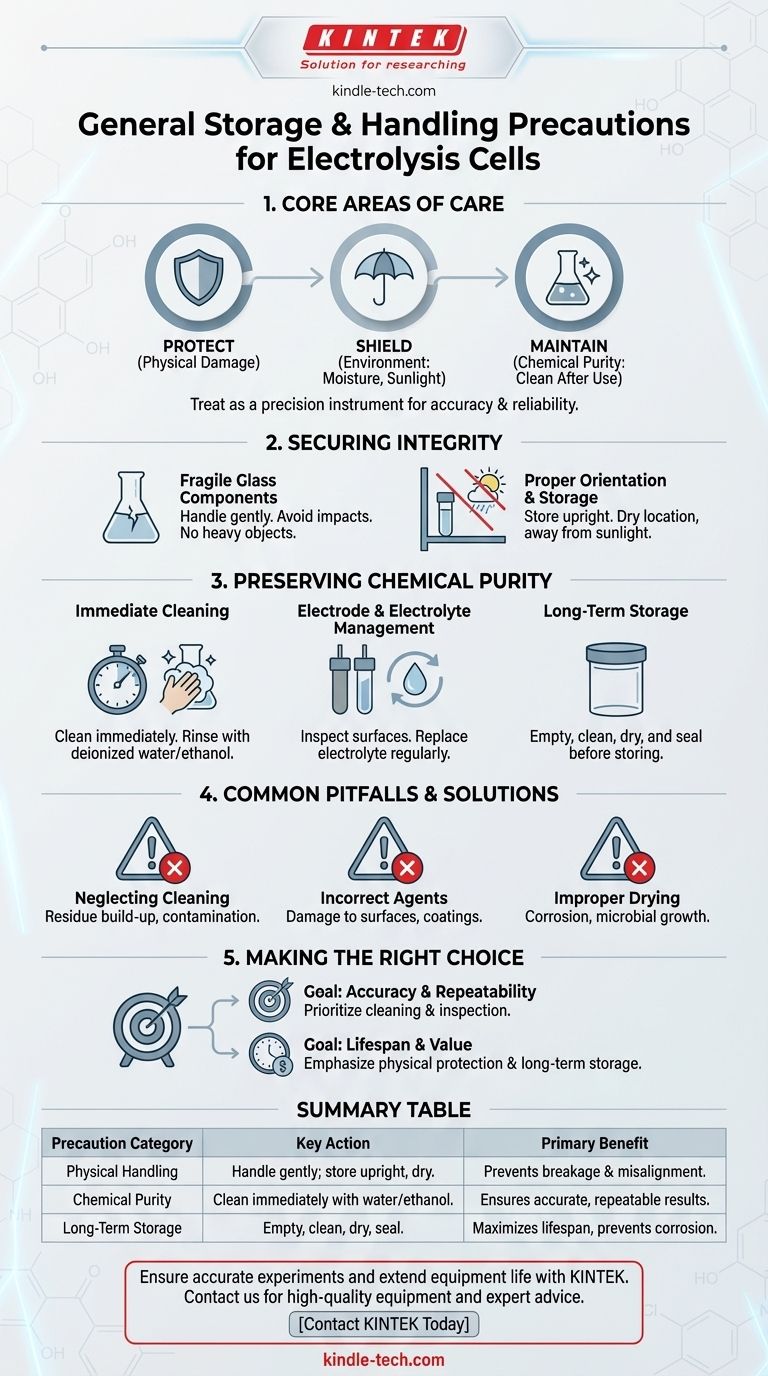

To properly care for an electrolysis cell, you must focus on three core areas: protecting it from physical damage, shielding it from environmental factors like moisture and sunlight, and maintaining its chemical purity through diligent cleaning after every use. It should always be stored upright in a dry location, handled gently due to its fragile glass construction, and cleaned immediately after an experiment to prevent residue buildup.

The core principle of electrolysis cell care is treating it not as a simple piece of glassware, but as a precision instrument. Proper handling and cleaning are not just for preventing breakage, but for preserving the chemical integrity of the system to ensure accurate and repeatable experimental results.

Securing Physical and Environmental Integrity

Proper storage and handling are the first line of defense in protecting your investment and ensuring the cell's basic functionality.

The Fragility of Glass Components

The primary body of most electrolysis cells is made of glass. This material is ideal for its chemical inertness but makes the device inherently fragile.

You must handle the cell gently and cautiously at all times. Avoid any impacts or setting it down hard, as even minor shocks can create micro-fractures that compromise its structural integrity over time.

Never place heavy objects on top of the cell, as this can easily cause it to crack or break.

Maintaining Proper Orientation and Storage

The cell must be stored in an upright position. This orientation prevents any residual electrolyte from spilling and ensures internal components, like electrodes, remain properly aligned and secure.

For storage, choose a location that is dry and protected from direct sunlight. Moisture can lead to corrosion of metallic components and connections, while prolonged UV exposure can degrade certain materials or sensitive electrolytes.

Preserving Chemical Purity for Accurate Results

Physical safety is only half the battle. The performance of an electrolysis cell is dictated by its chemical cleanliness. Contamination is the primary cause of inaccurate or failed experiments.

The Critical Need for Immediate Cleaning

Residue from a previous experiment can poison catalysts, alter electrolyte conductivity, or introduce unintended side reactions. For this reason, you must clean the vessel and electrodes immediately after each use.

Start by rinsing with deionized water or ethanol. If stubborn residue remains, a dilute acid or alkali treatment may be necessary, but always verify compatibility with your cell's specific materials first.

Electrode and Electrolyte Management

The electrodes are the heart of the cell. Regularly inspect their surfaces for any signs of physical damage, pitting, or contamination that could impede performance.

Do not leave electrodes in prolonged contact with air, water, or other substances that could cause oxidation or degradation. Likewise, the electrolyte should be replaced regularly based on usage to prevent the accumulation of impurities that skew results.

Preparing for Long-Term Storage

If the cell will not be used for an extended period, you must take extra steps.

Completely empty the electrolyte from the vessel. After thoroughly cleaning and drying all components, store the equipment in a dry environment, ideally sealed to protect it from dust and atmospheric moisture.

Common Pitfalls and How to Avoid Them

Even with the best intentions, simple mistakes can compromise your equipment. Being aware of these common pitfalls is crucial for long-term reliability.

Neglecting Post-Experiment Cleaning

This is the single most common cause of performance degradation. The convenience of "cleaning it later" often leads to hardened residues that are difficult to remove and can permanently contaminate the cell.

Using Incorrect Cleaning Agents

Aggressive or inappropriate chemicals can do more harm than good. Abrasive cleaners can scratch glass, while strong, unapproved solvents can etch surfaces or damage electrode coatings. Always start with the mildest effective solvent.

Improper Drying or Storage

Putting the cell away while still damp invites corrosion and can allow microbial growth. Likewise, storing it unsealed in a non-dry environment negates the effort of cleaning and can lead to contamination before its next use.

Making the Right Choice for Your Goal

Your maintenance protocol should align with your primary objective.

- If your primary focus is experimental accuracy and repeatability: Prioritize immediate and thorough post-experiment cleaning and regular inspection of the electrodes and electrolyte.

- If your primary focus is maximizing equipment lifespan and value: Emphasize careful physical handling, protection from environmental factors, and proper long-term storage procedures like emptying the electrolyte.

Ultimately, consistent and thoughtful care is what ensures your electrolysis cell remains a reliable and precise scientific tool.

Summary Table:

| Precaution Category | Key Action | Primary Benefit |

|---|---|---|

| Physical Handling | Handle gently; store upright in a dry place. | Prevents breakage and component misalignment. |

| Chemical Purity | Clean immediately after use with deionized water/ethanol. | Ensures accurate, repeatable experimental results. |

| Long-Term Storage | Empty electrolyte; clean and dry thoroughly before sealing. | Maximizes equipment lifespan and prevents corrosion. |

Ensure your lab's electrolysis experiments are accurate and your equipment lasts longer. Proper care is essential for reliable results. The experts at KINTEK specialize in providing high-quality lab equipment and consumables, along with the expert advice needed to maintain them. Let us help you protect your investment and achieve superior performance.

Contact KINTEK today for personalized support and solutions tailored to your laboratory's needs.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments