While a robust and cost-effective method for certain applications, compression molding is not a universal solution. Its primary limitations stem from slower production cycles, constraints on part complexity, and a higher degree of manual labor compared to processes like injection molding. These factors make it less suitable for high-volume manufacturing of intricate components.

Compression molding excels at producing large, strong, and relatively simple parts, particularly from thermoset plastics and composites. However, its inherent trade-offs in speed, precision, and geometric capability mean it is often outmatched by other methods for complex, high-volume production runs.

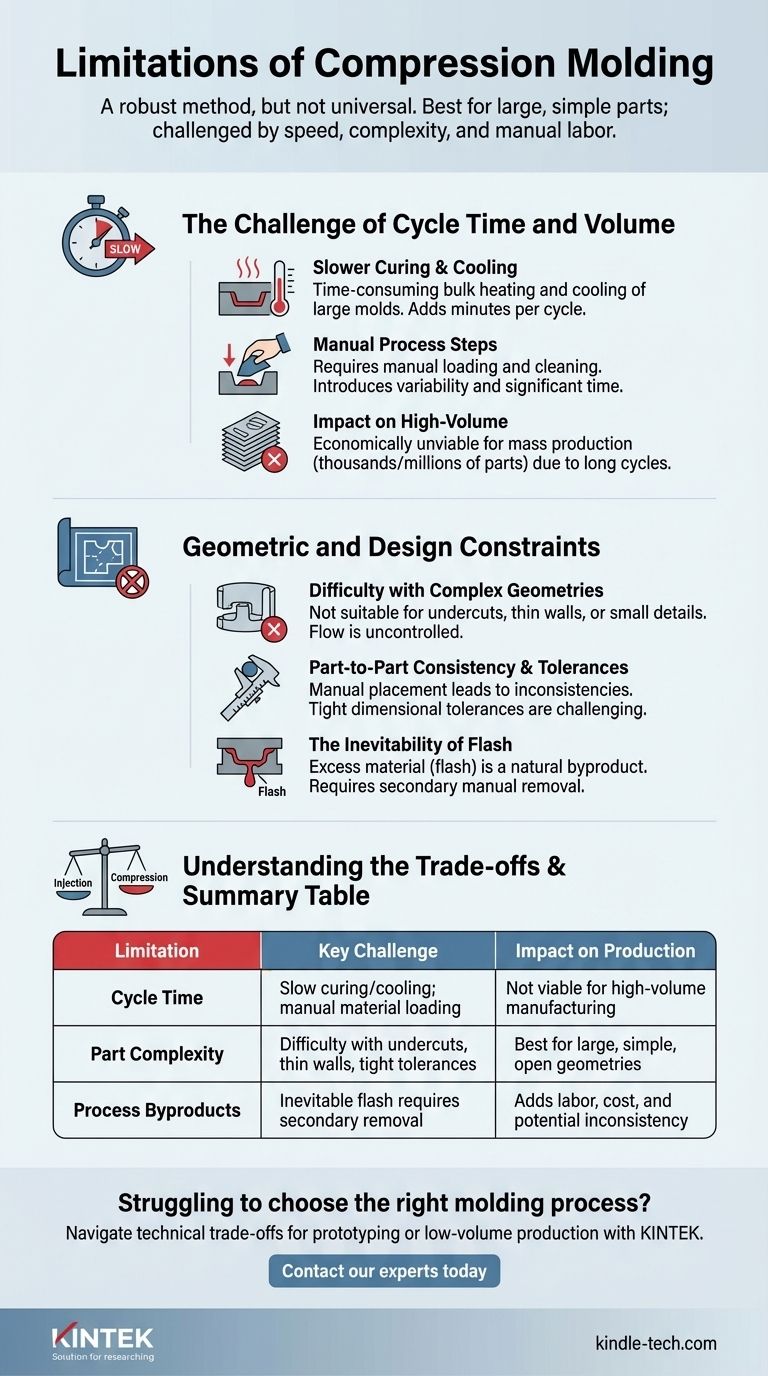

The Challenge of Cycle Time and Volume

One of the most significant constraints of compression molding is its speed. The total time required to produce a single part, known as the cycle time, is considerably longer than that of more automated processes.

Slower Curing and Cooling Cycles

The process involves heating the entire mold mass to cure the material and then often cooling it before the part can be ejected. This bulk heating and cooling is time-consuming, especially with the large, heavy steel molds required for producing substantial parts.

Unlike injection molding, where material is heated before entering a relatively cool mold, compression molding relies on thermal transfer through the mold itself, adding minutes to every cycle.

Manual Process Steps

Compression molding is often a semi-automatic or manual process. An operator must accurately measure and place the material charge (a preform or powder) into the mold cavity before every cycle.

After curing, the part is removed, and the mold must be cleaned of any residual material or flash before the next cycle can begin. These manual steps introduce variability and add significant time.

Impact on High-Volume Production

The combination of long cure times and manual intervention makes compression molding economically unviable for mass production, where thousands or millions of parts are needed quickly. Processes like injection molding are designed for high-speed, continuous, and automated operation, yielding a much lower cost-per-part at high volumes.

Geometric and Design Constraints

The fundamental nature of the process—pressing material into a shape—imposes clear limits on the types of parts that can be successfully manufactured.

Difficulty with Complex Geometries

Compression molding is best suited for parts with relatively simple, open geometries. The flow of the material under pressure is not as controlled as in injection molding.

Features like undercuts, thin walls, small holes, or intricate ribs are difficult or impossible to form reliably. The material may not flow into these fine details before it begins to cure, resulting in incomplete or weak parts.

Part-to-Part Consistency and Tolerances

Because the initial material charge is often placed by hand, slight variations in its position or amount can lead to inconsistencies from one part to the next.

This makes holding tight dimensional tolerances challenging. While sufficient for many applications like electrical enclosures or automotive body panels, it is not suitable for precision components where tolerances are measured in thousandths of an inch.

The Inevitability of Flash

When the mold closes, excess material is squeezed out from the cavity along the parting line. This excess, known as flash, is a natural byproduct of the process.

Flash must be removed in a secondary operation, typically by hand or with trimming dies. This adds labor, cost, and another potential source of inconsistency to the manufacturing workflow.

Understanding the Trade-offs

Choosing a manufacturing process is always about balancing competing priorities. The limitations of compression molding are best understood in contrast to its primary alternative, injection molding.

Compression vs. Injection Molding

Injection molding excels where compression molding falters: it can produce highly complex, tightly-toleranced parts at very high speeds. However, it requires extremely expensive and complex tooling.

Compression molding's advantage lies in its simpler, more robust, and significantly cheaper tooling. This makes it a cost-effective choice for low-to-medium volume production of large parts where tooling amortization is a major cost driver.

Material Suitability

Compression molding is exceptionally well-suited for thermoset materials (like phenolics, epoxies, and silicones) and fiber-reinforced composites (like SMC and BMC). The process allows long fibers to maintain their orientation and length, yielding parts with superior strength and stiffness that are difficult to achieve with injection molding.

Is Compression Molding Right for Your Project?

Answering this requires evaluating your project's specific goals for volume, complexity, material properties, and cost.

- If your primary focus is producing large, simple, high-strength parts: Compression molding is an excellent choice, especially for thermosets, composites, and applications in the automotive, aerospace, or electrical industries.

- If your primary focus is high-volume production of complex parts with tight tolerances: Injection molding is the clear and superior process for your needs.

- If your primary focus is minimizing initial tooling investment for low-to-medium volumes: Compression molding offers a significant cost advantage over injection molding, provided you can accommodate its slower cycle times and design constraints.

Ultimately, the limitations of compression molding are features, not bugs; they define the specific industrial niche where the process provides unmatched value.

Summary Table:

| Limitation | Key Challenge | Impact on Production |

|---|---|---|

| Cycle Time | Slow curing/cooling; manual material loading | Not viable for high-volume manufacturing |

| Part Complexity | Difficulty with undercuts, thin walls, tight tolerances | Best for large, simple, open geometries |

| Process Byproducts | Inevitable flash requires secondary removal | Adds labor, cost, and potential inconsistency |

Struggling to choose the right molding process for your lab or production needs?

The limitations of compression molding highlight the importance of selecting the correct equipment for your specific application, whether it's for prototyping, low-volume production, or working with specialized materials like thermoset composites.

At KINTEK, we specialize in providing robust lab equipment and consumables to support your research and manufacturing processes. We can help you navigate these technical trade-offs to find the optimal solution for your requirements.

Let's optimize your workflow together. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

People Also Ask

- How does a laboratory hydraulic press facilitate catalyst preparation? Perfecting Pellets for Industrial Testing

- What is the law behind the hydraulic press? Understanding Pascal's Law for Immense Force

- Why are high-precision laboratory hydraulic presses used for testing PHBV? Ensure Flawless Sample Preparation

- How much weight can a hydraulic press do? Understand Force vs. Weight for Safe Operation

- Where are hydraulic presses used? Powering Industries from Automotive to Aerospace

- What are the environmental impacts of a hydraulic press? Minimizing Energy and Fluid Footprints

- What is the role of a laboratory hydraulic press in the preparation of rare earth denitrification catalysts?

- How many tons can a hydraulic press do? From 5-Ton Benchtop Units to 75,000-Ton Industrial Giants