In vacuum deposition, the primary methods for depositing metal layers fall into two main families: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). PVD involves physically moving material from a source to a substrate through vaporization or sputtering, while CVD uses chemical reactions of precursor gases on the substrate's surface to form the film.

The core challenge is not simply knowing the names of these methods, but understanding their fundamental mechanisms. Your choice of method will directly dictate the film's properties, such as its density, adhesion, uniformity, and purity.

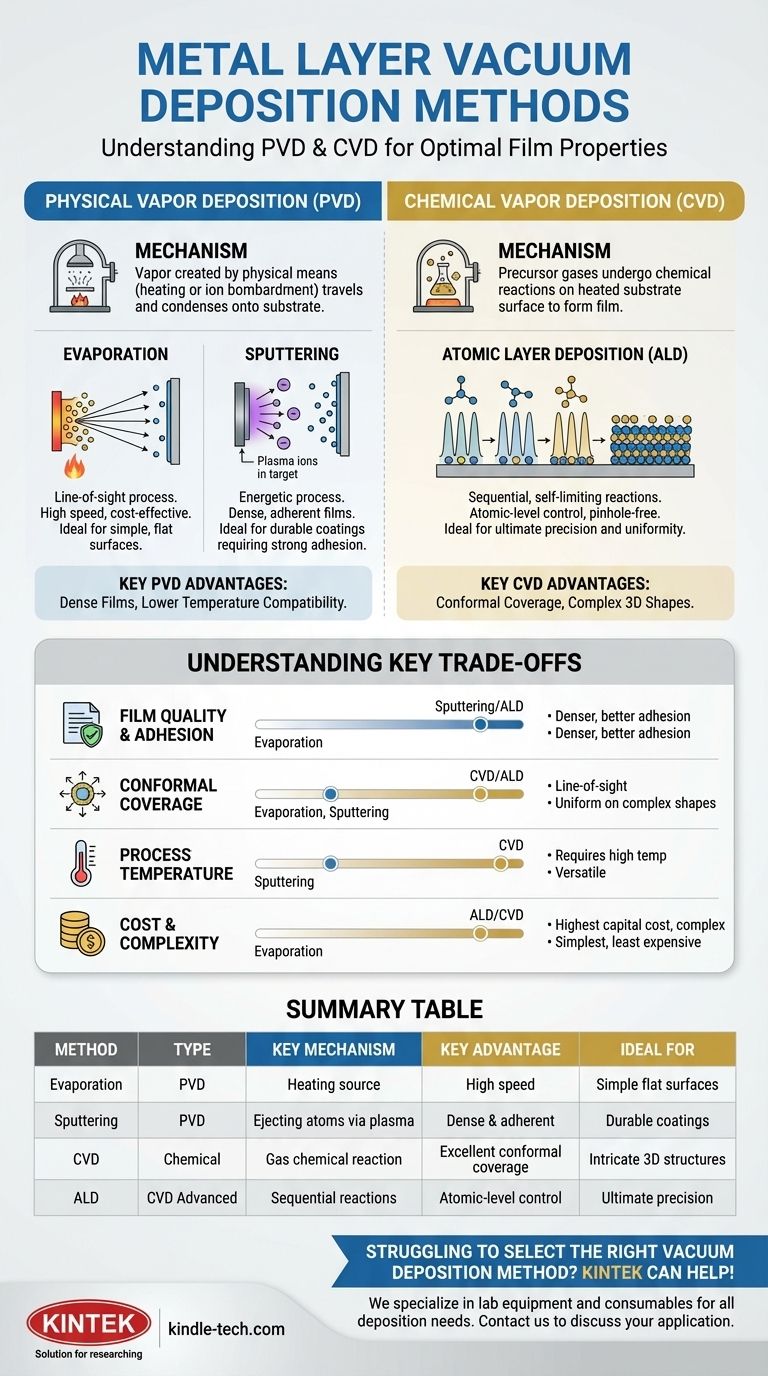

The Two Pillars of Deposition: PVD and CVD

Nearly all vacuum deposition techniques can be categorized as either a physical or chemical process. Understanding this distinction is the first step in selecting the right tool for the job.

Physical Vapor Deposition (PVD)

PVD techniques create a vapor of the source material through purely physical means—either by heating it or by bombarding it with energetic ions. This vapor then travels through the vacuum chamber and condenses onto the substrate, forming the thin film.

Evaporation

Evaporation is a straightforward, line-of-sight process. A source material, or "charge," is heated in a high vacuum until its atoms vaporize. These atoms travel in a straight line until they strike the cooler substrate and condense into a solid film. The most common variant is electron beam evaporation, where a high-energy electron beam is used to heat the source material with great precision.

Sputtering

Sputtering is a more energetic process. It begins by creating a plasma, typically from an inert gas like argon. Positively charged ions from this plasma are accelerated towards a "target" made of the desired coating material. The impact of these ions ejects, or "sputters," atoms from the target, which then deposit onto the substrate. Magnetron sputtering uses powerful magnets to confine the plasma near the target, dramatically increasing the deposition rate.

Chemical Vapor Deposition (CVD)

Unlike PVD, CVD does not start with a solid block of the coating material. Instead, one or more volatile precursor gases containing the required elements are introduced into the chamber. These gases decompose or react on the heated substrate's surface, leaving behind the desired solid film.

Atomic Layer Deposition (ALD)

ALD is a highly advanced subtype of CVD that offers unparalleled control over film thickness and conformality. It works by introducing precursor gases in sequential, self-limiting pulses. Each pulse creates exactly one atomic layer on the substrate, allowing for the growth of perfectly uniform, pinhole-free films with atomic-level precision.

Understanding the Key Trade-offs

No single method is universally superior. The optimal choice depends entirely on a balance of required film properties, substrate characteristics, and process cost.

Film Quality vs. Deposition Speed

Sputtered films are typically denser, more adherent, and have lower internal stress than evaporated films due to the higher energy of the depositing atoms. However, evaporation can be a faster process for certain materials. ALD produces the highest quality films but is by far the slowest method.

Conformal Coverage vs. Line-of-Sight

Because PVD processes like evaporation and sputtering are line-of-sight, they struggle to uniformly coat complex, three-dimensional surfaces, leading to "shadowing" effects. In contrast, CVD and ALD excel at creating highly conformal coatings that perfectly replicate the underlying topography.

Process Temperature and Substrate Compatibility

Traditional CVD often requires very high substrate temperatures to drive the necessary chemical reactions. This can damage sensitive substrates like polymers or certain electronic components. PVD methods, particularly sputtering, can often be performed at much lower temperatures, making them more versatile.

Cost and Complexity

Generally, evaporation systems are the simplest and least expensive. Sputtering systems are moderately complex, while CVD and especially ALD systems are the most complex and carry the highest capital cost due to the precise gas handling and process control required.

Selecting the Right Method for Your Application

Your final decision should be guided by the most critical outcome for your project.

- If your primary focus is cost-effective coatings on simple, flat surfaces: Thermal or electron beam evaporation provides a direct and efficient solution.

- If your primary focus is high-density, durable films with strong adhesion: Magnetron sputtering is a robust and widely used industry standard.

- If your primary focus is coating complex 3D shapes with perfect uniformity: Chemical Vapor Deposition (CVD) is the superior choice for its conformal capabilities.

- If your primary focus is ultimate precision and pinhole-free films: Atomic Layer Deposition (ALD) provides unparalleled control, down to the single atomic layer.

By matching the inherent strengths of each method to your specific application, you can ensure a reproducible and high-yield manufacturing process.

Summary Table:

| Method | Type | Key Mechanism | Key Advantage | Ideal For |

|---|---|---|---|---|

| Evaporation | PVD | Heating source material to vaporize atoms | High speed, cost-effective for simple shapes | Simple, flat surfaces |

| Sputtering | PVD | Ejecting atoms from a target using plasma ions | Dense, adherent, high-quality films | Durable coatings requiring strong adhesion |

| CVD | Chemical | Chemical reaction of precursor gases on substrate | Excellent conformal coverage on complex shapes | Coating intricate 3D structures uniformly |

| ALD | CVD (Advanced) | Sequential, self-limiting surface reactions | Atomic-level control, pinhole-free films | Ultimate precision and uniformity |

Struggling to select the right vacuum deposition method for your project? The experts at KINTEK are here to help. We specialize in lab equipment and consumables for all your deposition needs, from sputtering targets to CVD precursors. Our team can guide you to the optimal solution for achieving the perfect film properties—whether you need high adhesion, conformal coverage, or atomic-level precision. Contact us today (#ContactForm) to discuss your specific application and let KINTEK enhance your laboratory's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition