The most critical precautions in sampling are to clearly define your target population, ensure your sample size is statistically adequate, use a randomization method to select participants, and actively work to minimize non-response bias. These steps are fundamental to ensuring the collected data is a true representation of the group you intend to study, making your findings valid and reliable.

The core purpose of taking precautions in sampling is to defend against bias. Every decision, from how you define your population to how you handle non-responses, is a deliberate step to ensure your sample is a miniature, accurate reflection of the whole, rather than a distorted snapshot.

The Foundation: Defining Your Scope

Before you collect a single piece of data, you must establish a clear and rigorous foundation. Errors made at this stage are almost impossible to correct later.

Clearly Define the Target Population

Your target population is the specific group you want to draw conclusions about. Vague definitions lead to invalid results.

Be precise about inclusion and exclusion criteria. Instead of "university students," specify "full-time undergraduate students aged 18-22 at University X during the 2023-2024 academic year."

Develop a Robust Sampling Frame

A sampling frame is the actual list of individuals from which the sample is drawn (e.g., a student registration list, a list of all company employees).

The ideal frame perfectly matches your target population. If it doesn't, you risk coverage error, where parts of the population are either left out or overrepresented.

The Mechanics of Sound Sampling

With a clear population and frame, the next set of precautions involves the technical execution of selecting your sample.

Select the Appropriate Sampling Method

The choice between probability and non-probability sampling is a critical decision.

Probability sampling (like simple random sampling) gives every individual an equal, non-zero chance of being selected. This is the gold standard for creating a representative sample.

Non-probability sampling (like convenience sampling) relies on the subjective judgment of the researcher. It is faster and cheaper but carries a high risk of bias and should not be used to make generalizations about a whole population.

Determine an Adequate Sample Size

A sample that is too small cannot produce reliable conclusions. The results will be heavily influenced by chance.

Use a sample size calculator or statistical formula to determine the minimum number needed based on your population size, desired margin of error, and confidence level. A larger sample generally reduces sampling error but also increases cost.

Ensure True Randomization

If you are using probability sampling, the selection process must be genuinely random.

Avoid "human" randomness, such as picking names that seem representative. Use a random number generator or a systematic selection method (e.g., selecting every 10th person from a list after a random start).

Common Pitfalls and Biases to Avoid

Vigilance against bias is the hallmark of a skilled researcher. These common errors can undermine the credibility of your entire study.

Guard Against Selection Bias

This occurs when your selection method systematically favors certain individuals or groups over others.

A classic example is using a telephone directory as a sampling frame, which excludes people with unlisted numbers or those who only use mobile phones. This systematically underrepresents certain demographics.

Minimize Non-Response Bias

This powerful bias occurs when the people who choose not to participate in your study are systematically different from those who do.

For example, if you survey employees about job satisfaction, those who are least satisfied may be the least likely to respond, skewing your results toward a falsely positive conclusion. Actively follow up with non-responders to mitigate this.

Recognize and Address Response Bias

This happens when participants provide inaccurate or untruthful answers.

This can be caused by poorly worded or leading questions, a desire to be socially acceptable, or a misunderstanding of the question. Pilot test your survey questions to ensure they are clear and neutral.

Making the Right Choice for Your Goal

The level of rigor you apply depends entirely on what you need to achieve with your data.

- If your primary focus is making statistically valid generalizations about a large population: You must use probability sampling, calculate an adequate sample size, and aggressively manage non-response bias.

- If your primary focus is exploring a new idea or a niche group: A non-probability method like purposive sampling may be appropriate, but you must acknowledge its severe limitations and not generalize the findings.

- If your primary focus is a quick pulse check with limited resources: A convenience sample is fast, but you must treat the results as anecdotal and directional at best, never as definitive proof.

Ultimately, rigorous and thoughtful sampling is the bedrock of credible data and trustworthy conclusions.

Summary Table:

| Precaution Category | Key Actions | Purpose |

|---|---|---|

| Foundation & Scope | Define target population; develop a robust sampling frame. | Establish clear boundaries to prevent coverage error. |

| Mechanics of Sampling | Choose probability/non-probability sampling; determine adequate sample size; ensure true randomization. | Create a representative and statistically sound sample. |

| Avoiding Bias | Guard against selection, non-response, and response bias. | Ensure data accurately reflects the entire population. |

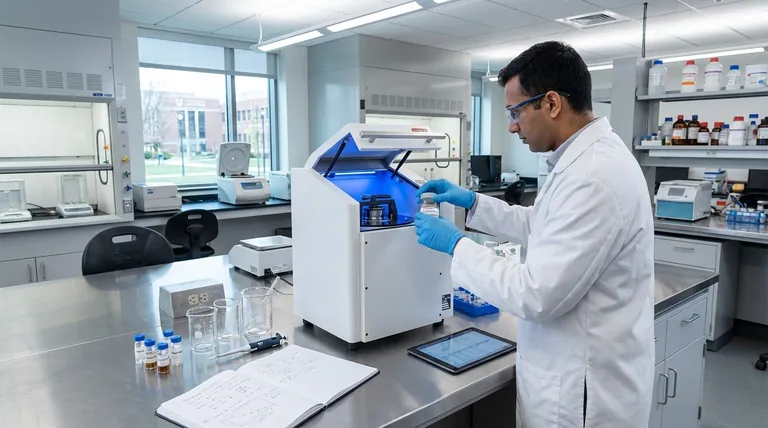

Need precise and reliable data for your research? KINTEK specializes in providing high-quality lab equipment and consumables that support rigorous sampling and data integrity. From sample preparation tools to analytical instruments, our solutions help you minimize errors and achieve trustworthy results. Contact our experts today to discuss how we can enhance your laboratory's sampling accuracy and efficiency.

Visual Guide

Related Products

- Lab Vibration Mill

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

People Also Ask

- Why is KBr and NaCl used in IR spectroscopy? Achieve Clear, Accurate Sample Analysis

- Can a reaction have multiple reaction types? Understand the Patterns and Processes

- How does a precision centrifuge contribute to electrochemical wastewater analysis? Ensure Data Integrity and Accuracy

- What are the steps of sample preparation? Master Milling, Pressing, and Sintering for Perfect Results

- What is the voltage of the e-beam evaporator? Understanding the 4-10 kV Range for Optimal Deposition

- What is a metal test called? A Guide to Heavy Metals Panels and Toxic Exposure Testing

- What is the sintering process? A Guide to Manufacturing with Powdered Materials

- What is the stress in sputtered thin films? Control Internal Forces for Reliable Film Performance