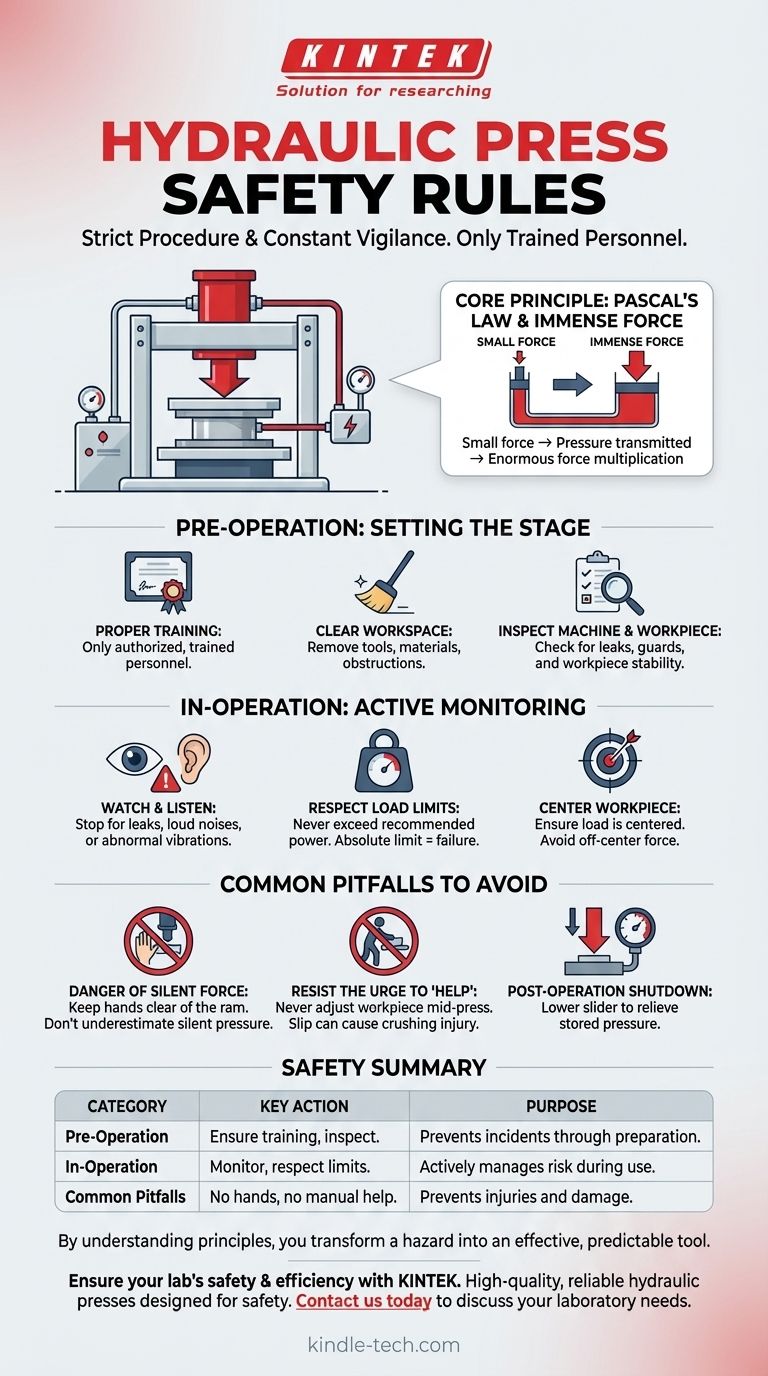

Operating a hydraulic press safely is a matter of strict procedure and constant vigilance. Fundamentally, only trained and authorized personnel should ever operate the machine. Before starting, the operator must ensure the workspace is clear, and during operation, they must stop immediately if any issues like oil leakage, excessive noise, or vibration occur, addressing the problem before resuming work.

A hydraulic press multiplies force silently and immensely based on Pascal's law. Safety is therefore not a one-time checklist, but a continuous process of preparation, active monitoring, and respecting the machine's known limits before you ever apply pressure.

The Core Principle: Understanding Immense Force

A hydraulic press may seem simple, but its power is deceptive. Understanding the source of this power is the first step toward respecting it.

How a Press Multiplies Force

A hydraulic press operates on Pascal's law, which states that pressure applied to a confined fluid is transmitted equally throughout that fluid.

By applying a small amount of force to a small piston, you generate pressure. This pressure is then transmitted through hydraulic fluid to a much larger piston, multiplying the initial force enormously. This is how a press can generate thousands of kilograms of force with minimal operator effort.

Pre-Operation Safety: Setting the Stage

The most critical safety steps happen before you ever turn the machine on. Thorough preparation prevents most common incidents.

Ensure Proper Training

No one should operate a hydraulic press without formal training. This training must cover not only the specific model's controls but also how to recognize the sounds and signs of normal versus abnormal operation.

Clear the Workspace

The area around the press must be completely clear of tools, materials, and obstructions. This provides a safe zone for the operator and prevents tripping hazards, ensuring you can move away quickly if an issue arises.

Inspect the Machine and Workpiece

Before every use, conduct a quick visual inspection. Look for any signs of hydraulic oil leaks on the machine or floor. Ensure all guards and safety features are in place and functioning. Confirm your workpiece is clean and properly sized for the press.

In-Operation Vigilance: Actively Managing the Load

Once the press is running, your full attention is required. You are not just an operator; you are actively monitoring a high-energy event.

Watch and Listen for Warning Signs

Stop the press immediately if you notice serious oil leakage, hear loud or unusual noises, or feel abnormal vibration. These are all indicators of a potential mechanical or hydraulic failure.

Respect the Load Limits

Every press has a maximum recommended load and an absolute maximum limit. You must never exceed the maximum recommended power. The absolute limit is a structural failure point, not an operational target. Pushing the machine beyond its recommended capacity risks catastrophic failure.

Center the Workpiece Correctly

Always place the workpiece in the center of the press bed. Applying force to an off-center load (exceeding the maximum limit of eccentricity) can damage the press ram, break the workpiece, or cause the workpiece to be ejected at high speed.

Common Pitfalls to Avoid

The greatest danger with a hydraulic press is complacency. Because the force is applied slowly and quietly, operators can underestimate the immense energy being stored and applied.

The Danger of Silent Force

Unlike a loud, fast-moving mechanical stamp, a hydraulic press does its work with quiet, relentless pressure. This silence can lull operators into a false sense of security. Never place your hands or any body part near the ram or workpiece during operation.

Resisting the Urge to "Help"

Never attempt to hold or adjust a workpiece with your hands once the ram has begun to move. The force is far too great to overcome, and any slip can result in a severe crushing injury. If an adjustment is needed, fully retract the ram, release the pressure, and reset the workpiece safely.

Post-Operation Shutdown

After your work is complete, lower the slider or ram to its lowest position. This relieves any stored pressure within the hydraulic system, leaving the machine in a safe and stable state for the next user.

Applying These Principles to Your Work

Your specific responsibilities dictate where your safety focus should lie.

- If your primary focus is operating the press: Your key responsibility is constant vigilance—monitoring the machine's sounds, checking for leaks, and stopping immediately if anything seems abnormal.

- If your primary focus is supervising a workspace: Your main goal is ensuring rigorous preparation—enforcing rules about training, pre-operation inspections, and maintaining a clear work area at all times.

- If your primary focus is designing a pressing process: Your crucial task is to respect the machine's stated limits—always design your procedure to stay well within the manufacturer's recommended load, not the absolute maximum.

By understanding the principles behind the rules, you transform a potentially hazardous machine into an effective and predictable tool.

Summary Table:

| Safety Rule Category | Key Action | Purpose |

|---|---|---|

| Pre-Operation | Ensure proper training and inspect the machine/workpiece. | Prevents incidents through preparation. |

| In-Operation | Monitor for leaks, noise, vibration; respect load limits. | Actively manages risk during use. |

| Common Pitfalls | Never place hands near the ram; avoid adjusting a workpiece mid-press. | Prevents crushing injuries and machine damage. |

Ensure your lab's safety and efficiency with the right equipment. KINTEK specializes in high-quality, reliable lab equipment and consumables, including hydraulic presses designed with safety in mind. Our experts can help you select the perfect press for your application and provide guidance on safe operation protocols. Contact us today to discuss your laboratory needs and discover how KINTEK can support your work with dependable solutions.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What role does a laboratory hydraulic press play in preparing solid model materials? Standardize for Precise Data.

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- Why is a laboratory hydraulic press utilized for electrolyte pelletizing? Unlock High Ionic Conductivity

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data