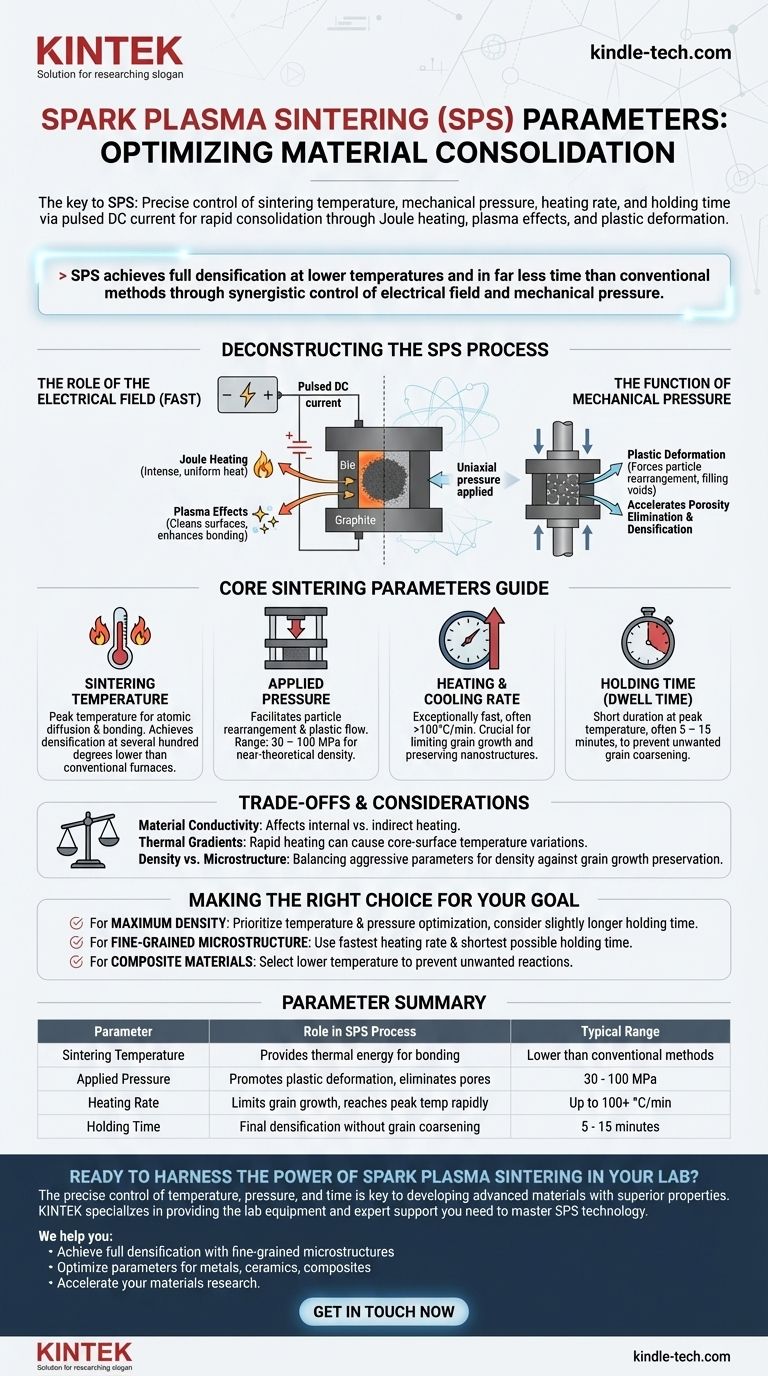

The key parameters for Spark Plasma Sintering (SPS) are the sintering temperature, applied mechanical pressure, heating rate, and holding time at the peak temperature. These variables are controlled through a pulsed Direct Current (DC) that passes through a conductive die and the material itself, enabling a unique combination of Joule heating, plasma effects, and plastic deformation to consolidate powders rapidly.

Spark Plasma Sintering is not simply a faster way to heat a material. Its power lies in the precise, synergistic control of an electrical field and mechanical pressure to achieve full densification at lower temperatures and in far less time than conventional methods.

Deconstructing the SPS Process

To effectively control the parameters, you must first understand the core mechanisms that set SPS apart from traditional sintering. The process relies on the simultaneous application of pressure and a high-amperage electrical current.

The Role of the Electrical Field

SPS, also known as a Field-Assisted Sintering Technique (FAST), uses a pulsed DC current. This current is the source of two primary heating phenomena.

First is Joule heating, where the electrical resistance of the graphite die and the powder compact generates intense, rapid, and uniform heat.

Second is the more debated "spark plasma" effect. The theory suggests that localized electrical discharges can occur in the gaps between powder particles, creating tiny pockets of plasma. This plasma cleans particle surfaces of oxides and contaminants, which dramatically enhances diffusion and bonding.

The Function of Mechanical Pressure

While the electrical field heats the material, a uniaxial pressure is constantly applied. This mechanical force serves a critical purpose: it promotes the plastic deformation of the heated, softened particles.

This pressure forces particles to rearrange, slide past one another, and deform to fill the voids between them, accelerating the elimination of porosity and driving the material toward full density.

A Guide to the Core Sintering Parameters

Mastering SPS involves balancing the following four parameters to suit your specific material and desired outcome.

Sintering Temperature

This is the peak temperature the material reaches during the cycle. It provides the thermal energy needed for atomic diffusion and particle bonding. A key advantage of SPS is its ability to achieve densification at temperatures several hundred degrees lower than conventional furnaces.

Applied Pressure

Typically ranging from 30 to 100 MPa, pressure is essential for facilitating powder rearrangement and plastic flow. Higher pressure can help close the final pores and achieve near-theoretical density, but excessive pressure can damage the tooling or the sample.

Heating and Cooling Rate

SPS allows for exceptionally fast heating rates, often exceeding 100°C per minute. This speed is crucial for limiting grain growth, which allows for the consolidation of nanostructured or fine-grained materials while preserving their unique microstructures.

Holding Time (Dwell Time)

This is the amount of time the sample is held at the peak sintering temperature. Due to the efficiency of the heating and pressure mechanisms, holding times in SPS are remarkably short, often just 5 to 15 minutes. This further prevents unwanted grain coarsening.

Understanding the Trade-offs and Considerations

While powerful, SPS is not a one-size-fits-all solution. Achieving optimal results requires an awareness of its underlying physics and potential limitations.

Material Conductivity is Key

The electrical conductivity of your powder compact has a significant impact. For conductive materials (like metals or MAX phases), the current passes through the sample itself, causing direct internal heating. For insulating materials (like many ceramics), the sample is heated indirectly by the surrounding hot graphite die.

Risk of Thermal Gradients

Although heating is rapid, temperature gradients can develop between the core and the surface of a large or low-conductivity sample. This can lead to variations in density and microstructure across the final part, requiring careful parameter tuning to mitigate.

Balancing Density and Microstructure

There is an inherent trade-off between achieving full density and preserving a fine-grained microstructure. Aggressive parameters—high temperature, high pressure, or long holding times—will produce a very dense part but may also cause undesirable grain growth. The goal is to find the processing window that achieves your required density while minimizing microstructural change.

Making the Right Choice for Your Goal

The ideal parameters are entirely dependent on your objective. Use the following guidelines as a starting point for process optimization.

- If your primary focus is achieving maximum density: Prioritize optimizing the temperature and applied pressure, potentially using a slightly longer holding time to ensure all porosity is eliminated.

- If your primary focus is preserving a fine-grained microstructure: Use the fastest possible heating rate and the shortest holding time that achieves your minimum acceptable density.

- If your primary focus is sintering a composite material: Carefully select a lower sintering temperature to prevent unwanted chemical reactions or diffusion between the different phases.

Mastering these parameters allows you to leverage the full potential of Spark Plasma Sintering to fabricate advanced materials that are simply not possible with conventional techniques.

Summary Table:

| Parameter | Role in SPS Process | Typical Range |

|---|---|---|

| Sintering Temperature | Provides thermal energy for atomic diffusion and bonding. | Often several hundred degrees lower than conventional methods. |

| Applied Pressure | Promotes particle rearrangement and plastic deformation to eliminate pores. | 30 - 100 MPa |

| Heating Rate | Limits grain growth by rapidly reaching the sintering temperature. | Up to 100+ °C/min |

| Holding Time | Allows for final densification at peak temperature without excessive grain coarsening. | 5 - 15 minutes |

Ready to harness the power of Spark Plasma Sintering in your lab?

The precise control of temperature, pressure, and time is key to developing advanced materials with superior properties. KINTEK specializes in providing the lab equipment and expert support you need to master SPS technology.

We help you:

- Achieve full densification while preserving fine-grained microstructures.

- Optimize sintering parameters for metals, ceramics, and composites.

- Accelerate your materials research with rapid and efficient consolidation.

Contact our experts today to discuss how our SPS solutions can advance your laboratory's capabilities.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is a SPS machine? A Guide to Rapid, High-Performance Material Fabrication

- Why is maintaining a high-vacuum environment necessary when using a vacuum hot pressing furnace? Expert Insights

- Why is a Vacuum Hot Pressing Furnace (VHP) preferred for aluminum matrix composites? Achieve Full Density & Bond Strength

- What is the necessity of pre-pressing composite powders? Enhance Stability in Vacuum Hot-Pressing Sintering

- What is the densification mechanism of hot isostatic pressing? Achieve Perfect Material Density

- What is hot isostatic pressing process? Enhance Material Performance with HIP Technology

- How does a vacuum hot press (VHP) contribute to the densification of Al-Cu-ZrC composite materials? Key VHP Benefits

- How does the hydraulic pressing device of a vacuum hot press furnace work? Maximize Metal Matrix Composite Density