Graphene synthesis is broadly divided into two fundamental strategies: "top-down" methods that break down graphite into single layers, and "bottom-up" methods that build graphene atom-by-atom. The most prominent techniques are mechanical exfoliation for research, liquid-phase exfoliation for bulk production, and Chemical Vapor Deposition (CVD) for high-quality electronics.

The central challenge in graphene production is a trade-off between quality, scale, and cost. While simple methods can produce small or lower-quality amounts of graphene, only complex, controlled processes like CVD can create the large, pristine sheets required for advanced applications.

The "Top-Down" Approach: Starting from Graphite

Top-down methods are conceptually simple, as they involve separating the atomic layers of graphite, a naturally abundant material. This approach is often used for creating graphene dispersions or for fundamental studies.

Mechanical Exfoliation

This is the original "Scotch tape" method, where adhesive tape is used to peel away layers from a piece of graphite until a single, monolayer sheet is isolated.

While it can produce pristine, defect-free graphene flakes with exceptional electrical quality, the process is manual, yields very small samples, and is not scalable for any industrial purpose. It remains a crucial technique for fundamental scientific research.

Liquid-Phase Exfoliation

This method uses high-energy processes like sonication to break apart graphite in a liquid solvent. The liquid stabilizes the separated graphene flakes, preventing them from restacking.

Liquid-phase exfoliation is suitable for mass production of graphene inks and composites. However, the resulting material typically consists of smaller flakes with more defects, leading to lower electrical quality compared to other methods.

The "Bottom-Up" Approach: Building from Atoms

Bottom-up synthesis involves constructing graphene from carbon-containing precursor molecules on a substrate. This approach offers precise control over the final material's quality and dimensions.

Chemical Vapor Deposition (CVD)

CVD is widely regarded as the most promising method for producing large-area, high-quality graphene suitable for electronics. The process involves flowing a carbon-containing gas, such as methane (CH4), over a hot metal foil substrate, typically copper (Cu).

At high temperatures, the gas decomposes, and carbon atoms arrange themselves into the honeycomb lattice of graphene on the metal surface. The continuous graphene sheet is then carefully transferred to a target substrate (like silicon) for use in devices.

Optimizing CVD for Peak Performance

The quality of CVD graphene depends heavily on synthesis parameters like temperature, gas flow rates, and the nature of the substrate.

Researchers optimize growth by studying how graphene "islands" nucleate and merge on the substrate. By controlling these factors, it is possible to minimize defects and grow large, single-crystalline domains, which are essential for high-performance electronics.

Sublimation of Silicon Carbide (SiC)

Another high-temperature bottom-up method involves heating a silicon carbide wafer to extreme temperatures (over 1100°C) in a vacuum. The silicon atoms sublimate (turn into a gas) from the surface, leaving behind carbon atoms that rearrange into graphene layers.

This method produces high-quality graphene directly on a semiconducting wafer, eliminating the need for a transfer step. However, the extremely high cost and inflexibility of SiC substrates limit its widespread use.

Understanding the Trade-offs

No single synthesis method is universally superior; each comes with distinct advantages and disadvantages that make it suitable for different applications.

Quality vs. Simplicity

Mechanical exfoliation produces the highest-quality graphene but is fundamentally unscalable. Top-down methods like liquid exfoliation are simpler and cheaper for bulk production but sacrifice the pristine crystalline structure and electrical performance.

Scalability vs. Control

CVD is the champion of scalability for high-performance applications. It allows for the production of meter-scale graphene sheets with good uniformity, a feat impossible with exfoliation methods. This control, however, comes at the cost of process complexity and equipment expense.

The Critical Transfer Step

A significant challenge unique to CVD on metal foils is the necessity of transferring the fragile, one-atom-thick film to a functional substrate. This transfer process can introduce defects, wrinkles, and contamination, potentially compromising the graphene's inherent properties.

Selecting the Right Synthesis Method

The ideal method is dictated entirely by your application's end goal and its tolerance for cost, scale, and material quality.

- If your primary focus is fundamental research: Mechanical exfoliation provides the highest-quality, pristine flakes for lab-scale experiments.

- If your primary focus is large-area electronics: Chemical Vapor Deposition (CVD) is the most viable path for producing uniform, high-quality graphene sheets.

- If your primary focus is bulk composites or conductive inks: Liquid-phase exfoliation offers a scalable, cost-effective solution where peak electrical performance is not the primary requirement.

Understanding this landscape empowers you to choose the synthesis route that directly aligns with your technical and commercial objectives.

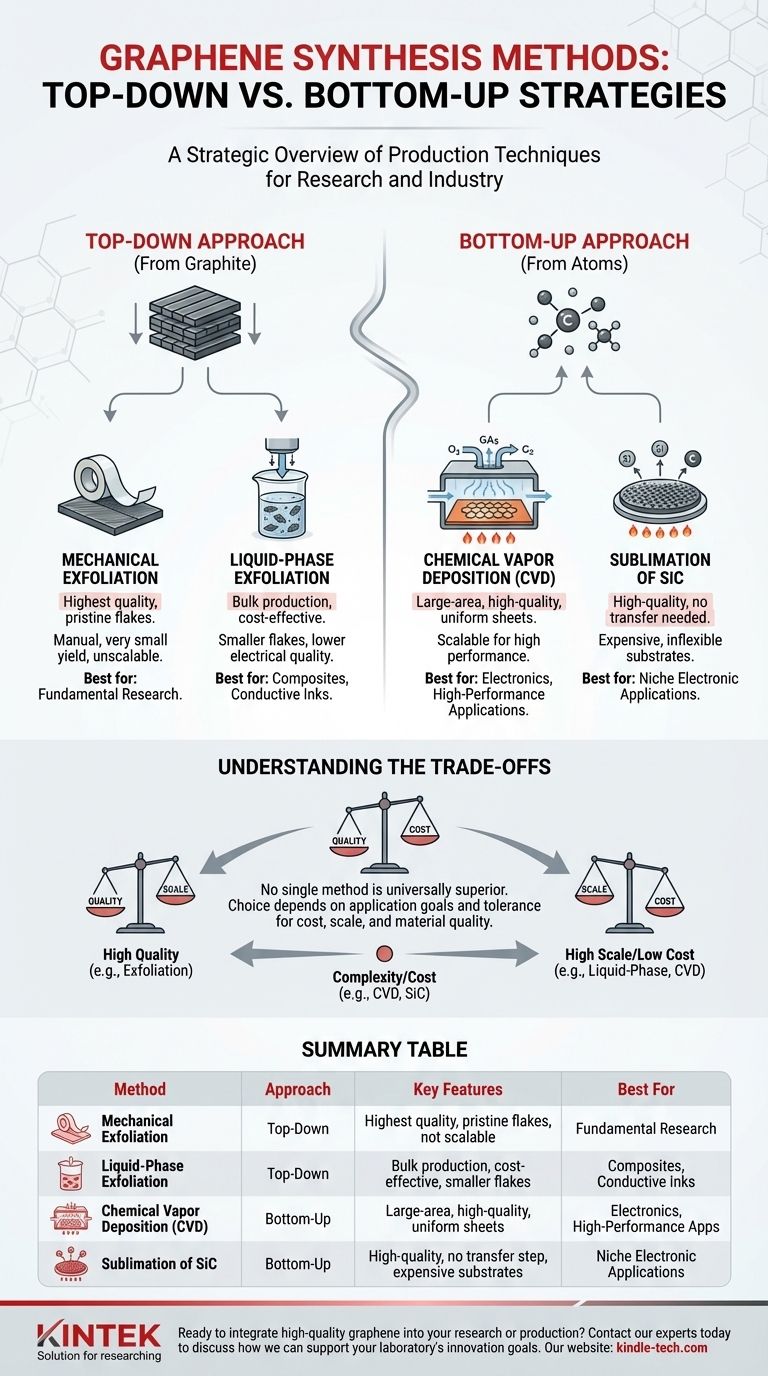

Summary Table:

| Method | Approach | Key Features | Best For |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Highest quality, pristine flakes, not scalable | Fundamental Research |

| Liquid-Phase Exfoliation | Top-Down | Bulk production, cost-effective, smaller flakes | Composites, Conductive Inks |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Large-area, high-quality, uniform sheets | Electronics, High-Performance Applications |

| Sublimation of SiC | Bottom-Up | High-quality, no transfer step, expensive substrates | Niche Electronic Applications |

Ready to integrate high-quality graphene into your research or production? The right synthesis method is critical to your success. KINTEK specializes in providing the advanced lab equipment, including CVD systems, and expert consultation needed to produce graphene for your specific application—whether for cutting-edge electronics, composites, or fundamental research. Contact our experts today to discuss how we can support your laboratory's innovation goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods