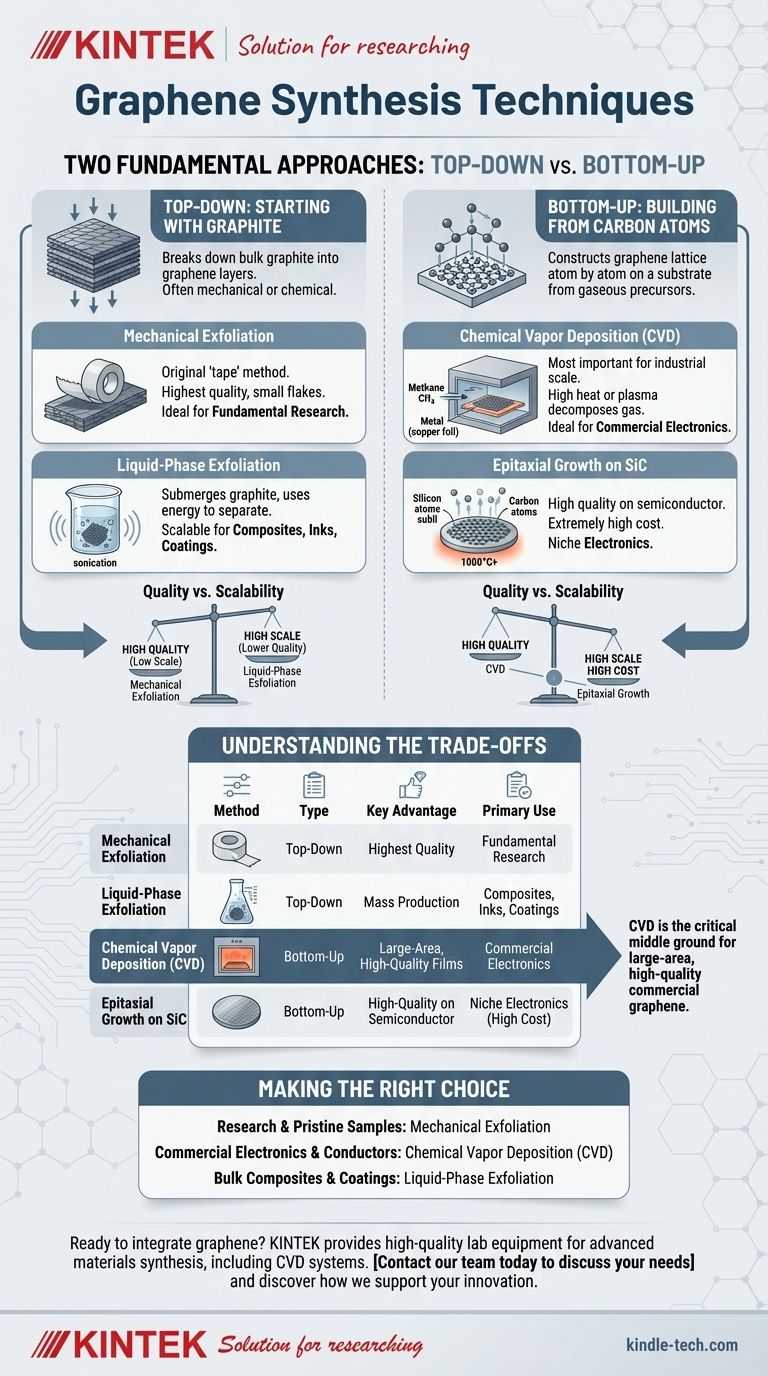

To synthesize graphene, materials scientists use two primary approaches: "top-down" methods that break down graphite, and "bottom-up" methods that build graphene from individual carbon atoms. While several techniques exist within these categories, Chemical Vapor Deposition (CVD) has become the most important and widely used method for creating the large-area, high-quality graphene needed for commercial applications.

The core challenge in graphene synthesis is a trade-off between quality and scale. Top-down methods like exfoliation are effective for bulk production or lab research, but for creating pristine, single-layer sheets suitable for advanced electronics, bottom-up techniques like CVD are the undisputed standard.

The Two Fundamental Approaches to Graphene Synthesis

Understanding the landscape of graphene production begins with the two opposing philosophies for its creation. Each approach is suited for different end goals.

Top-Down: Starting with Graphite

The top-down strategy involves starting with bulk graphite—essentially a stack of countless graphene layers—and separating those layers.

These methods are often mechanically or chemically intensive, designed to overcome the strong forces holding the graphene sheets together.

Bottom-Up: Building from Carbon Atoms

The bottom-up strategy involves constructing the graphene lattice atom by atom on a substrate.

This is a synthesis process where gaseous carbon-containing molecules are broken down, allowing the carbon atoms to arrange themselves into the characteristic hexagonal honeycomb structure.

A Closer Look at Key Synthesis Techniques

While many variations exist, a few key techniques define the field, each with distinct advantages and disadvantages.

Mechanical Exfoliation (Top-Down)

This is the original technique used to discover graphene, often famously associated with using adhesive tape to peel layers from graphite.

It produces extremely high-quality, pristine graphene flakes. However, the process yields very small samples and is not scalable, limiting its use almost exclusively to fundamental research and lab studies.

Liquid-Phase Exfoliation (Top-Down)

This technique involves submerging graphite in a liquid and using energy, such as sonication, to break it apart into graphene sheets.

It is a method well-suited for mass production of graphene flakes, which can then be used in composites, inks, and coatings. The trade-off is that the resulting material has lower electrical quality compared to other methods.

Chemical Vapor Deposition (CVD) (Bottom-Up)

CVD is the most promising and popular technique for industrial-scale graphene synthesis. The process involves heating a metal substrate, typically a copper foil, in a vacuum and introducing a hydrocarbon gas like methane.

At high temperatures, the gas decomposes, and carbon atoms deposit onto the metal surface, forming a continuous, single-layer sheet of high-quality graphene over a large area. This makes it ideal for electronics and other advanced applications.

There are two main types of CVD: Thermal CVD, which relies on high heat, and Plasma-enhanced CVD, which uses plasma to enable the reaction at lower temperatures.

Epitaxial Growth on Silicon Carbide (Bottom-Up)

This method involves heating a silicon carbide (SiC) wafer to very high temperatures (over 1000°C), causing the silicon atoms to sublimate, or turn into a gas.

The remaining carbon atoms on the surface rearrange themselves into graphene layers. While this produces high-quality graphene directly on a semiconducting substrate, the extremely high cost of SiC wafers makes it a niche and expensive technique.

Understanding the Trade-offs

Choosing a synthesis method is not about finding the "best" one, but the one best suited for a specific application. The decision almost always hinges on the balance between quality, scale, and cost.

Quality vs. Scalability

Mechanical exfoliation produces the highest-quality graphene but is completely unscalable. Conversely, liquid-phase exfoliation is highly scalable for bulk production but yields material with more defects and lower electrical performance.

CVD represents the critical middle ground, offering a path to producing large-area, high-quality graphene films that are suitable for demanding commercial use.

The Role of the Substrate

Bottom-up methods like CVD are dependent on a substrate (like copper) to grow the graphene. This film must then be transferred to a target substrate (like silicon) for use in electronics, a process which can introduce defects.

Methods like SiC sublimation avoid this transfer step, but at a significantly higher initial material cost.

Cost and Complexity

Cost is a major driver. CVD has emerged as a leader because its precursors (like methane gas) are relatively inexpensive and the process has matured significantly.

Specialized techniques like the "vapor-trapping method" can produce larger single-crystal graphene grains but add complexity to the standard CVD process.

Making the Right Choice for Your Application

Your final goal dictates the appropriate synthesis method.

- If your primary focus is fundamental research on pristine samples: Mechanical exfoliation remains the gold standard for creating the highest-quality flakes for laboratory analysis.

- If your primary focus is commercial electronics or transparent conductors: Chemical Vapor Deposition (CVD) is the established industry method for producing large, uniform, high-quality graphene films.

- If your primary focus is creating bulk composites, inks, or coatings: Liquid-phase exfoliation offers the most viable path to mass production where ultimate electronic quality is not the primary concern.

Ultimately, selecting the correct synthesis technique is the most critical first step in harnessing the potential of graphene for any application.

Summary Table:

| Method | Type | Key Advantage | Primary Use |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Highest Quality | Fundamental Research |

| Liquid-Phase Exfoliation | Top-Down | Mass Production | Composites, Inks, Coatings |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Large-Area, High-Quality Films | Commercial Electronics |

| Epitaxial Growth on SiC | Bottom-Up | High-Quality on Semiconductor | Niche Electronics (High Cost) |

Ready to integrate graphene into your research or production? The right synthesis technique is critical for success. KINTEK specializes in providing the high-quality lab equipment and consumables needed for advanced materials synthesis, including CVD systems. Our experts can help you select the perfect tools for your graphene application. Contact our team today to discuss your specific needs and discover how we can support your innovation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Wire Drawing Die Blanks for Precision Applications

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing