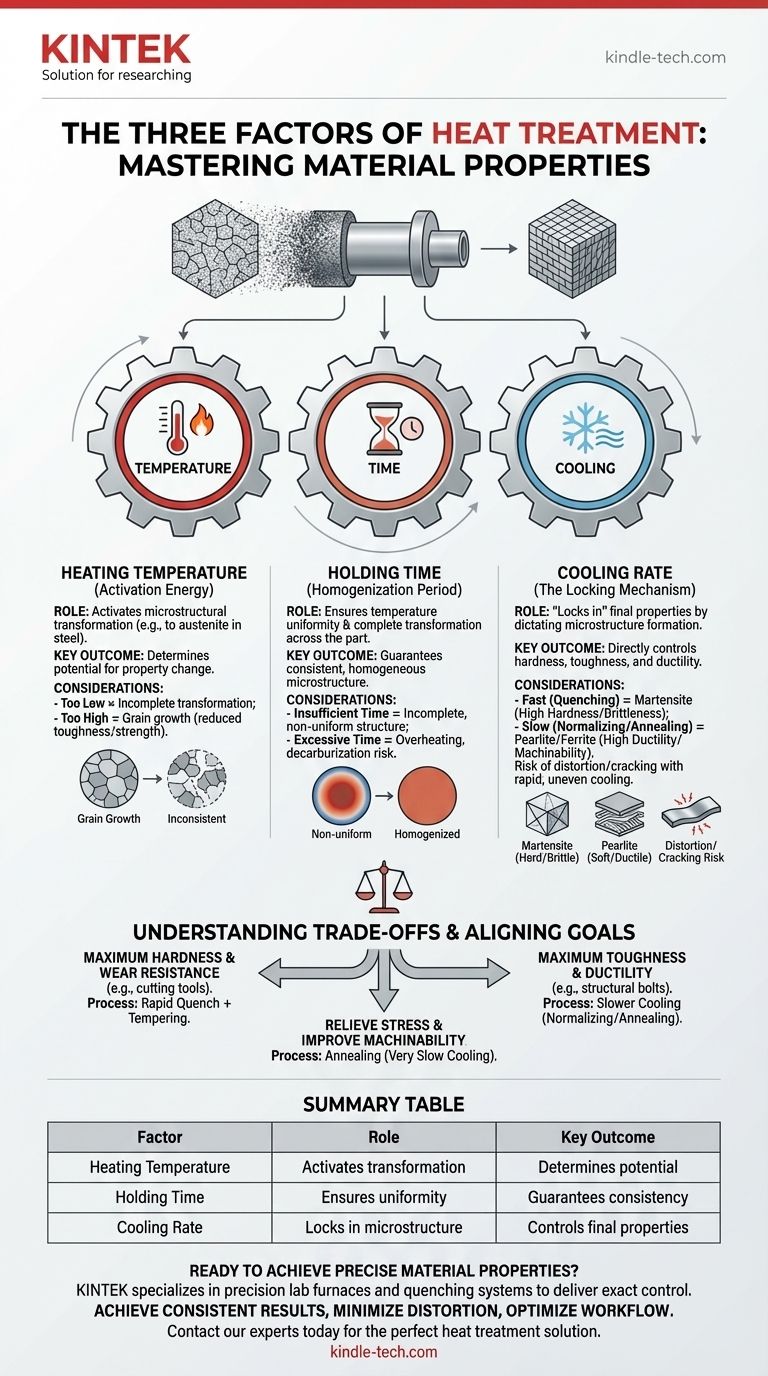

In short, the three fundamental factors that govern any heat treatment process are the heating temperature, the holding time at that temperature, and the cooling rate. These three variables are the levers you pull to intentionally change a material's internal structure and, consequently, its mechanical properties like hardness, toughness, and ductility.

The core principle of heat treatment is not just about heating and cooling metal. It's about using temperature, time, and cooling speed as precise tools to control the material's microscopic crystal structure, which directly dictates its final real-world performance.

The Role of Each Factor in Transforming Metal

Understanding heat treatment requires seeing these three factors as an interconnected system. Changing one variable directly impacts the role and effect of the others.

Factor 1: Heating Temperature (The Activation Energy)

The temperature to which a material is heated is arguably the most critical factor. It provides the thermal energy necessary for transformative changes to occur in the material's crystal structure (its microstructure).

For steels, this typically means heating above a critical transformation point to form a structure called austenite. If the temperature is too low, this essential transformation will not fully complete, and the final properties will be inconsistent.

Conversely, heating to an excessively high temperature can cause a permanent, undesirable condition called grain growth. This leads to larger internal crystals, which can reduce the material's toughness and strength after cooling.

Factor 2: Holding Time (The Homogenization Period)

Once the material reaches the target temperature, it must be held there for a specific period. This is often called soaking time.

The primary purpose of holding is to ensure two things: temperature uniformity and complete transformation. The entire volume of the part, from the surface to the core, must reach the target temperature. Thicker sections naturally require longer holding times.

This period also gives the internal structure enough time to fully transform. For example, in steel, it allows carbon atoms to dissolve evenly into the austenite structure, much like allowing sugar to fully dissolve in water before cooling it. Insufficient holding time results in an incomplete and non-uniform microstructure.

Factor 3: Cooling Rate (The Locking Mechanism)

The rate at which the material is cooled from the holding temperature is what "locks in" the desired final properties. The speed of cooling dictates which new crystal structures can form as the material's atoms rearrange.

A very fast cooling rate, known as quenching (e.g., in water or oil), is a violent process. It traps the atoms in a highly stressed, hard, and brittle structure called martensite. This is how you achieve maximum hardness.

A slow cooling rate, such as letting the part cool in still air (normalizing) or inside the furnace (annealing), gives the atoms ample time to rearrange into soft, ductile structures like pearlite and ferrite. This process relieves internal stress and maximizes machinability.

Understanding the Trade-offs

Heat treatment is a balancing act. Optimizing for one property often comes at the expense of another. Understanding these compromises is essential for achieving a successful outcome.

Hardness vs. Brittleness

The most fundamental trade-off is between hardness and brittleness. A steel part quenched to its maximum hardness is also extremely brittle and may shatter under impact. This is why a secondary heat treatment process called tempering is almost always performed after quenching to restore some toughness, albeit at a slight cost to hardness.

The Risk of Distortion and Cracking

Rapid cooling is not uniform. The surface of a part cools and contracts faster than its core, creating immense internal stresses. In parts with complex shapes, sharp corners, or varying thicknesses, this stress can cause the part to warp, distort, or even crack. This risk dictates the choice of quenching medium (water is more severe than oil, which is more severe than air).

Overheating and Decarburization

Exceeding the correct heating temperature or holding the part for too long can be just as detrimental as improper cooling. Overheating causes irreversible grain growth, weakening the material. Furthermore, holding at high temperatures in an oxygen-rich atmosphere can cause decarburization, where carbon atoms diffuse out of the surface, leaving a soft outer "skin" on the hardened part.

Aligning Heat Treatment with Your Goal

Your choice of temperature, time, and cooling rate must be driven by the intended application of the component.

- If your primary focus is maximum hardness and wear resistance (e.g., cutting tools, bearings): You will use a process involving a rapid quench from the austenitizing temperature, followed by tempering to reduce brittleness.

- If your primary focus is maximum toughness and ductility (e.g., structural bolts, chassis components): You will use a process with a slower cooling rate, like normalizing or annealing, to produce a more refined and less stressed microstructure.

- If your primary focus is relieving internal stress and improving machinability (e.g., preparing a raw forging for machining): You will use an annealing process, which involves very slow furnace cooling to produce the softest, most stable material condition possible.

Ultimately, mastering heat treatment is about deliberately manipulating these three factors to engineer the exact material properties your application demands.

Summary Table:

| Factor | Role in Heat Treatment | Key Outcome |

|---|---|---|

| Heating Temperature | Activates microstructural transformation (e.g., to austenite). | Determines the potential for property change. |

| Holding Time | Ensures temperature uniformity and complete transformation. | Guarantees a consistent and homogeneous microstructure. |

| Cooling Rate | Locks in the final microstructure (e.g., martensite or pearlite). | Directly controls the final hardness, toughness, and ductility. |

Ready to Achieve Precise Material Properties in Your Lab?

Mastering the interplay of temperature, time, and cooling is essential for successful heat treatment. Whether you need to harden a tool, toughen a component, or relieve stress, having the right equipment is critical.

KINTEK specializes in precision lab furnaces and quenching systems that deliver the exact control your processes demand. Our solutions help you:

- Achieve consistent results with precise temperature uniformity and programmable cooling rates.

- Minimize distortion and cracking with controlled thermal cycles.

- Optimize your workflow with reliable equipment built for laboratory needs.

Let's discuss your specific application. Contact our experts today to find the perfect heat treatment solution for your laboratory.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does tempering reduce hardness? Achieve the Perfect Balance of Toughness and Durability

- Do you need to heat the clean crucible before using it? Prevent Thermal Shock and Ensure Process Accuracy

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What is the effect of calcination? Unlock Material Transformation for Industrial Processes

- What is the construction of a muffle furnace? A Deep Dive into Its Core Systems