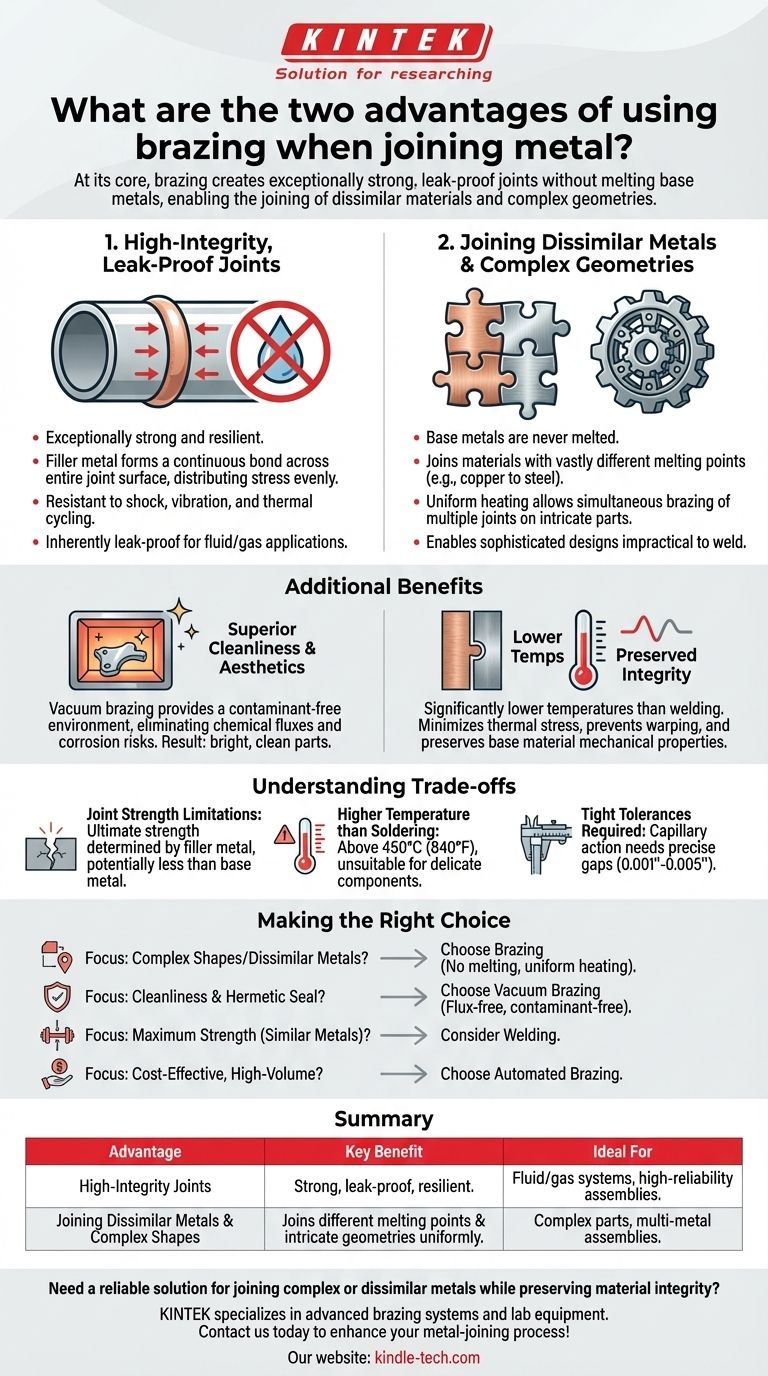

At its core, brazing offers two primary advantages over other metal-joining methods: it creates exceptionally strong, leak-proof joints without melting the base metals, and it allows for the joining of dissimilar materials or highly complex geometries that would be impossible to weld. This unique combination preserves the integrity of the parent materials while enabling sophisticated designs.

While often compared to welding, the true value of brazing lies in its finesse. It is an ideal solution for creating high-integrity, clean, and dimensionally stable assemblies, particularly when working with delicate components, dissimilar metals, or complex part configurations.

The Core Benefits of Brazing

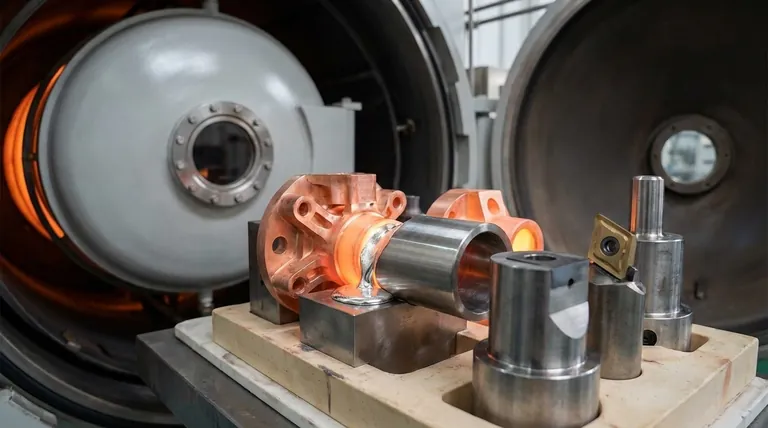

Brazing works by heating two or more close-fitting parts and introducing a filler metal that melts at a lower temperature than the base materials. This filler is drawn into the gap between the parts by capillary action, creating a permanent metallurgical bond upon cooling.

Creating High-Integrity Joints

A properly executed brazed joint is incredibly strong and resilient. The filler metal forms a bond with both base materials across the entire surface area of the joint, distributing stress evenly.

This results in assemblies that are highly resistant to shock, vibration, and thermal cycling. Because the bond is continuous and complete, brazed joints are also inherently leak-proof, making the process ideal for fluid and gas applications.

Joining Dissimilar Metals and Complex Geometries

This is a major advantage over welding. Since the base metals are never melted, you can easily join materials with vastly different melting points, such as copper to steel or tungsten carbide to steel.

Furthermore, because the entire assembly is often heated uniformly in a furnace, multiple joints on a complex part can be brazed simultaneously. This allows for the creation of intricate assemblies that would be difficult or impractical to produce with a localized heat source like a welding torch.

Achieving Superior Cleanliness and Aesthetics

Processes like vacuum brazing provide a contaminant-free environment that eliminates the need for chemical fluxes, which can cause corrosion if not meticulously cleaned post-process.

The result is a bright, clean part straight from the furnace with no flux residue or significant oxidation. This is critical for high-value industries like aerospace, medical, and semiconductor manufacturing, where joint purity is paramount.

Preserving Base Metal Integrity

Welding involves melting the base metals, creating a "heat-affected zone" that can alter the material's properties, introduce residual stresses, and cause distortion.

Brazing uses significantly lower temperatures and more uniform heating. This gentle process minimizes thermal stress, prevents warping, and preserves the mechanical and metallurgical properties of the parent materials, which is crucial for precision components.

Understanding the Trade-offs

No process is perfect. To choose brazing effectively, you must understand its limitations compared to other joining methods.

Joint Strength Limitations

While very strong, a brazed joint's ultimate strength is determined by the filler metal, which is typically not as strong as the base metals. For applications requiring the absolute maximum tensile strength between two similar materials, a full-penetration weld may be superior.

Higher Temperature than Soldering

Brazing occurs at temperatures above 450°C (840°F), while soldering occurs below this threshold. This higher heat input makes brazing unsuitable for joining components that are extremely sensitive to heat, such as delicate electronics.

Requirement for Tight Tolerances

Capillary action, the fundamental principle of brazing, only works if the gap between the parts is very small and consistent—typically between 0.001" and 0.005". This demands more precise machining and fixturing than many welding or mechanical fastening processes.

Initial Equipment Cost

While automated brazing can be highly cost-effective for high-volume production, the initial capital investment can be substantial. A vacuum brazing furnace, for example, is a significant expenditure compared to a standard welding setup.

Making the Right Choice for Your Application

Selecting the correct joining process requires aligning the method's strengths with your primary goal.

- If your primary focus is joining complex shapes or dissimilar metals: Brazing is the superior choice, as it avoids melting the base materials and allows for uniform heating.

- If your primary focus is a clean, flux-free, and hermetically sealed joint: Vacuum brazing is the industry standard, especially for medical, aerospace, or high-vacuum applications.

- If your primary focus is maximum joint strength on similar metals: A properly designed weld may provide higher ultimate strength, assuming the component geometry is simple enough.

- If your primary focus is cost-effective, high-volume production: Automated brazing can offer significant time and labor savings by combining joining and heat-treating steps in a single cycle.

Ultimately, brazing empowers engineers to solve complex joining challenges where material integrity, precision, and cleanliness are non-negotiable.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High-Integrity Joints | Strong, leak-proof, and resilient to stress, shock, and vibration. | Fluid/gas systems, high-reliability assemblies. |

| Joining Dissimilar Metals & Complex Shapes | Joins materials with different melting points and intricate geometries uniformly. | Complex parts, assemblies of different metals (e.g., copper to steel). |

Need a reliable solution for joining complex or dissimilar metals while preserving material integrity?

KINTEK specializes in advanced brazing systems and lab equipment, offering the precision and cleanliness required for aerospace, medical, and semiconductor applications. Let our experts help you achieve superior, leak-proof joints with our state-of-the-art vacuum brazing furnaces and consumables.

Contact us today to discuss how we can enhance your metal-joining process!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining