The two most common types of joints used in brazing are the lap joint and the butt joint. These two designs form the foundation for nearly all brazing applications, with the choice between them dictated by the final part's strength requirements and dimensional constraints. The lap joint involves overlapping the two base metals, while the butt joint joins them edge-to-edge.

The decision between a lap and butt joint is a fundamental engineering trade-off. You must choose between the superior strength of a lap joint and the dimensional precision and flush finish of a butt joint.

The Lap Joint: The Foundation of Strength

The lap joint is the preferred design for most brazing applications precisely because it provides the opportunity to create a joint that is stronger than the base metals themselves. Its strength is derived from the large, shared surface area between the two overlapping components.

The Principle of Overlap

In a lap joint, the filler metal creates a bond across the entire faying (mating) surface area. This distributes the load over a much larger area compared to the cross-section of the individual parts, significantly increasing the joint's load-bearing capacity.

Designing for Optimal Strength

A widely accepted rule of thumb is to design the overlap to be at least three times the thickness of the thinnest base metal member. Following this rule typically ensures that if the part fails under stress, the base metal will fail before the brazed joint does.

Common Applications

You will find lap joints used in nearly every industry where strength and reliability are critical. This includes hydraulic and pneumatic tube fittings, attaching flanges to pipes, and joining electrical contacts where both mechanical strength and conductivity are essential.

The Butt Joint: Simplicity and Precision

A butt joint joins two pieces of metal in the same plane, connecting them end to end. While simple to prepare, it presents a significant limitation in terms of ultimate strength.

The Edge-to-Edge Design

The primary advantage of the butt joint is that it creates a smooth, flush surface with minimal change to the assembly's overall dimensions. This makes it ideal for applications where a clean appearance or tight dimensional tolerances are required.

The Inherent Strength Limitation

The strength of a butt joint is limited to the cross-sectional area of the thinnest part being joined. Because this bonding area is small, the joint will almost always be the weakest point in the assembly, unlike a properly designed lap joint.

When to Use a Butt Joint

Butt joints are best suited for applications where stress is not the primary concern. Common examples include joining the ends of a band saw blade or in certain decorative metalwork where a seamless appearance is more important than mechanical strength.

Understanding the Trade-offs

Choosing the right joint is not just about picking a design, but understanding the critical factors that govern the success of the braze itself.

Strength vs. Appearance

This is the central trade-off. The lap joint is strong but adds to the material thickness at the joint. The butt joint is dimensionally clean but mechanically weak. For a compromise, a scarf joint (a butt joint cut at an angle) can be used to increase surface area and strength while being less bulky than a true lap joint.

The Critical Role of Joint Clearance

For both joint types, the gap between the two base metals is the single most important factor for success. The ideal clearance allows the molten filler metal to be drawn fully into the joint by capillary action.

- Too tight: The filler metal cannot flow in, resulting in voids and a weak bond.

- Too loose: Capillary action is lost, and the joint's strength becomes dependent on the weaker filler metal alone.

Making the Right Choice for Your Goal

Your application's specific requirements will determine the correct joint design.

- If your primary focus is maximum strength and durability: Design a lap joint with an overlap of at least three times the thickness of the thinnest component.

- If your primary focus is a flush finish and maintaining original dimensions: Use a butt joint, but accept that it will be the weakest point in the assembly.

- If you need a compromise between strength and a clean profile: Consider a scarf joint to increase the bonding area without the full bulk of a lap joint.

Ultimately, understanding the principles of joint design is the true foundation of a successful and reliable brazed assembly.

Summary Table:

| Joint Type | Key Characteristic | Primary Advantage | Ideal Application |

|---|---|---|---|

| Lap Joint | Overlapping materials | Superior strength | Hydraulic fittings, structural components |

| Butt Joint | Edge-to-edge connection | Flush finish, dimensional precision | Decorative work, band saw blades |

Need help selecting the right joint design or brazing equipment for your laboratory application? KINTEK specializes in providing high-quality lab equipment and consumables for precise thermal processes like brazing. Our experts can help you choose the right tools and materials to ensure strong, reliable joints. Contact our team today to discuss your specific needs and enhance your lab's capabilities!

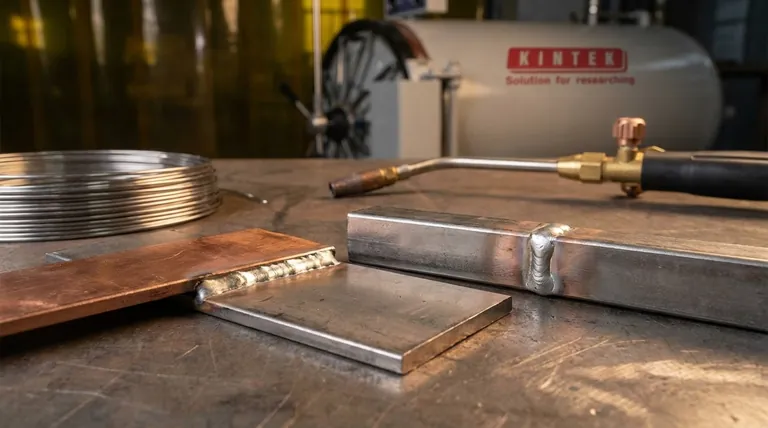

Visual Guide

Related Products

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

People Also Ask

- Which autoclave is used in microbiology lab? Gravity Displacement vs. Pre-Vacuum Explained

- What is the size of the autoclave? Choose the Right Capacity for Your Lab

- Is autoclave an instrument or equipment? A Clear Guide to Classification

- What is the use of autoclave in microbiology? Ensuring Sterile Conditions for Reliable Results

- Where should an autoclave be located in a lab? Balance Safety and Efficiency for Optimal Workflow