At its core, Chemical Vapor Deposition (CVD) is not a single technology but a family of processes. The primary types are distinguished by their operating pressure, temperature control, and the type of energy used to initiate the chemical reaction. Key variants include Atmospheric Pressure CVD (APCVD), Low-Pressure CVD (LPCVD), Plasma-Enhanced CVD (PECVD), and methods using lasers or light for energy.

The crucial insight is that different CVD methods exist to overcome specific limitations. The choice between them is a deliberate engineering trade-off, balancing the need for lower temperatures, higher purity, or better uniformity against process complexity and cost.

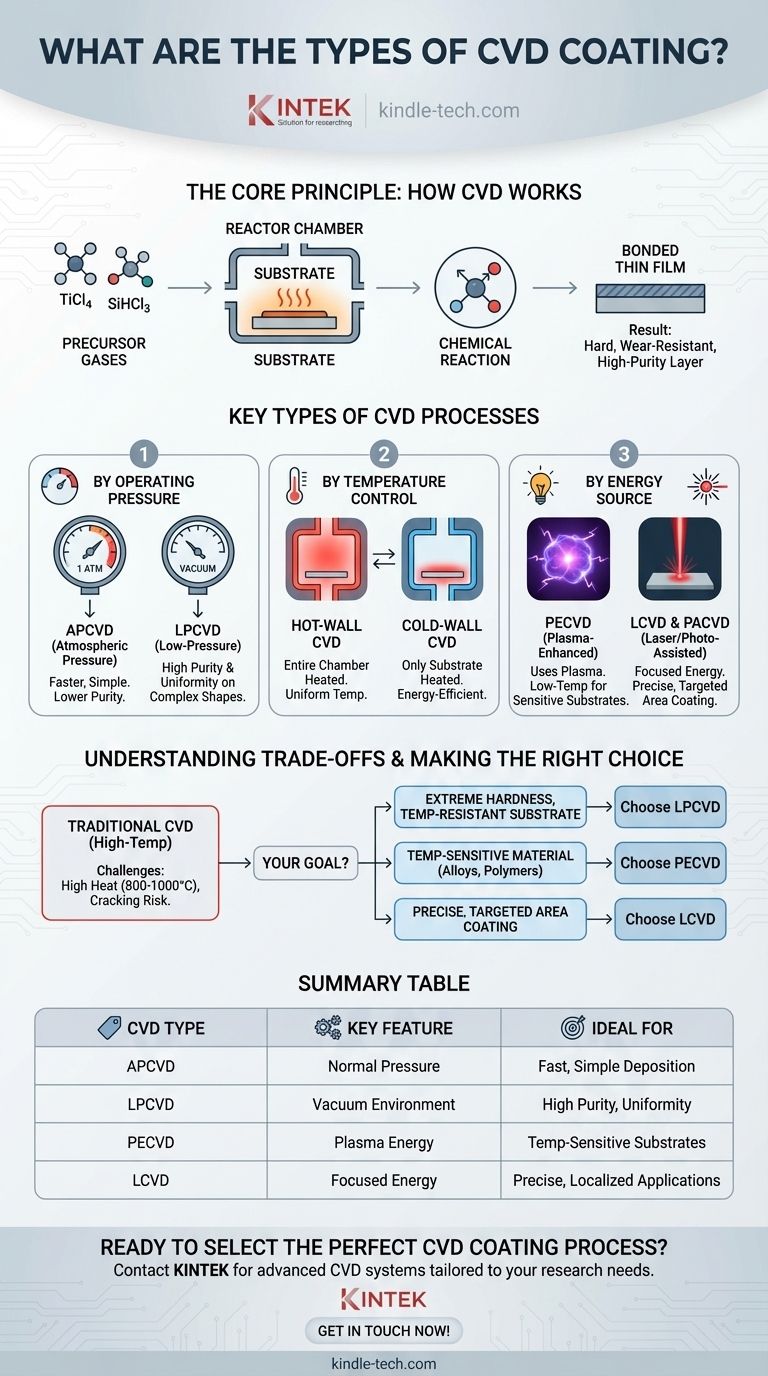

The Core Principle: How CVD Works

Before categorizing the types, it's essential to understand the fundamental process they all share. CVD is a method for applying a thin, durable film onto a surface through a controlled chemical reaction.

The Role of Precursors

The process begins with one or more volatile precursor gases, which contain the atoms of the desired coating material. For example, titanium tetrachloride (TiCl4) is a common precursor for titanium-based coatings, while trichlorosilane (SiHCl3) is used for silicon deposition.

The Chemical Reaction

These precursor gases are introduced into a reactor chamber containing the object to be coated, known as the substrate. The substrate is heated, and this thermal energy causes the precursor gases to react or decompose on its surface, depositing a solid thin film.

The Result: A Bonded Thin Film

The resulting coating—such as Titanium Nitride (TiN) or silicon—is not merely sitting on the surface; it is chemically bonded to the substrate. This creates an extremely hard, wear-resistant, and high-purity layer.

The Key Types of CVD Processes

The variations in the CVD process are designed to optimize the coating for different substrates and performance requirements. They are typically classified by the conditions inside the reactor.

Classification by Operating Pressure

The pressure inside the reactor dramatically affects the quality and uniformity of the coating.

- Atmospheric Pressure CVD (APCVD): This process operates at normal atmospheric pressure. It is simpler and faster but can sometimes result in lower film purity and uniformity compared to other methods.

- Low-Pressure CVD (LPCVD): By operating under a vacuum, LPCVD reduces unwanted gas-phase reactions. This allows for excellent coating uniformity and the ability to coat complex shapes evenly.

Classification by Reactor Temperature Control

How heat is applied to the substrate and the chamber is another critical distinction.

- Hot-Wall CVD: In this configuration, the entire reactor chamber is heated. This provides excellent temperature uniformity across the substrate but can lead to wasteful deposition on the chamber walls.

- Cold-Wall CVD: Here, only the substrate itself is heated, while the chamber walls remain cool. This method is more energy-efficient and minimizes unwanted coating on the reactor components.

Classification by Energy Source

To accommodate heat-sensitive materials, some CVD processes use alternative energy sources instead of relying solely on high temperatures.

- Plasma-Enhanced CVD (PECVD): This is a pivotal variant. PECVD uses an electric field to generate a plasma (an ionized gas), which provides the energy for the chemical reaction. This allows the deposition to occur at much lower temperatures, making it suitable for substrates that cannot withstand traditional CVD heat.

- Laser-Assisted (LCVD) & Photo-Assisted CVD (PACVD): These highly specialized methods use a focused energy source—a laser or ultraviolet light—to initiate the reaction. Their key advantage is the ability to deposit a coating onto a very specific, targeted area of the substrate.

Understanding the Trade-offs of Traditional CVD

While powerful, the conventional high-temperature CVD process has significant limitations that drive the need for the variants described above.

The High-Temperature Limitation

Standard CVD processes operate at very high temperatures, often between 800°C and 1000°C. This restricts its use to substrates that can withstand such heat without deforming or melting, such as cemented carbides.

Risk of Cracking and Peeling

Because the coating is applied at a high temperature, significant tensile stress can build up as the part cools down. This can lead to fine cracks in the coating, which may cause it to peel or flake off under external impact or stress.

Unsuitability for Interrupted Processes

This risk of cracking makes traditional CVD less suitable for tools used in interrupted cutting applications, such as milling. The constant, non-uniform impact can exploit the micro-cracks and cause premature coating failure.

Making the Right Choice for Your Goal

Selecting the correct CVD process requires aligning the method's capabilities with your material's limitations and your product's performance needs.

- If your primary focus is extreme hardness on a temperature-resistant substrate: Traditional high-temperature LPCVD is often the most robust and cost-effective choice.

- If your primary focus is coating a temperature-sensitive material like an alloy or polymer: Plasma-Enhanced CVD (PECVD) is the necessary alternative, as it operates at significantly lower temperatures.

- If your primary focus is depositing a film on a very specific, targeted area: Laser-Assisted CVD (LCVD) provides the highest degree of spatial control for precision applications.

Understanding these fundamental process variations is the key to selecting the ideal coating strategy for your specific material and performance goals.

Summary Table:

| CVD Type | Acronym | Key Feature | Ideal For |

|---|---|---|---|

| Atmospheric Pressure CVD | APCVD | Operates at normal pressure | Fast, simple deposition |

| Low-Pressure CVD | LPCVD | Vacuum environment for high purity | Excellent uniformity on complex shapes |

| Plasma-Enhanced CVD | PECVD | Uses plasma for low-temperature deposition | Temperature-sensitive substrates (alloys, polymers) |

| Laser-Assisted CVD | LCVD | Focused energy for precise targeting | High-precision, localized coating applications |

Ready to select the perfect CVD coating process for your lab's materials?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including advanced CVD systems tailored to your specific research and production needs. Whether you require the high-temperature robustness of LPCVD or the precision of PECVD for sensitive substrates, our experts are here to help you achieve superior coating results.

Contact us today to discuss your application and discover how our solutions can enhance your laboratory's capabilities. Get in touch now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is CVD used for in semiconductor? Building the Microscopic Layers of Modern Chips

- Why does the growth of additional graphene layers typically not occur? Unlock Self-Limiting Synthesis Secrets

- What is the role of a high-frequency induction power supply in a CVD system? Powering ZrC Growth at 1600°C+

- What are the advantages and disadvantages of sputtering techniques? Achieve Superior Thin-Film Deposition

- What are the steps in chemical vapor deposition? A Guide to Controlled Thin-Film Synthesis

- Why is chemical vapor deposition important? Unlock Atomic-Level Precision for Your Materials

- What is a major disadvantage of the Chemical Vapor Deposition (CVD) process? Overcoming Safety and Thermal Challenges

- How does a CVD reactor work? Master the Science of High-Performance Thin Film Deposition