In short, there are no safe, reliable, or commonly available household substitutes for a proper crucible to melt gold. The extreme temperatures and material stresses involved mean that attempting to use an improper container is not a clever shortcut but a direct path to catastrophic failure, severe burns, and financial loss. A crucible is a piece of purpose-built safety equipment, not just a simple container.

The core issue is not finding another "bowl" that can hold hot things, but finding a material engineered to withstand the triple threat of extreme heat (over 1948°F / 1064°C), sudden temperature changes (thermal shock), and chemical interaction with molten metal. Anything less than a purpose-made crucible will fail.

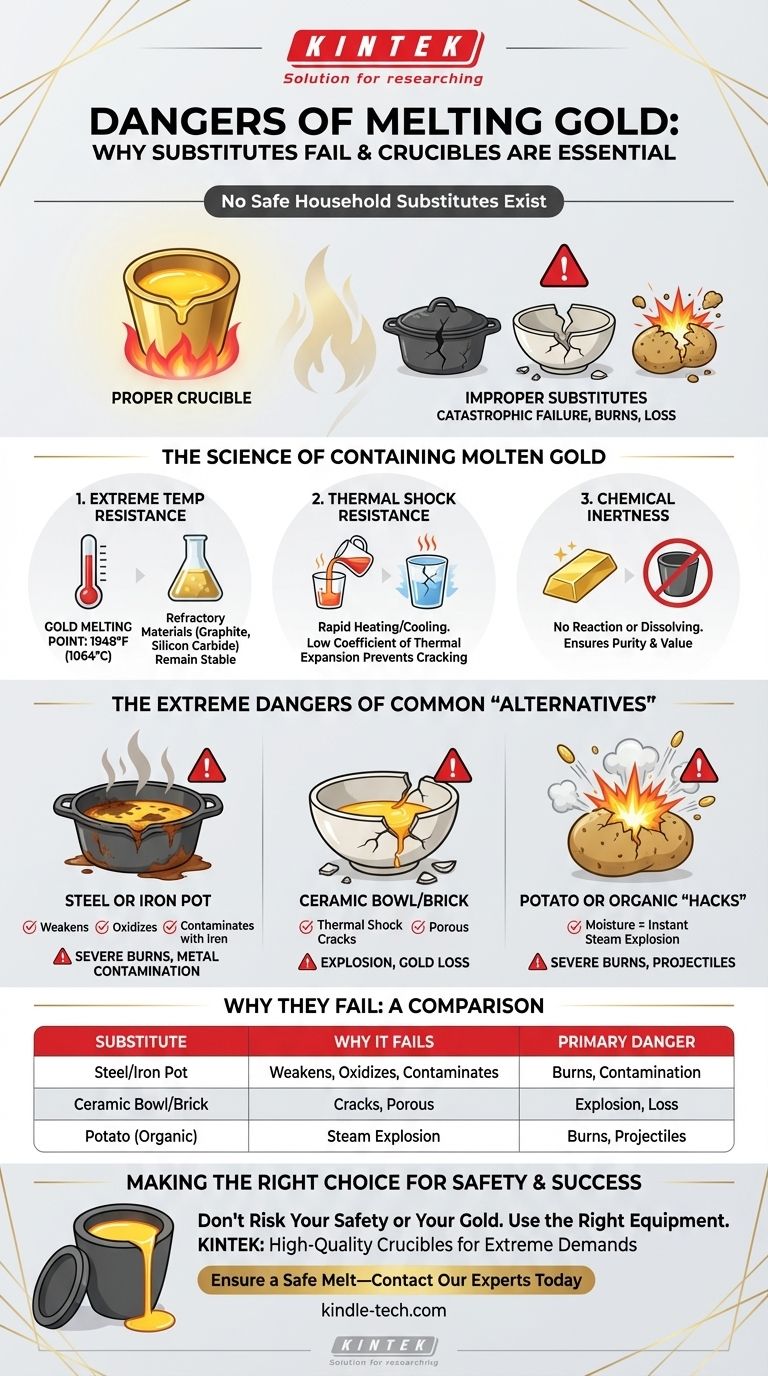

The Science of Containing Molten Gold

To understand why substitutes fail, you must first understand the intense demands placed on the container. Melting gold is a materials science problem, and a crucible is the engineered solution.

Requirement 1: Extreme Temperature Resistance

Gold has a melting point of 1948°F (1064°C). This temperature is far beyond the service limit of almost any common material.

A professional crucible is made from refractory materials, which are specifically designed to remain physically and chemically stable at exceptionally high temperatures.

Requirement 2: Thermal Shock Resistance

Pouring molten gold into a room-temperature container or heating a container rapidly creates immense internal stress. This is called thermal shock.

Crucibles made from materials like graphite or silicon carbide have a very low coefficient of thermal expansion. This allows them to heat and cool rapidly without cracking or shattering, a property everyday materials lack.

Requirement 3: Chemical Inertness

The container must not react with or dissolve into the molten gold. Any reaction will contaminate your gold, lowering its purity and value.

Graphite and ceramic crucibles are chemically inert, ensuring the purity of the metal you are working with.

The Extreme Dangers of Common 'Alternatives'

People often consider items they have on hand. Let's analyze why these are exceptionally dangerous and will not work.

Why a Steel or Iron Pot Will Fail

A common misconception is that a thick cast iron or steel pot can work. This is incorrect and dangerous.

While the melting point of steel is higher than gold, it will weaken dramatically, oxidize rapidly, and become brittle long before you reach gold's melting temperature. Worse, it will contaminate your gold with iron, rendering it impure.

Why Ceramic Bowls or Bricks Will Fail

Standard ceramics, like a kitchen bowl or a common brick, are not designed for metallurgical temperatures.

They will crack and explode from thermal shock. They are also porous, and the molten gold can seep into the pores, causing the container to fail violently while also trapping your valuable metal.

Why a Potato or Organic "Hacks" Will Fail

Internet folklore sometimes suggests using a hollowed-out potato. This is a myth that will lead to disaster.

The moisture inside the potato will turn to steam instantly upon contact with molten metal, causing a steam explosion. This will spray molten gold in all directions, guaranteeing severe burns and a total loss of your material.

Making the Right Choice for Your Goal

Your goal is to melt gold, but the implied, deeper goal is to do it successfully and safely. Using an improvised container makes both of these goals impossible. The only correct path is to acquire the proper safety equipment.

- If your primary focus is safety and success: Purchase a crucible made from graphite, silicon carbide, or a clay-graphite composite. They are designed specifically for this task and are the only professional choice.

- If your primary focus is a small, one-time melt: Even for a small amount, the physics do not change. Small, affordable graphite crucibles are widely available online and from jewelry supply stores. Do not compromise on safety.

- If your primary focus is cost savings: The cost of a proper crucible (often $20-$50) is insignificant compared to the value of the gold you are melting and the immense cost of a trip to the emergency room for severe burns.

Investing in the correct equipment is the only path to a successful and safe outcome.

Summary Table:

| Common Substitute | Why It Fails | Primary Danger |

|---|---|---|

| Steel or Iron Pot | Weakens, oxidizes, and contaminates gold | Severe burns, metal contamination |

| Ceramic Bowl/Brick | Cracks from thermal shock, is porous | Explosion, gold loss |

| Potato (Organic) | Moisture causes instant steam explosion | Severe burns, projectiles |

Don't risk your safety or your gold. Use the right equipment for the job.

KINTEK specializes in high-quality lab equipment and consumables, including crucibles designed specifically for the extreme demands of melting precious metals like gold. Our graphite and silicon carbide crucibles provide the necessary temperature resistance, thermal shock resistance, and chemical inertness for safe, successful, and pure results.

Ensure a safe and successful melt—contact our experts today to find the perfect crucible for your laboratory needs.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- How is sputtering done? A Step-by-Step Guide to Thin Film Deposition

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- What is the difference between VAR and ESR? A Guide to Understanding Tail Risk in Financial Modeling

- What are five applications of soldering? From Electronics to Art, Master Material Joining