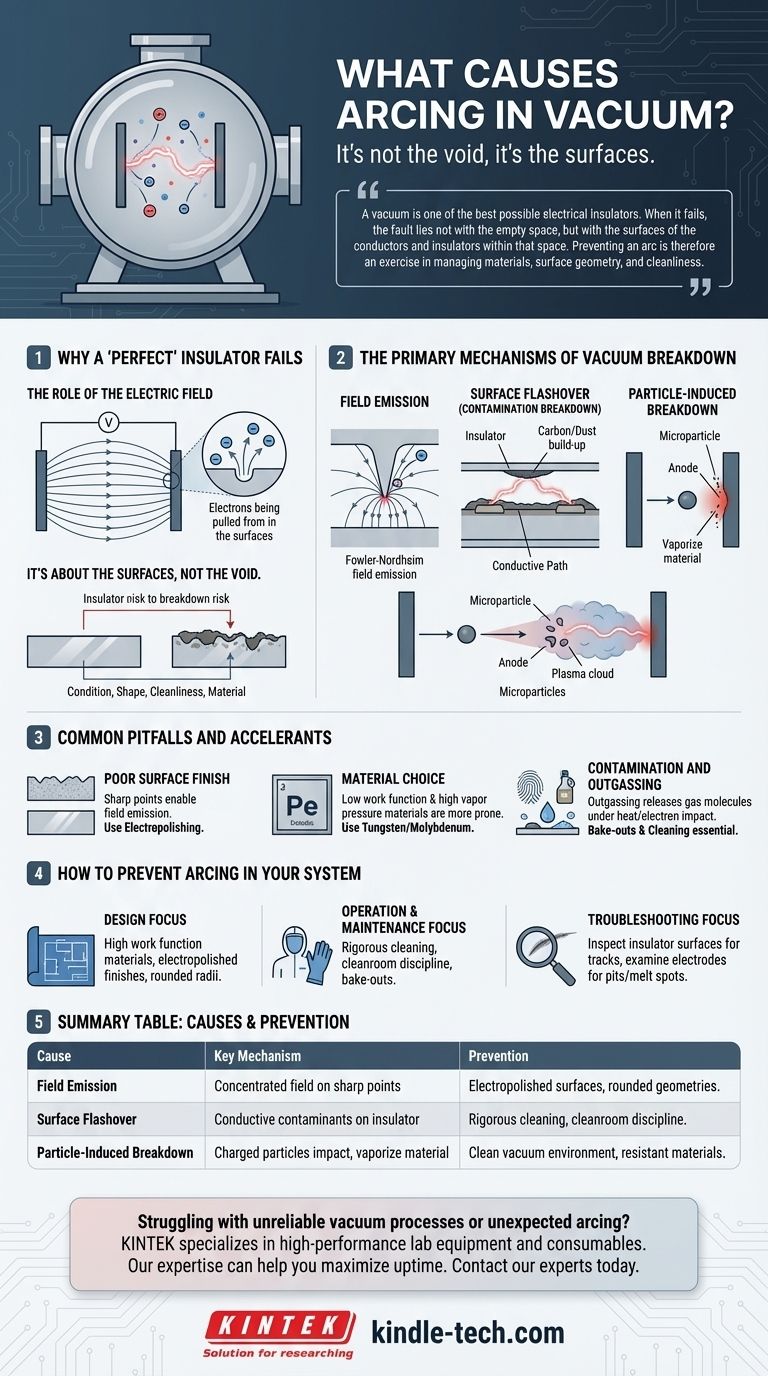

At its core, arcing in a vacuum is caused by the release and subsequent acceleration of charged particles between two surfaces, even without a gas to conduct them. This breakdown is not a failure of the vacuum itself, but rather a failure initiated by the materials within it, typically triggered by a combination of intense electric fields, microscopic surface imperfections, or contaminants on insulators.

A vacuum is one of the best possible electrical insulators. When it fails, the fault lies not with the empty space, but with the surfaces of the conductors and insulators within that space. Preventing an arc is therefore an exercise in managing materials, surface geometry, and cleanliness.

Why a "Perfect" Insulator Fails

A common misconception is that a perfect vacuum cannot conduct electricity. While it lacks a medium like air, the components inside the vacuum chamber—electrodes, insulators, and the chamber walls—are the source of the problem.

The Role of the Electric Field

A strong electric field is the primary driver of a vacuum arc. This field, measured in volts per meter, exerts a powerful force on charged particles.

When the voltage between two conductors becomes high enough, this force can physically pull electrons directly out of the atoms of the conductor's surface.

It's About the Surfaces, Not the Void

The vacuum itself is passive. The entire event unfolds on the surfaces of the materials under electrical stress.

The condition, shape, cleanliness, and type of material used for conductors and insulators are what determine the voltage at which a breakdown will occur.

The Primary Mechanisms of Vacuum Breakdown

Vacuum arcing is not a single event but a process that can be triggered by several distinct mechanisms. In practice, they often work in concert.

Field Emission

This is the most fundamental cause of vacuum breakdown. Even a highly polished metal surface has microscopic sharp points.

These microscopic points concentrate the electric field, dramatically increasing the local electrical force. This intense local field can pull electrons from the metal surface, a phenomenon known as Fowler-Nordheim field emission.

Once freed, these electrons are accelerated by the field, striking the opposing surface and potentially creating a cascading arc.

Surface Flashover (Contamination Breakdown)

Insulators are used to separate high-voltage conductors. However, the surface of an insulator is often the weakest point in a high-voltage vacuum system.

As noted in industrial settings like vacuum furnaces, conductive materials like carbon or metallic dust can build up on an insulator's surface. This contamination creates a conductive path, allowing a current to "flash over" the insulator and cause a short circuit.

This is a gradual degradation that can lead to catastrophic failure, as a small initial arc can vaporize more material, creating an even better conductive path for the next event.

Particle-Induced Breakdown

Microscopic particles (or "microparticles") of dust or metal can exist within the vacuum, either from contamination or by breaking off an electrode.

These particles can become charged and are then accelerated by the electric field. When a high-velocity particle strikes an electrode surface, the impact energy is sufficient to vaporize a small amount of material, creating a localized puff of gas and plasma that can immediately trigger a full-scale arc.

Common Pitfalls and Accelerants

Preventing arcing requires understanding the factors that make it more likely. These are not trade-offs but rather critical variables that must be controlled.

Poor Surface Finish

A rough or machined surface is covered in the microscopic sharp points that enable field emission. Electropolishing or other advanced finishing techniques are used to create a smoother, more rounded surface profile, significantly increasing the voltage the system can withstand.

Material Choice

Materials with a low work function (the energy needed to free an electron) and a high vapor pressure are more prone to arcing. Materials like tungsten and molybdenum are often chosen for high-voltage vacuum components due to their resilience.

Contamination and Outgassing

Fingerprints, oils, cleaning residues, and atmospheric water adsorbed onto surfaces can dramatically lower the breakdown voltage. When heated or struck by electrons, these contaminants outgas, releasing gas molecules that are easily ionized and provide fuel for an arc. This is why meticulous cleaning and high-temperature "bake-outs" are standard procedures.

How to Prevent Arcing in Your System

Your strategy for preventing arcing depends on your primary responsibility, whether it's designing the system, operating it, or troubleshooting it after a failure.

- If your primary focus is design: Specify materials with high work functions, mandate smooth electropolished surface finishes, and design components with large, rounded radii to minimize electric field concentration.

- If your primary focus is operation and maintenance: Implement rigorous cleaning protocols, ensure components are handled with cleanroom discipline, and perform bake-outs to drive off volatile contaminants before applying high voltage.

- If your primary focus is troubleshooting a failure: Meticulously inspect insulator surfaces for evidence of contamination tracks or flashover paths and examine electrode surfaces under magnification for pits or melted spots that indicate the origin point of an arc.

Ultimately, achieving a reliable high-voltage vacuum system is a discipline of controlling the material surfaces within it.

Summary Table:

| Cause of Arcing | Key Mechanism | Prevention Strategy |

|---|---|---|

| Field Emission | Electric field concentrates on sharp points, pulling electrons from metal surfaces. | Use electropolished surfaces and rounded geometries to minimize field concentration. |

| Surface Flashover | Conductive contaminants (e.g., carbon dust) create a path for current over an insulator. | Implement rigorous cleaning protocols and handle components with cleanroom discipline. |

| Particle-Induced Breakdown | Charged dust or metal particles impact surfaces, vaporizing material and creating plasma. | Ensure a clean vacuum environment and use materials resistant to particle generation. |

Struggling with unreliable vacuum processes or unexpected arcing? KINTEK specializes in high-performance lab equipment and consumables designed for demanding environments. Our expertise in material science and vacuum system design can help you select the right components and establish maintenance protocols to maximize uptime and prevent costly failures. Contact our experts today to discuss how we can enhance the reliability and performance of your laboratory systems.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of using high-temperature vacuum furnaces for annealing titanium dioxide? Optimize Bioactivity

- How does a high-temperature annealing furnace facilitate the homogenization of high-entropy alloys and stainless steels?

- What environmental protection do mechanical vacuum pump sets provide during zirconium alloy melting? Prevent Embrittlement

- What is the tightness rate of a leak? Quantify Your Seal's Performance

- What is the temperature range of an arc furnace? Mastering High-Temp Steel Production

- How does a precision furnace affect 316LN phase transformation? Control Sigma Phase & Prevent Micro-Cracks

- What is vacuum hardening? Achieve Superior Surface Quality and Hardness

- Why is a laboratory vacuum drying oven recommended for rice straw residues? Protect Your Biomass Integrity