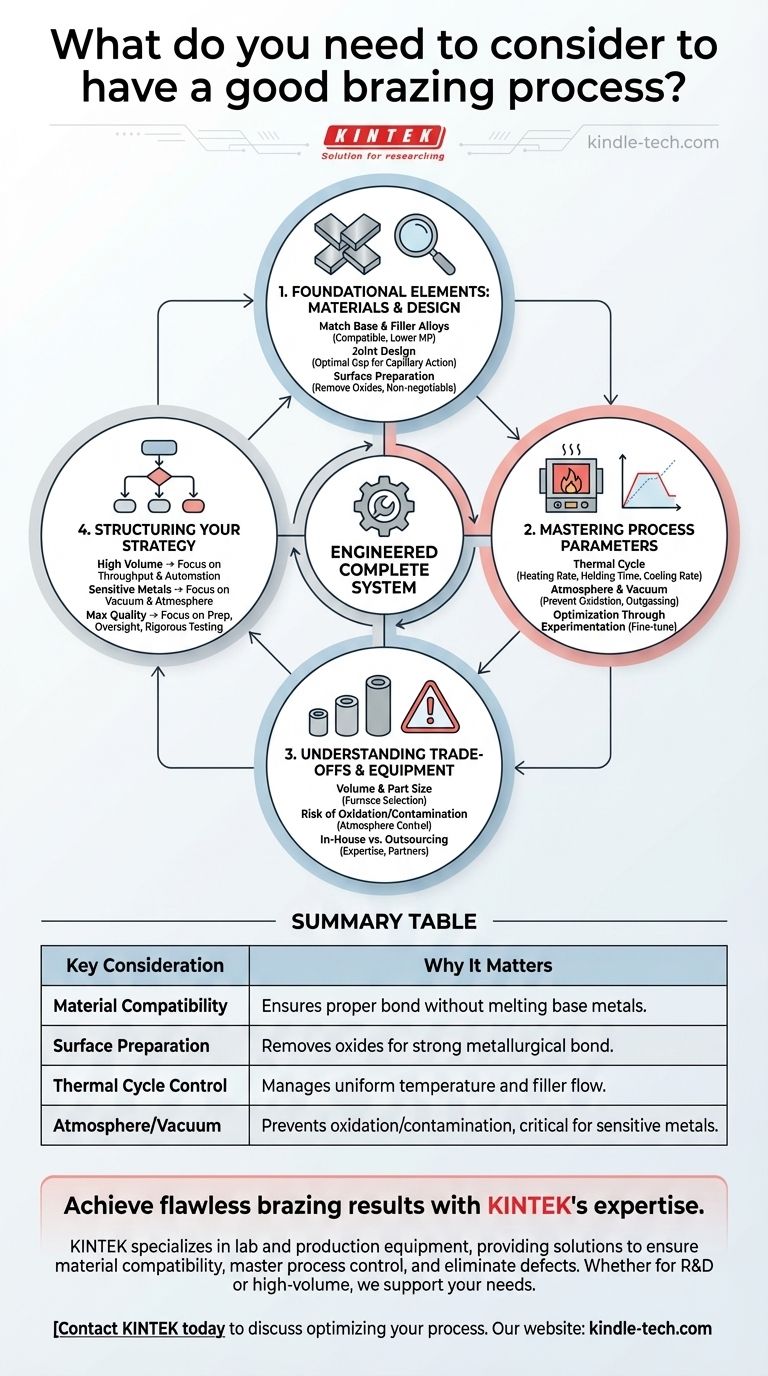

To achieve a good brazing process, you must systematically control four key areas: the compatibility of your base metals and filler alloy, meticulous surface preparation to remove oxides, precise management of the thermal cycle (heating, holding, and cooling), and the selection of the correct equipment and atmosphere for the job. These factors are not independent; they form an interconnected system that dictates the final quality of the joint.

The core principle of successful brazing is not finding a single "correct" setting, but rather engineering a complete system where the materials, joint design, surface condition, and process parameters are all perfectly aligned with the specific application and required outcome.

Foundational Elements: Materials and Design

Before the heat is ever applied, crucial decisions about materials and preparation set the stage for success or failure. Overlooking this phase is a common source of brazing defects.

### Matching Base Metals and Filler Alloys

The first step is ensuring the chosen filler alloy is chemically compatible with the base metals you intend to join.

The filler's melting point must be lower than that of the base metals, allowing it to flow into the joint via capillary action without melting the parent components.

### The Critical Role of Joint Design

The shape and size of the parts being joined directly influence how heat is absorbed and how the filler metal flows.

A well-designed joint provides the ideal gap for capillary action to draw the molten filler in, creating a strong, complete bond.

### Surface Preparation: The Non-Negotiable First Step

Nearly all metals have a surface oxide film that will prevent the filler alloy from wetting and bonding to the base material.

This layer must be removed, typically through chemical cleaning with an alkali solution or other mechanical methods, to ensure a strong metallurgical bond can form.

Mastering the Process Parameters

The actual brazing cycle is a delicate balance of temperature, time, and atmosphere. Each variable must be carefully controlled to match the materials and equipment.

### Controlling the Thermal Cycle

The thermal cycle consists of the heating rate, holding time at brazing temperature, and the cooling rate.

A proper heating rate ensures uniform temperature across the assembly. The holding time must be long enough for the filler to melt and flow completely, while the cooling rate can affect the final microstructure and strength of the joint.

### The Importance of Atmosphere and Vacuum

Many materials are highly sensitive to oxygen at elevated temperatures, which can lead to oxidation and a failed joint.

Brazing is therefore often performed in a controlled atmosphere or a high vacuum level. The choice depends on the material's sensitivity to oxidation and the potential for outgassing elements from the metal itself.

### Optimization Through Experimentation

While principles are universal, the ideal combination of these parameters varies for every unique application.

It is essential to determine the optimal process through experimental testing and screening to fine-tune the parameters for your specific parts and quality requirements.

Understanding the Trade-offs and Equipment

The equipment you choose and your operational strategy create constraints and opportunities. Understanding these trade-offs is key to a robust and cost-effective process.

### Evaluating Production Volume and Part Size

The required throughput and the physical size of your parts are primary drivers in furnace selection.

A small, high-value aerospace component has vastly different equipment needs than thousands of consumer-grade parts, influencing everything from furnace type to the level of automation.

### The Risk of Oxidation and Contamination

The single greatest risk in many brazing operations is contamination, primarily from oxygen.

Failing to select a furnace capable of maintaining the required atmosphere or vacuum for your specific material will consistently produce weak, unreliable joints.

### In-House Expertise vs. Outsourcing

Executing a high-quality brazing process requires significant metallurgical expertise.

If this expertise is not available internally, partnering with a certified metal treatment company is often the most reliable path. A proven track record and proper equipment are vital considerations when choosing a vendor.

How to Structure Your Brazing Strategy

Your primary goal should dictate your operational focus. Use these points to align your strategy with your desired outcome.

- If your primary focus is high-volume production: Prioritize equipment selection based on throughput, automation, and how the furnace integrates into your overall manufacturing flow.

- If your primary focus is joining sensitive or reactive metals: Concentrate on achieving the necessary vacuum level and atmosphere control to prevent oxidation and outgassing.

- If your primary focus is achieving maximum joint quality and reliability: Invest heavily in meticulous surface preparation, expert metallurgical oversight, and rigorous experimental process optimization.

Ultimately, a successful brazing operation is a repeatable, highly controlled scientific process, not an art form.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Material Compatibility | Ensures the filler alloy properly bonds with the base metals without melting them. |

| Surface Preparation | Removes oxides for a strong metallurgical bond; the most common cause of failure. |

| Thermal Cycle Control | Manages heating, holding, and cooling for uniform temperature and proper filler flow. |

| Atmosphere/Vacuum | Prevents oxidation and contamination, which is critical for sensitive or reactive metals. |

Achieve flawless brazing results with KINTEK's expertise.

A successful brazing process requires precise control and the right equipment. KINTEK specializes in lab and production equipment, including brazing solutions, to help you:

- Ensure Material Compatibility: Get expert guidance on selecting the right filler alloys for your base metals.

- Master Process Control: Utilize equipment designed for precise thermal and atmosphere management.

- Eliminate Defects: Achieve strong, reliable joints through proven methodologies and reliable machinery.

Whether you're in R&D or high-volume production, we provide the tools and support for your specific laboratory and manufacturing needs.

Contact KINTEK today to discuss how we can optimize your brazing process for superior quality and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is oxidation in brazing? How to prevent it for strong, durable joints