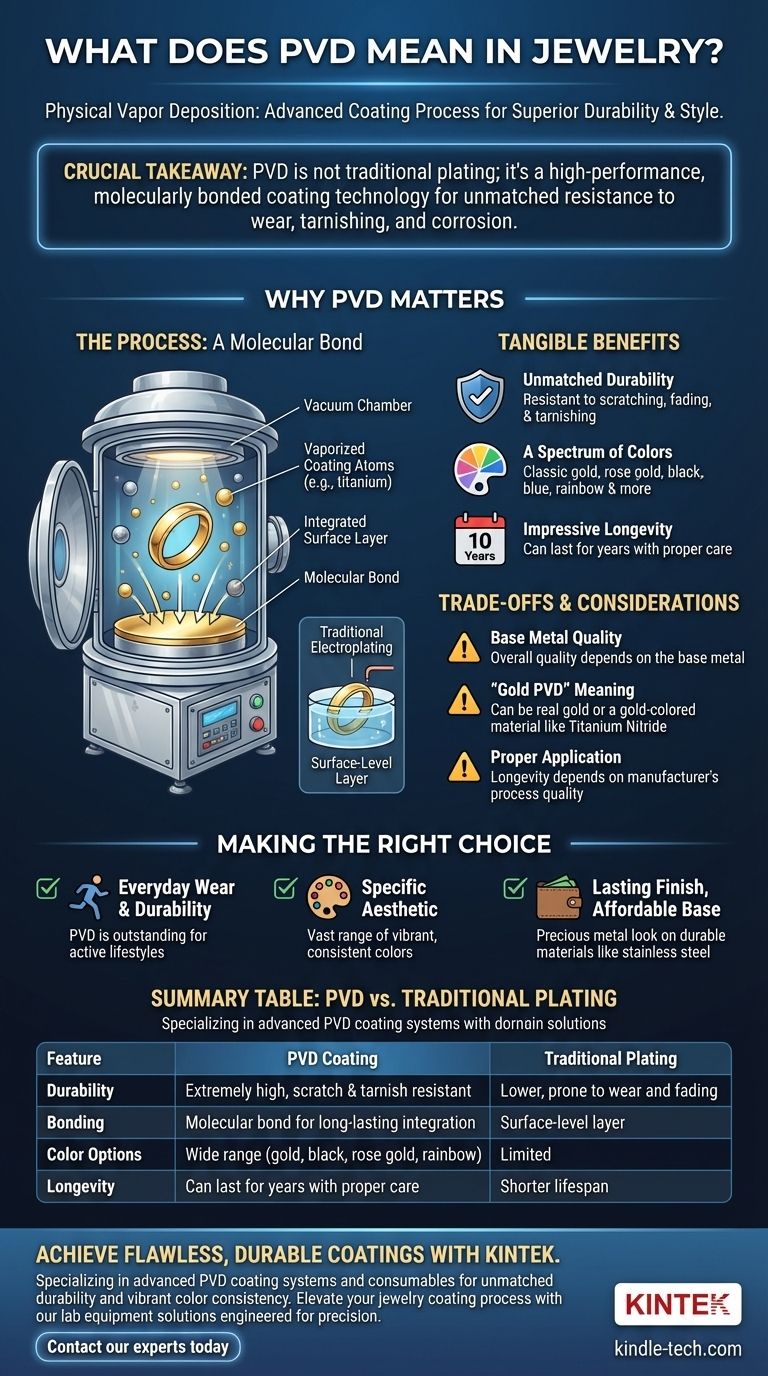

In the world of jewelry, PVD stands for Physical Vapor Deposition. It is an advanced coating process that molecularly bonds a thin but extremely durable layer of metal onto a base material, such as stainless steel. This technique is used to create long-lasting, wear-resistant finishes in a wide variety of colors, from classic gold tones to vibrant rainbow effects.

The crucial takeaway is that PVD is not traditional plating; it's a high-performance coating technology. Its primary advantage is creating a finish that is significantly more durable and resistant to scratches, tarnishing, and corrosion than conventional methods.

Why PVD Matters for Your Jewelry

To understand the value of PVD, it’s essential to see it as more than just a color application. It's a technical process that fundamentally enhances the properties of the jewelry piece itself.

The Process: A Molecular Bond

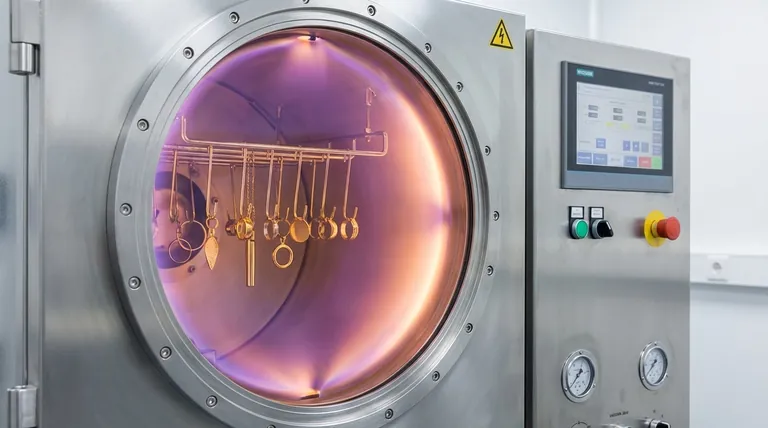

Unlike traditional electroplating, which essentially "dips" a piece of jewelry in a solution to add a thin top layer, PVD occurs in a high-tech vacuum chamber.

The coating material (such as gold or titanium) is vaporized into its atomic components. These atoms are then deposited onto the jewelry, forming a new, integrated surface layer.

This creates a true molecular bond between the coating and the base metal. The result isn't just a layer sitting on top; it's a finish that has become part of the item itself.

The Tangible Benefits

This advanced process translates directly into superior performance for everyday wear.

Unmatched Durability

The atomic bond created during the PVD process ensures the coating is highly resistant to fading, scratching, and tarnishing. This makes PVD-coated jewelry an excellent choice for items you wear daily.

A Spectrum of Colors

PVD technology allows for a much wider array of stable color options than precious metals alone. This includes classic gold and silver tones, as well as modern rose gold, black, blue, and even iridescent rainbow finishes.

Impressive Longevity

A properly applied PVD coating can last for years, with some manufacturers citing up to 10 years of life with proper care. It creates a thick, resilient layer that stands up to the rigors of daily life.

Understanding the Trade-offs and Considerations

While PVD is a superior technology, it's important to approach it with a clear understanding of what it is and what it isn't.

Base Metal Quality is Key

The PVD coating is incredibly durable, but the overall quality of the jewelry still depends on the base metal. A strong PVD finish on a poorly made, flimsy base will not save the piece from bending or breaking.

"Gold PVD" Can Mean Two Things

A "gold PVD" finish can refer to a layer of actual gold being bonded to the base material. However, it can also refer to a gold-colored, non-gold material (like Titanium Nitride) being used to create the look. Both are durable, but if having real gold is important to you, verify the specific material used in the coating.

Proper Application is Crucial

The longevity of a PVD finish is heavily dependent on the quality of the manufacturer's application process. A rushed or poorly executed PVD coating will not deliver the promised durability. Stick to reputable brands known for high-quality manufacturing.

Making the Right Choice for Your Goal

Understanding PVD helps you select jewelry that aligns with your specific needs.

- If your primary focus is everyday wear and durability: PVD is an outstanding choice, offering superior resistance to the scratches and scuffs of an active lifestyle.

- If your primary focus is achieving a specific aesthetic: PVD provides access to a vast range of vibrant, consistent colors that are difficult or impossible to achieve with traditional metals.

- If your primary focus is a lasting finish on an affordable base: PVD allows you to enjoy the look of precious metals on durable and cost-effective materials like stainless steel, without the fear of rapid tarnishing or fading.

Ultimately, choosing PVD-coated jewelry is choosing a piece engineered for modern life and built to retain its beauty through wear.

Summary Table:

| Feature | PVD Coating | Traditional Plating |

|---|---|---|

| Durability | Extremely high, scratch & tarnish resistant | Lower, prone to wear and fading |

| Bonding | Molecular bond for long-lasting integration | Surface-level layer |

| Color Options | Wide range (gold, black, rose gold, rainbow) | Limited |

| Longevity | Can last for years with proper care | Shorter lifespan |

Ready to achieve flawless, durable coatings for your jewelry products? At KINTEK, we specialize in advanced PVD coating systems and consumables that deliver unmatched durability and vibrant color consistency. Whether you're a jewelry manufacturer looking to enhance product quality or a designer seeking innovative finishes, our lab equipment solutions are engineered for precision and performance. Contact our experts today to discover how KINTEK can elevate your jewelry coating process!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process