Selecting the right oil-free diaphragm pump is a critical decision that hinges on three primary factors: the ultimate vacuum level your process requires, the pumping speed (flow rate) needed to perform the work in an acceptable time, and the chemical compatibility of the pump's materials with the gases or vapors you intend to handle. These elements, balanced against your budget, will dictate the success and longevity of your vacuum system.

The most common mistake is choosing a pump based on a single specification like "maximum vacuum" or "price." A successful selection requires a holistic approach, matching the pump's entire performance curve and material resilience to the specific demands of your application.

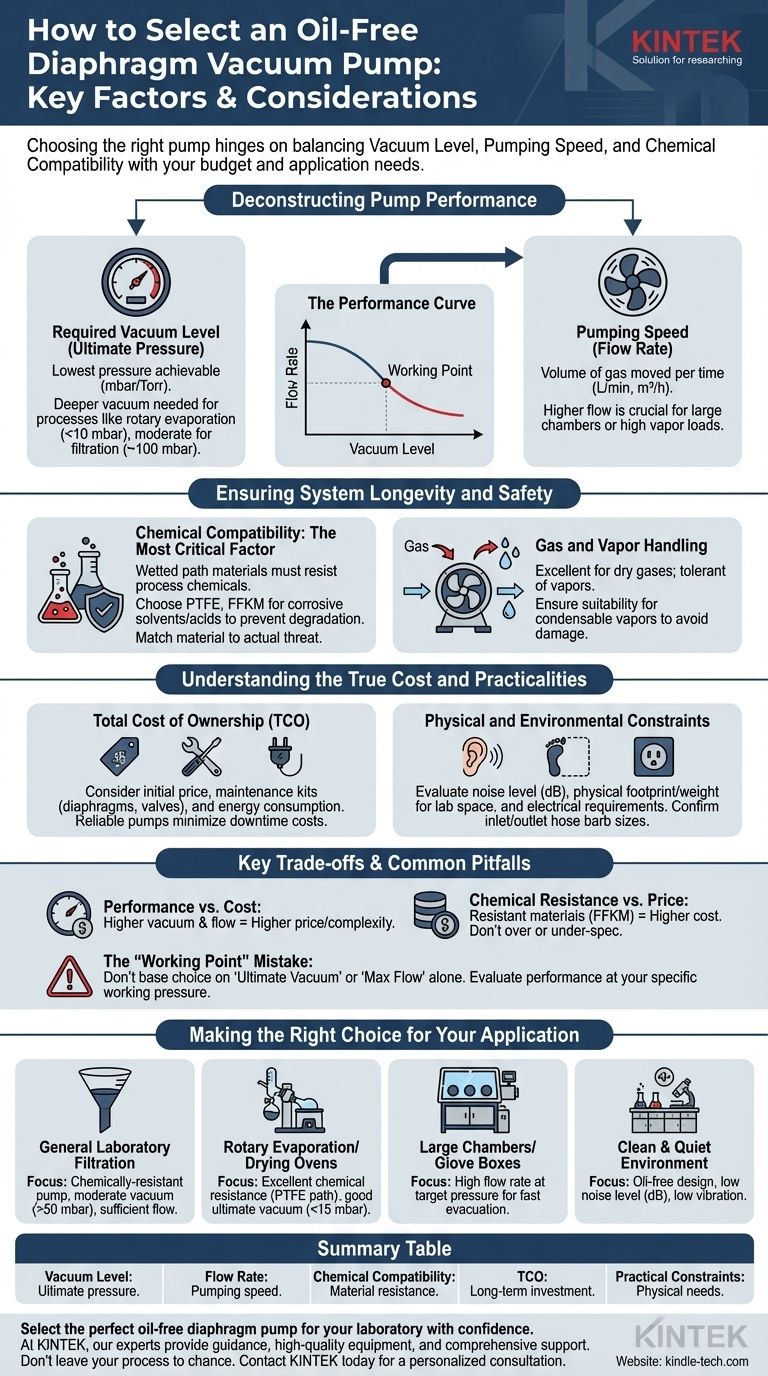

Deconstructing Pump Performance

Choosing a pump begins with understanding its two fundamental performance metrics. These specifications are not independent; they exist in a dynamic relationship that defines the pump's true capabilities.

Required Vacuum Level (Ultimate Pressure)

The ultimate vacuum is the lowest pressure the pump can achieve under ideal conditions, typically measured in millibars (mbar) or Torr. This number tells you the "depth" of vacuum possible.

Different applications have vastly different requirements. Simple filtration may only need a moderate vacuum (e.g., 100 mbar), while rotary evaporation of high-boiling-point solvents demands a much deeper vacuum (e.g., <10 mbar).

Pumping Speed (Flow Rate)

Flow rate, or pumping speed, measures the volume of gas the pump can move per unit of time (e.g., liters per minute or cubic meters per hour). This determines how quickly the pump can evacuate a chamber or handle a continuous gas load.

A larger process chamber or a process that generates a high volume of vapor requires a higher flow rate to complete the task efficiently.

The Performance Curve: Where Vacuum Meets Flow

Crucially, a pump's maximum flow rate only occurs at atmospheric pressure. As the pump pulls a vacuum and the pressure inside the system drops, its effective flow rate decreases.

Every pump has a performance curve that plots its flow rate against the vacuum level. Your goal is to find a pump whose curve provides sufficient flow at your specific working pressure—the vacuum level at which your process actually runs.

Ensuring System Longevity and Safety

A pump that performs well on day one is useless if it fails prematurely due to incompatibility. For diaphragm pumps, material selection is paramount.

Chemical Compatibility: The Most Critical Factor

Oil-free diaphragm pumps expose their internal "wetted path" components—the diaphragms, valves, and pump heads—directly to the process gas. If these materials are not resistant to the chemicals being pumped, they will quickly degrade, leading to pump failure.

Ensure the pump you choose has wetted parts made from materials like PTFE, FFKM, or other fluoropolymers if you are handling any corrosive solvents or acidic vapors. Under-specifying chemical resistance is the most common cause of premature failure.

Gas and Vapor Handling

Diaphragm pumps are excellent at handling dry gases and are quite tolerant of vapors. However, allowing vapors to condense into liquid inside the pump can impair performance and cause damage over time.

For processes with high vapor loads, such as from a drying oven, ensure the pump's specifications confirm its suitability for condensable vapors.

Understanding the True Cost and Practicalities

The sticker price is only one part of the equation. A reliable technical advisor always considers the total investment over the pump's life.

Total Cost of Ownership (TCO)

Beyond the initial purchase price, consider the long-term costs. Diaphragms and valves are consumable parts that require periodic replacement. Factor in the cost and ease of obtaining a maintenance kit.

Also, consider energy consumption and the financial impact of potential downtime if a less reliable pump fails during a critical process.

Physical and Environmental Constraints

Practical considerations often guide the final choice. In a quiet laboratory, the noise level (dB) is a critical factor for user comfort.

Also, evaluate the pump's physical footprint and weight, ensuring it fits your available space. Finally, check the required electrical specifications (voltage, horsepower) to ensure compatibility with your facility.

Connectivity

Confirm the hose barb size on the pump's inlet and outlet matches your existing tubing and apparatus. Using adapters can work, but a direct fit is always preferable to minimize potential leaks.

Key Trade-offs and Common Pitfalls

Every engineering decision involves balancing competing factors. Being aware of these trade-offs is the mark of an informed professional.

Performance vs. Cost

There is a direct correlation between performance and price. Pumps capable of achieving deeper vacuum levels and higher flow rates are inherently more complex and expensive to manufacture.

Chemical Resistance vs. Price

The materials used for the wetted path are a major cost driver. A pump with standard NBR rubber diaphragms is much cheaper than one with highly resistant FFKM components. Do not over-spec or under-spec; match the material to the actual chemical threat.

The "Working Point" Mistake

Do not select a pump based solely on its "ultimate vacuum" or "max flow" listed on the box. A pump may have a great ultimate vacuum but a terrible flow rate at a moderate pressure, making it too slow for your process. Always evaluate performance at your target working pressure.

Making the Right Choice for Your Application

Use your specific process goal to prioritize these factors and guide your final selection.

- If your primary focus is general laboratory filtration: A basic, chemically-resistant pump with a moderate vacuum (>50 mbar) and flow rate is likely sufficient and cost-effective.

- If your primary focus is rotary evaporation or drying ovens: Prioritize excellent chemical resistance (e.g., PTFE path) and a good ultimate vacuum (<15 mbar) to handle various solvent vapors effectively.

- If your primary focus is evacuating large chambers or glove boxes: Prioritize a high flow rate at your target pressure to reduce evacuation times.

- If your primary focus is a clean and quiet environment: The oil-free design is your starting point, but pay close attention to the published noise level (dB) and vibration characteristics.

By systematically aligning these technical factors with your specific process needs, you can select a pump that delivers reliable, efficient, and cost-effective performance for years to come.

Summary Table:

| Factor | Key Consideration | Why It Matters |

|---|---|---|

| Vacuum Level | Ultimate pressure (mbar/Torr) required for your process. | Determines the "depth" of vacuum achievable. |

| Flow Rate | Pumping speed (L/min, m³/h) at your working pressure. | Dictates how quickly a chamber is evacuated. |

| Chemical Compatibility | Material resistance of wetted parts (e.g., PTFE, FFKM). | Prevents premature failure from corrosive vapors. |

| Total Cost of Ownership | Initial price, maintenance kit cost, and energy consumption. | Reflects the true long-term investment. |

| Practical Constraints | Noise level (dB), footprint, and inlet/outlet connections. | Ensures the pump fits your lab's physical and operational needs. |

Select the perfect oil-free diaphragm pump for your laboratory with confidence.

At KINTEK, we understand that every application—from rotary evaporation and filtration to glove box evacuation—has unique demands. Our experts are here to help you analyze your specific vacuum level, flow rate, and chemical compatibility requirements to recommend a pump that delivers optimal performance, longevity, and value.

We provide:

- Expert Guidance: Navigate performance curves and material selections to avoid common pitfalls.

- High-Quality Equipment: Reliable pumps designed for precise laboratory applications.

- Comprehensive Support: Ensure your investment is protected with accessible maintenance kits and consumables.

Don't leave your process to chance. Contact KINTEK today for a personalized consultation and ensure your vacuum system is a perfect match for your work.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the mechanism of Rotavapor? Efficient Solvent Removal at Low Temperatures Explained

- How does the pumping system contribute to TDS analysis? Achieve Precise UHV for High-Sensitivity Detection

- What critical role does a Laboratory Stirrer play during leaching? Enhance Titanium-Magnesium Waste Recovery

- What is the strength of a quartz tube? Withstand 1,000 PSI in High-Temp, High-Purity Applications

- Why use zirconia jars for sulfide electrolytes? Ensure Purity and High Performance in Solid-State Battery Research

- What does a vacuum switch do? Automate Control with Simple On/Off Signals

- Why is a capacitance manometer preferred for RF plasma systems? Ensure Precise Gas-Independent Pressure Monitoring

- Can you run a pellet stove without a vacuum switch? The Critical Safety Risks Explained