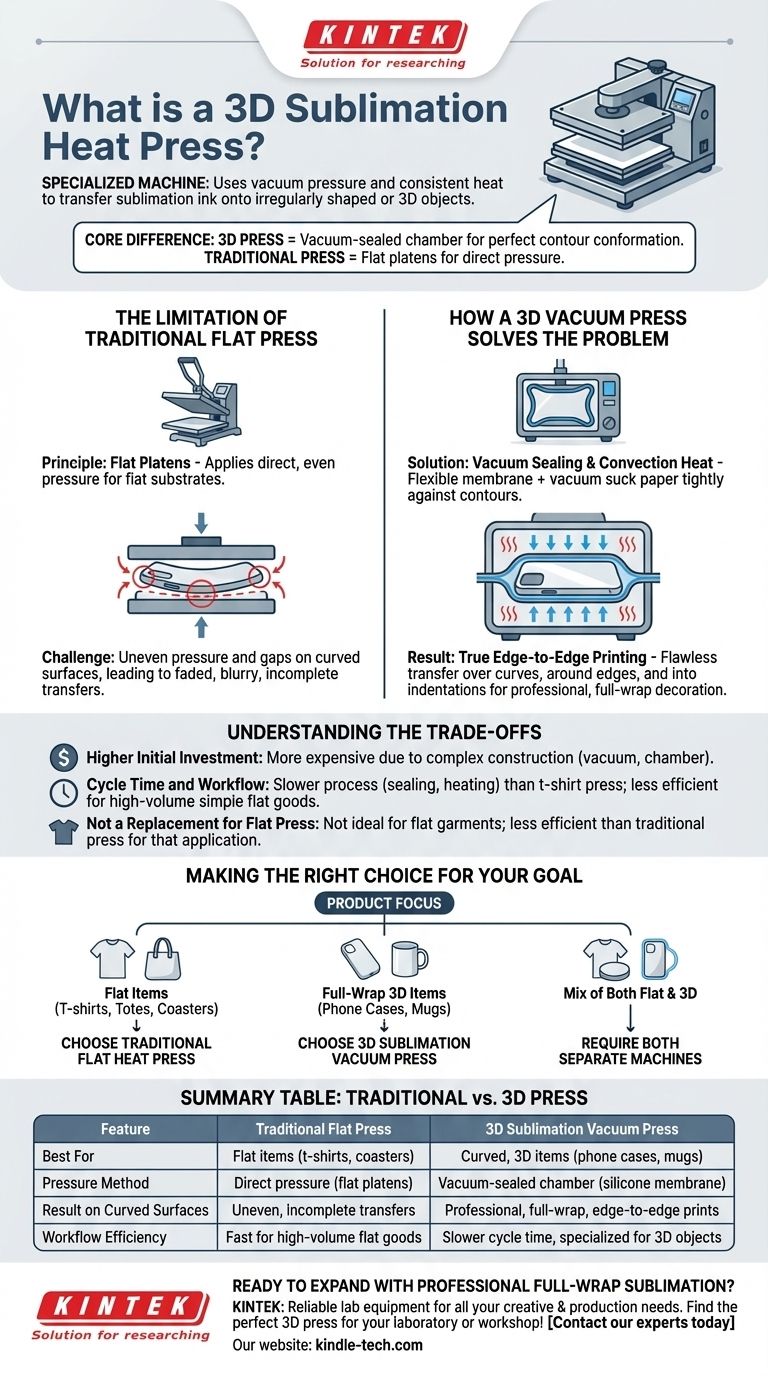

In essence, a 3D sublimation heat press is a specialized machine that uses vacuum pressure and consistent heat to transfer sublimation ink onto irregularly shaped or three-dimensional objects. Unlike a standard flat press designed for items like t-shirts, a 3D press can wrap a design around curves and into crevices, ensuring a complete, edge-to-edge transfer.

The core difference is how pressure is applied. A traditional press uses flat platens, making it unsuitable for curved surfaces. A 3D press uses a vacuum-sealed chamber, which forces a transfer sheet to conform perfectly to an object's unique shape.

The Limitation of a Traditional Flat Press

To understand the value of a 3D press, you must first recognize the fundamental constraint of a standard heat press.

The Principle of Flat Platens

A traditional heat press, whether a clamshell or swing-away design, operates with two flat surfaces called platens. It applies direct, even pressure and high temperature to transfer a design onto a flat substrate like a garment or a mousepad.

The Challenge with Curved Surfaces

When you try to use a flat press on a curved object, such as a phone case or mug, the platens cannot make uniform contact. This results in uneven pressure and gaps, leading to faded, blurry, or incomplete transfers, especially around the edges.

How a 3D Vacuum Press Solves the Problem

The 3D sublimation press was engineered specifically to overcome the challenge of three-dimensional surfaces. It abandons flat platens for a completely different mechanism.

From Direct Pressure to Vacuum Sealing

Instead of pressing an object between two plates, you place the item inside the 3D press, which functions more like a small oven. A flexible silicone membrane is placed over the object, and a built-in pump creates a vacuum, sucking the membrane and the attached sublimation paper tightly against every contour of the item.

The Power of Convection Heat

Once the vacuum is sealed, the machine heats the entire chamber. This convection heat evenly activates the sublimation ink across the entire surface area, turning the solid ink into a gas that permanently bonds with the polymer-coated substrate.

The Result: True Edge-to-Edge Printing

This combination of vacuum pressure and convection heat ensures the design transfers flawlessly over curves, around edges, and into indentations. The result is a professional, full-wrap decoration that is impossible to achieve with a flat press.

Understanding the Trade-offs

While powerful, a 3D vacuum press is a specialized tool with its own set of considerations.

Higher Initial Investment

3D sublimation presses are generally more expensive than entry-level flat presses due to their more complex construction, including the vacuum pump and oven-like chamber.

Cycle Time and Workflow

The process of arranging items, sealing the vacuum, and allowing the chamber to heat can be more time-consuming per item than working with a standard t-shirt press. This makes it less efficient for high-volume production of simple flat goods.

Not a Replacement for a Flat Press

A 3D press is not the ideal tool for flat garments like t-shirts. While you can press small, flat items inside, a traditional flat press is far more efficient and effective for that specific application.

Making the Right Choice for Your Goal

Selecting the correct equipment comes down to the products you want to create.

- If your primary focus is on flat items like t-shirts, tote bags, or coasters: A traditional flat heat press is the correct and most efficient tool for your work.

- If your primary focus is producing full-wrap designs on phone cases, mugs, or other curved items: A 3D sublimation vacuum press is essential to achieve professional, edge-to-edge results.

- If you plan to produce a mix of both flat apparel and 3D objects: You will likely need two separate machines, as each is a specialized tool optimized for a different type of product.

Ultimately, a 3D press empowers you to decorate objects that are simply beyond the reach of standard sublimation equipment.

Summary Table:

| Feature | Traditional Flat Press | 3D Sublimation Vacuum Press |

|---|---|---|

| Best For | Flat items (t-shirts, coasters) | Curved, 3D items (phone cases, mugs) |

| Pressure Method | Direct pressure from flat platens | Vacuum-sealed chamber with a silicone membrane |

| Result on Curved Surfaces | Uneven, incomplete transfers | Professional, full-wrap, edge-to-edge prints |

| Workflow Efficiency | Fast for high-volume flat goods | Slower cycle time, specialized for 3D objects |

Ready to expand your product line with professional, full-wrap sublimation?

At KINTEK, we specialize in providing reliable lab equipment and consumables for all your creative and production needs. Whether you're personalizing phone cases, mugs, or other 3D items, our expertise ensures you get the right equipment for flawless results.

Contact our experts today to find the perfect 3D sublimation heat press for your laboratory or workshop!

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hot press improve alloy performance? Optimize Liquid Phase Sintering for High-Strength Materials

- How does the pressure loading system of a laboratory hydraulic hot press affect Mo2Ga2C? Engineer Crystal Orientation

- What physical conditions do laboratory hot presses provide for nacre-like alumina? Optimize Sintering for High Density

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What is hot press laminate? A Durable, Non-Porous Surface Created by Heat and Pressure

- What is machine press plywood? The Key to Modern Plywood's Strength and Stability

- What's the difference between a heat press machine and an iron? Achieve Professional, Durable Apparel Transfers