A ceramic furnace is a high-temperature chamber used for processing a wide range of materials. Its primary function is to apply precise and often extreme heat—sometimes in a controlled atmosphere—to induce physical and chemical changes in a substance, such as sintering ceramic powders, annealing metals, or conducting high-temperature experiments.

The core purpose of a ceramic furnace is not merely to generate heat, but to provide a highly controlled thermal environment. This precision enables the transformation of raw materials into finished components with specific, engineered properties for industrial, scientific, and commercial applications.

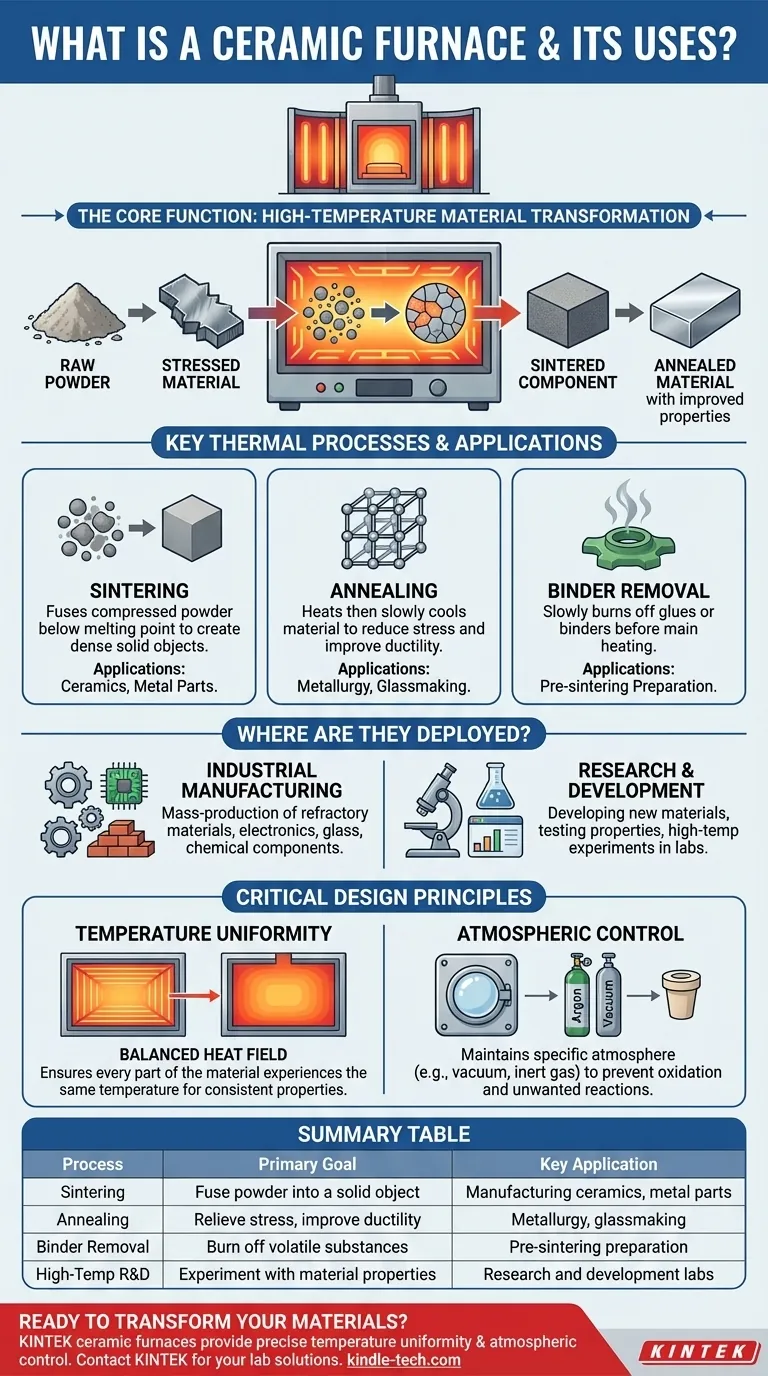

The Core Function: High-Temperature Material Transformation

A ceramic furnace is fundamentally a tool for changing a material's internal structure or composition. This is achieved through several key thermal processes.

Sintering and Firing

Sintering is one of the most common applications. It involves heating a compressed powder (like ceramic or metal) to a temperature below its melting point.

This process causes the particles to fuse, creating a dense, solid object. This is essential for manufacturing everything from ceramic components to certain metal parts.

Annealing and Heat Treatment

Annealing involves heating a material and then cooling it slowly. This process alters its microstructure to reduce hardness, relieve internal stresses, and improve ductility.

It's a critical step in metallurgy and glassmaking to make materials less brittle and easier to work with.

Roasting and Binder Removal

Many processes require the removal of binders, glues, or other volatile substances before the main heating stage.

A ceramic furnace can be programmed for a slow, initial heating ramp to safely burn off these materials, a process sometimes called "ceramic glue discharge" or binder burnout.

Where Ceramic Furnaces Are Deployed

The furnace's ability to handle diverse materials under precise conditions makes it essential across numerous fields. Its role can be broadly divided into two categories.

Industrial Manufacturing

In sectors like metallurgy, electronics, and building materials, furnaces are production workhorses.

They are used for mass-producing refractory materials, hardening machine parts, processing glass, and creating specialized components for the chemical industry.

Research and Development

In universities and scientific research institutes, ceramic furnaces are indispensable tools for experimentation.

Researchers use them to develop new materials, test the thermal properties of existing ones, and conduct high-temperature experiments under controlled atmospheric conditions.

Understanding Key Design Principles

The effectiveness of a ceramic furnace lies in its ability to maintain a stable and predictable environment at extreme temperatures.

The Need for Temperature Uniformity

For a material to be processed correctly, every part of it must experience the same temperature. A well-designed furnace creates a balanced temperature field.

Any significant temperature variations can lead to inconsistent properties, internal stresses, or complete failure of the part or experiment.

The Importance of Atmospheric Control

Many advanced material processes cannot occur in open air, as oxygen would cause unwanted reactions (oxidation).

These furnaces are often sealed to maintain a specific atmosphere, such as a vacuum, an inert gas like argon, or other reactive gases. Components like ceramic plugs are used to seal openings and protect temperature-sensitive parts like rubber O-rings, ensuring the internal atmosphere remains pure and contained.

Making the Right Choice for Your Goal

Selecting the right thermal process is dependent on your final objective.

- If your primary focus is creating a solid object from a powder: Your goal is sintering, which requires precise temperature control just below the material's melting point.

- If your primary focus is making a material less brittle or relieving internal stress: You need to perform an annealing cycle with a controlled heating and slow cooling phase.

- If your primary focus is experimenting with new materials at high temperatures: You need a furnace with excellent temperature uniformity and atmospheric control to ensure repeatable and accurate results.

Ultimately, a ceramic furnace is a foundational tool that allows us to engineer materials at a fundamental level.

Summary Table:

| Process | Primary Goal | Key Application |

|---|---|---|

| Sintering | Fuse powder into a solid object | Manufacturing ceramics, metal parts |

| Annealing | Relieve stress, improve ductility | Metallurgy, glassmaking |

| Binder Removal | Burn off volatile substances | Pre-sintering preparation |

| High-Temp R&D | Experiment with material properties | Research and development labs |

Ready to transform your materials with precision? A KINTEK ceramic furnace provides the controlled thermal environment essential for sintering, annealing, and advanced R&D. Our lab equipment ensures the temperature uniformity and atmospheric control your processes demand.

Contact KINTEK today to find the perfect furnace solution for your laboratory's specific needs in materials science and manufacturing.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance