At its core, a cold isostatic press (CIP) is a machine that uses high-pressure liquid to uniformly compress powdered material inside a flexible mold. It operates at or near room temperature to compact the powder into a solid, cohesive object known as a "green" part, which has enough strength to be handled before it undergoes a final strengthening process like sintering.

The fundamental purpose of cold isostatic pressing is to leverage uniform, liquid-based pressure to overcome the limitations of traditional mechanical pressing. This creates highly consistent, dense powder compacts, especially for parts with complex geometries, minimizing internal defects before final densification.

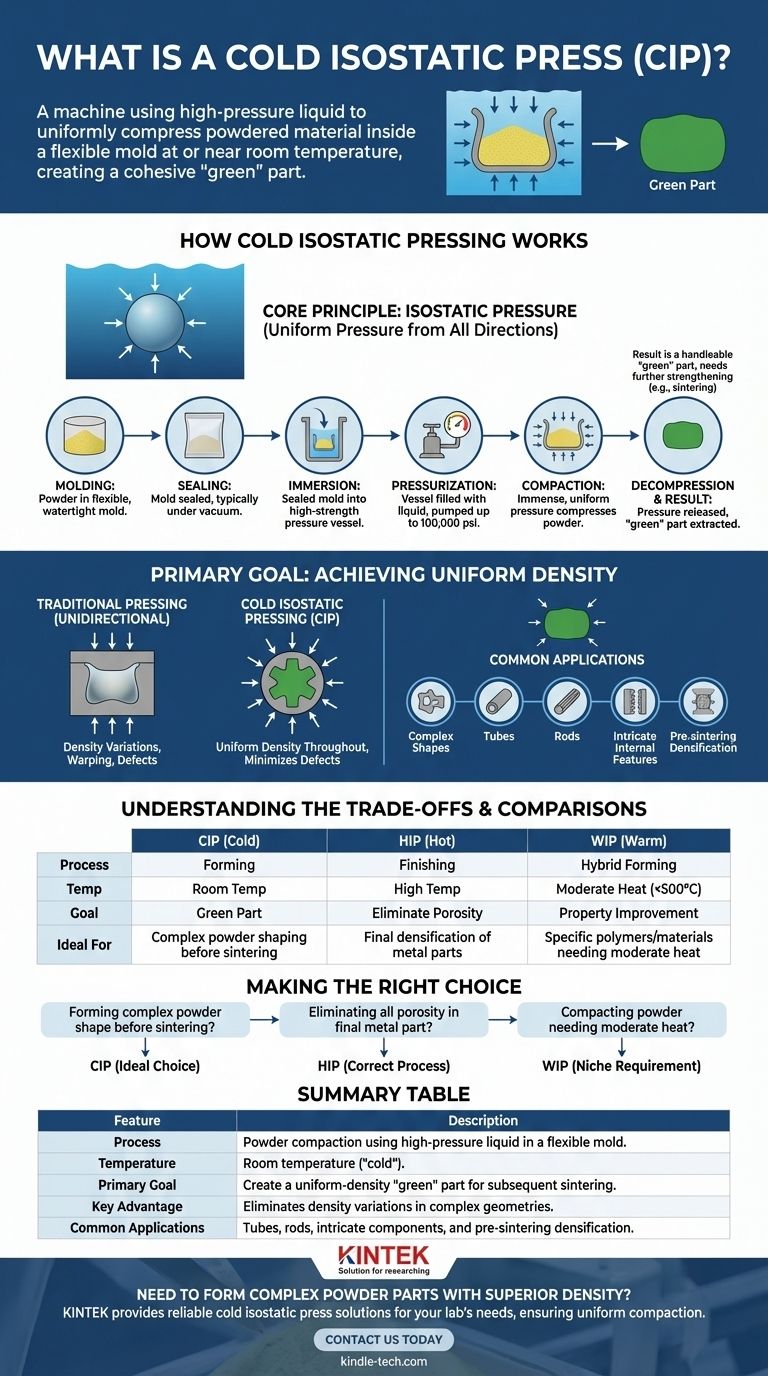

How Cold Isostatic Pressing Works

To understand a CIP, you must first understand the principle of isostatic pressure. This is the foundation of the entire process.

The Core Principle: Isostatic Pressure

Isostatic pressure is pressure that is exerted equally on all surfaces of an object simultaneously.

The simplest analogy is an object submerged deep underwater. The water pressure comes from all directions—top, bottom, and all sides—compressing the object uniformly. A cold isostatic press recreates this phenomenon in a controlled chamber.

The Step-by-Step Process

The CIP process is a straightforward sequence of mechanical actions.

- Molding: The powder material is loaded into a flexible, watertight mold, typically made of an elastomer like polyurethane or rubber.

- Sealing: The mold is sealed, often under a vacuum, to remove any trapped air that could cause defects.

- Immersion: The sealed mold is placed into a high-strength pressure vessel.

- Pressurization: The vessel is filled with a liquid medium—commonly water with a corrosion inhibitor, oil, or a glycol mixture. An external pump increases the fluid pressure, which can reach up to 100,000 psi (or ~690 MPa).

- Compaction: This immense, uniform pressure is transmitted through the flexible mold, compressing the powder particles together from all directions.

- Decompression: The pressure is released, the mold is removed from the chamber, and the newly formed solid part is extracted.

The Result: A "Green" Part

The output of a CIP is not a finished component. It is a "green" or "raw" compact.

This part is dense and solid enough to be handled, machined, or transported, but it has not yet achieved its final mechanical properties. To gain its full strength and density, it must undergo a subsequent high-temperature process, typically sintering.

The Primary Goal: Achieving Uniform Density

The key advantage of CIP is not just compaction, but the quality of that compaction. Uniform pressure creates uniform density.

Why Uniformity Is Critical

In traditional unidirectional pressing (pressing from one or two sides), friction between the powder and the die walls causes density variations within the part. These inconsistencies can lead to warping, cracking, or internal stresses during sintering.

CIP eliminates this problem. Because pressure is applied equally from all sides, it produces a part with exceptionally uniform density throughout, regardless of its complexity. This is crucial for high-performance components.

Common Applications

Cold isostatic pressing is the preferred method for several key manufacturing goals.

It is used to produce parts with complex shapes, such as tubes, rods, or components with intricate internal features that are difficult or impossible to form with rigid dies. It is also used simply to increase the density of a powder preform before it moves to another manufacturing step.

Understanding the Trade-offs and Comparisons

Cold isostatic pressing is one of several isostatic pressing technologies. Choosing the right one depends entirely on your material and your final goal.

Cold (CIP) vs. Hot Isostatic Pressing (HIP)

This is the most critical distinction. CIP is a forming process, used at room temperature to shape powders into a green part.

HIP is a finishing process, used at extremely high temperatures and pressures to eliminate the final voids and porosity in an already-solid part (like a casting or a sintered CIP part) to achieve 100% theoretical density.

Cold (CIP) vs. Warm Isostatic Pressing (WIP)

Warm Isostatic Pressing is a hybrid process. It operates at elevated temperatures, but typically below 500°C—far cooler than HIP.

This moderate heat is used during compaction to promote material diffusion or phase changes in specific polymers or other materials that benefit from it, but the primary goal is still forming a part from powder.

Making the Right Choice for Your Project

Use this guide to determine which process aligns with your objective.

- If your primary focus is to form a complex powder shape before sintering: CIP is the ideal choice for creating a uniform, handleable green compact.

- If your primary focus is to eliminate all porosity in a final metal part or casting: Hot Isostatic Pressing (HIP) is the correct process, as it uses heat and pressure for final densification.

- If your primary focus is to compact a powder that benefits from moderate heat to improve its properties during forming: Warm Isostatic Pressing (WIP) is the specific tool for that niche requirement.

Ultimately, selecting the correct pressing technology is essential for achieving the desired density, shape, and final performance of your component.

Summary Table:

| Feature | Description |

|---|---|

| Process | Powder compaction using high-pressure liquid in a flexible mold. |

| Temperature | Room temperature ("cold"). |

| Primary Goal | Create a uniform-density "green" part for subsequent sintering. |

| Key Advantage | Eliminates density variations in complex geometries. |

| Common Applications | Tubes, rods, intricate components, and pre-sintering densification. |

Need to form complex powder parts with superior density?

KINTEK specializes in lab equipment and consumables, providing reliable cold isostatic press solutions for your laboratory's material processing needs. Our expertise ensures you achieve the uniform compaction required for high-performance components.

Contact us today to discuss how a CIP can enhance your manufacturing process!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is cold isostatic pressing used for? Achieve Uniform Density in Complex Parts

- How does isostatic pressing work? Achieve Perfectly Uniform Density for Complex Parts

- What is the difference between wet bag and dry bag CIP? Choose the Right Process for Your Production Needs

- What is the cold CIP process? Achieve Uniform Density in Complex Powdered Parts

- What are the industrial applications of cold work? Achieve Superior Strength and Precision in Metal Parts

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom

- What is isostatic pressing of ceramics? Achieve Uniform Density and Complex Shapes

- What is the significance of using a cold isostatic press (CIP) to achieve pressureless sintering in LLZO? Enhance Density