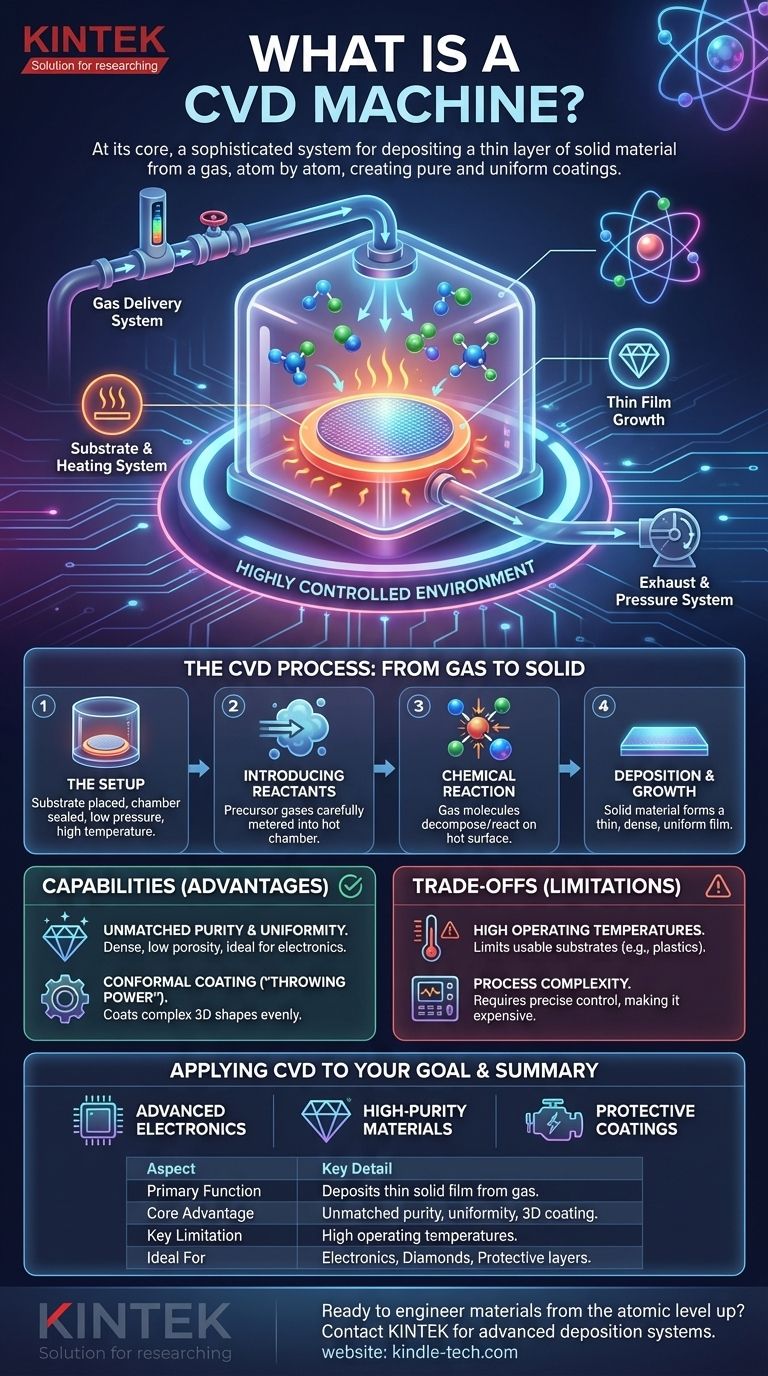

At its core, a CVD machine is the equipment that performs Chemical Vapor Deposition, a sophisticated process for depositing a thin layer of solid material onto a surface from a gas. This technique is less like painting and more like growing a material, atom by atom, allowing for the creation of extremely pure and uniform coatings, such as those used in synthetic diamonds or advanced semiconductor chips.

A Chemical Vapor Deposition (CVD) machine is not a single device but a highly controlled system. Its fundamental purpose is to create a precise environment—managing gas, temperature, and pressure—to trigger a chemical reaction that "grows" a thin film of solid material onto a substrate.

How a CVD System Fundamentally Works

A CVD machine facilitates a chemical process in the vapor phase. Think of it as an advanced oven where gaseous ingredients react in a controlled way to form a solid, crystalline "crust" on a prepared surface.

The Deposition Chamber

This is the heart of the system. It is typically a vacuum chamber that holds the substrate (the material to be coated) and contains the chemical reaction. Its design is critical for ensuring gases flow uniformly.

The Gas Delivery System

This component precisely introduces one or more volatile precursor gases into the chamber. These gases contain the elements required for the final film. For example, to grow a synthetic diamond, a carbon-containing gas is used.

The Substrate and Heating System

The substrate is the foundation upon which the thin film is grown. A heating system brings the substrate to a very high temperature. This thermal energy is the catalyst that breaks down the precursor gas molecules and drives the deposition reaction.

The Exhaust and Pressure System

The system removes byproduct gases and maintains the chamber at a specific pressure, which can range from atmospheric pressure to a near-perfect vacuum. This control is crucial for managing the density and quality of the final coating.

The CVD Process: From Gas to Solid

The entire process is a carefully choreographed sequence designed to build a perfect layer of material. It’s a powerful method for manufacturing materials with properties that are impossible to achieve through other means.

Step 1: The Setup

A substrate, such as a silicon wafer or a synthetic diamond seed, is placed inside the chamber. The chamber is then sealed and brought to the correct low pressure and high temperature.

Step 2: Introducing the Reactants

One or more precursor gases are carefully metered into the hot chamber. The molecules in the gas diffuse towards the heated substrate.

Step 3: The Chemical Reaction

Once the gas molecules reach the hot substrate surface, they decompose or react with each other. The high temperature provides the energy needed to break their chemical bonds.

Step 4: Deposition and Growth

The reaction produces a solid material that deposits onto the substrate, forming a thin, dense film. Over time, this film grows in a highly uniform layer across the entire surface.

Understanding the Capabilities and Trade-offs

While powerful, CVD is not a universal solution. Its strengths are also linked to its primary limitations, making it a specialized tool for high-performance applications.

Key Advantage: Unmatched Purity and Uniformity

Because the film is built from a purified gas, the resulting layers are exceptionally dense, pure, and have low porosity. This is critical for high-performance electronics and materials.

Key Advantage: Conformal Coating ("Throwing Power")

CVD excels at producing uniform coatings, even on substrates with complex, three-dimensional shapes. This ability, known as "throwing power," ensures every peak and valley of an object is coated evenly.

Key Limitation: High Operating Temperatures

The process relies on elevated temperatures to activate the chemical reactions. This requirement means CVD cannot be used on substrates that cannot withstand the heat, such as many plastics or low-melting-point metals.

Key Limitation: Process Complexity

A CVD machine is a complex system requiring precise control over gas flow, temperature, and vacuum. This makes the process and equipment more expensive and demanding than simpler coating methods.

Applying CVD to Your Goal

The decision to use CVD is driven by the need for performance characteristics that other methods cannot deliver.

- If your primary focus is advanced electronics: CVD is essential for its ability to perform selective deposition on patterned substrates, forming the foundational layers of modern microchips.

- If your primary focus is creating high-purity materials: CVD is the definitive method for growing crystalline structures, such as the flawless lattices of lab-grown diamonds from a carbon gas.

- If your primary focus is high-performance protective coatings: CVD's "throwing power" makes it ideal for applying hard, durable, and uniform layers on complex industrial parts like machine tools or engine components.

Ultimately, a CVD machine provides the power to engineer materials from the atomic level up.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Deposits a thin, solid film from a gas onto a substrate. |

| Core Advantage | Unmatched purity, uniformity, and ability to coat complex 3D shapes. |

| Key Limitation | Requires high operating temperatures, limiting usable substrates. |

| Ideal For | Advanced electronics, synthetic diamonds, and high-performance protective coatings. |

Ready to engineer materials from the atomic level up?

A CVD machine is a powerful tool for achieving unparalleled coating purity and performance. Whether your project involves advanced semiconductor fabrication, creating lab-grown diamonds, or applying durable protective layers, the right equipment is critical to your success.

KINTEK specializes in providing high-quality lab equipment and consumables, including advanced deposition systems tailored to your specific research and production needs. Our experts can help you select the perfect solution to enhance your laboratory's capabilities.

Contact KINTEK today to discuss how our CVD solutions can drive your innovations forward.

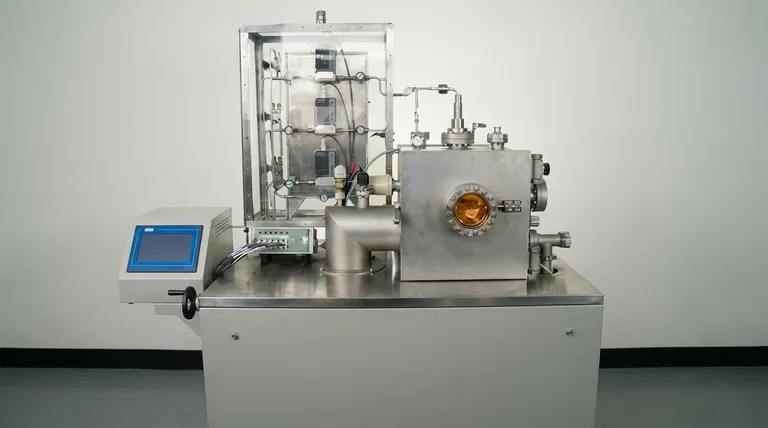

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures