In short, a laboratory mixer is a device designed to combine different materials into a single, uniform substance. It's a foundational tool in scientific research and analysis, ensuring that a sample is perfectly homogeneous before it is tested, measured, or used in an experiment.

The fundamental goal of a laboratory mixer is to overcome the natural tendency of substances to remain separate. It uses energy—whether through shaking, stirring, or high-impact grinding—to create a consistent, homogeneous mixture essential for reliable scientific results.

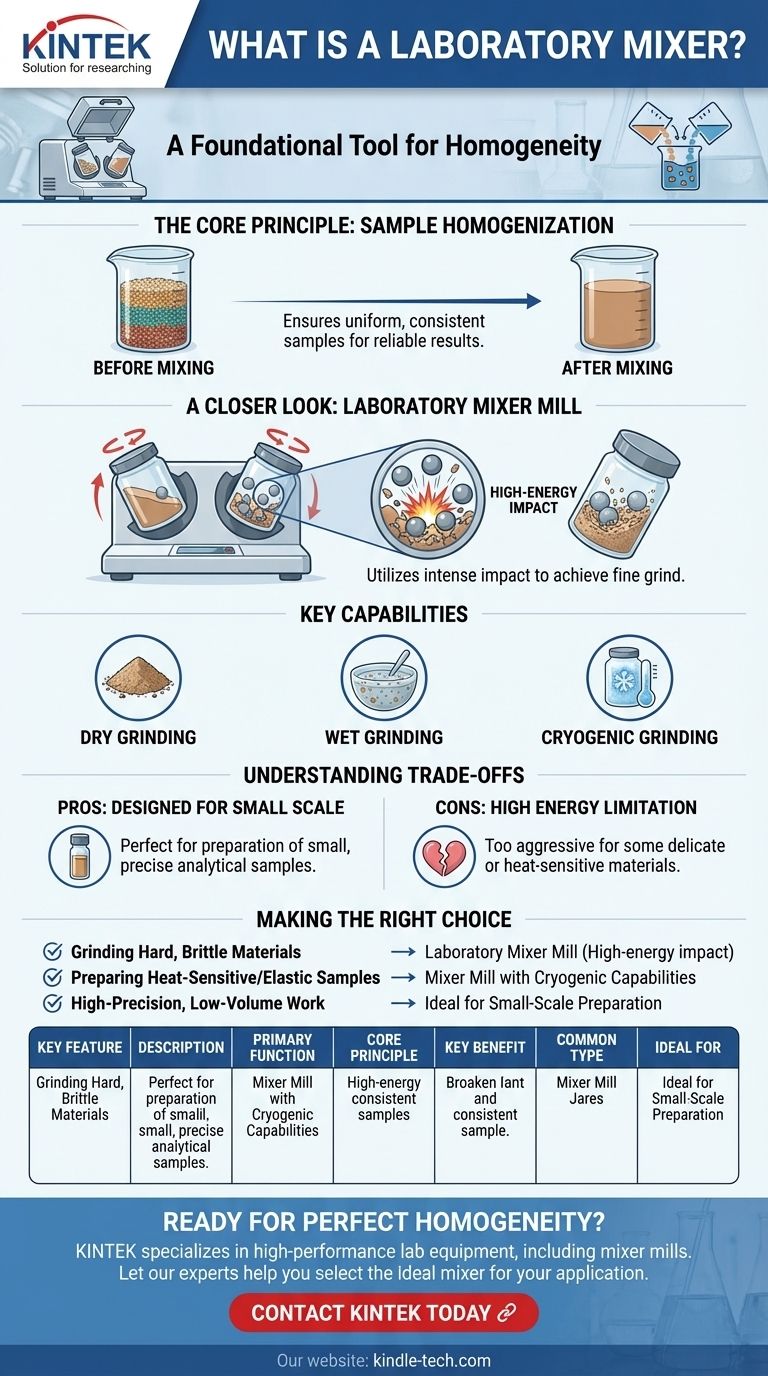

The Core Principle: Sample Homogenization

Why Homogeneity Matters

In any scientific analysis, the portion of a sample being tested must accurately represent the entire batch. If a sample is not properly mixed, results can be inconsistent and unreliable.

A laboratory mixer eliminates this variability. By creating a uniform mixture, it ensures that any two aliquots taken from the sample will have the same composition.

Beyond Simple Stirring

While a simple magnetic stirrer is a form of mixer, the term often refers to more powerful and specialized equipment. This is especially true for solid or difficult-to-mix samples.

These advanced mixers apply significant energy to break down particles and distribute them evenly. One of the most common high-energy types is the laboratory mixer mill.

A Closer Look: The Laboratory Mixer Mill

How It Works: High-Energy Impact

A mixer mill is a specialized type of ball mill designed for preparing very small sample quantities. Its working principle is based on intense energy and physical impact.

The sample is placed into one or more grinding jars along with grinding balls. The jars then rotate and oscillate at high speed, causing the balls to collide with the sample material repeatedly.

This constant, high-energy impact is extremely effective at breaking down particles, resulting in a much faster and finer grind than other milling methods can achieve.

Key Capabilities and Applications

Mixer mills are exceptionally versatile. They are used for dry grinding of hard or brittle materials, wet grinding where a liquid medium is used, and even cryogenic grinding.

Cryogenic grinding involves using a substance like liquid nitrogen to make the sample extremely brittle. This is ideal for materials that are sensitive to heat or are otherwise difficult to reduce to a fine powder, such as plastics or biological tissue.

Understanding the Trade-offs

Designed for Small Scale

The primary advantage of a mixer mill is also its main limitation: it is designed for very small quantities of material. This makes it perfect for sample preparation for analysis but completely unsuitable for bulk or production-level processing.

High Energy Can Be a Drawback

The same high-energy impact that makes the mill so effective can be detrimental to certain delicate samples. For materials whose chemical or physical structure could be altered by intense mechanical force or heat generation (from friction), this method may be too aggressive.

Making the Right Choice for Your Application

- If your primary focus is grinding hard, brittle materials into a fine powder: A laboratory mixer mill is an excellent choice due to its high-energy impact mechanism.

- If your primary focus is preparing heat-sensitive or elastic samples: A mixer mill with cryogenic grinding capabilities is the ideal solution.

- If your primary focus is preparing small, precise sample quantities for analysis: The design of a mixer mill is perfectly suited for this high-precision, low-volume work.

Ultimately, choosing the right laboratory mixer means matching the tool's capabilities to the specific demands of your sample material and analytical goals.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Function | Combines materials into a uniform, homogeneous substance. |

| Core Principle | Overcomes natural separation using energy (shaking, stirring, impact). |

| Key Benefit | Ensures sample consistency for accurate and reliable scientific analysis. |

| Common Type | Laboratory Mixer Mill for high-energy grinding of small samples. |

| Ideal For | Grinding hard, brittle materials or preparing heat-sensitive samples cryogenically. |

Ready to achieve perfect sample homogeneity in your lab?

The right laboratory mixer is critical for reliable, reproducible results. KINTEK specializes in high-performance lab equipment, including mixer mills designed for precise, small-scale sample preparation. Our experts can help you select the ideal mixer for your specific materials and analytical goals.

Contact KINTEK today to discuss your application and ensure your samples are prepared for success!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What function does a high-speed rotor-stator homogenizer perform in biomass processing? Optimize Structural Disruption

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation