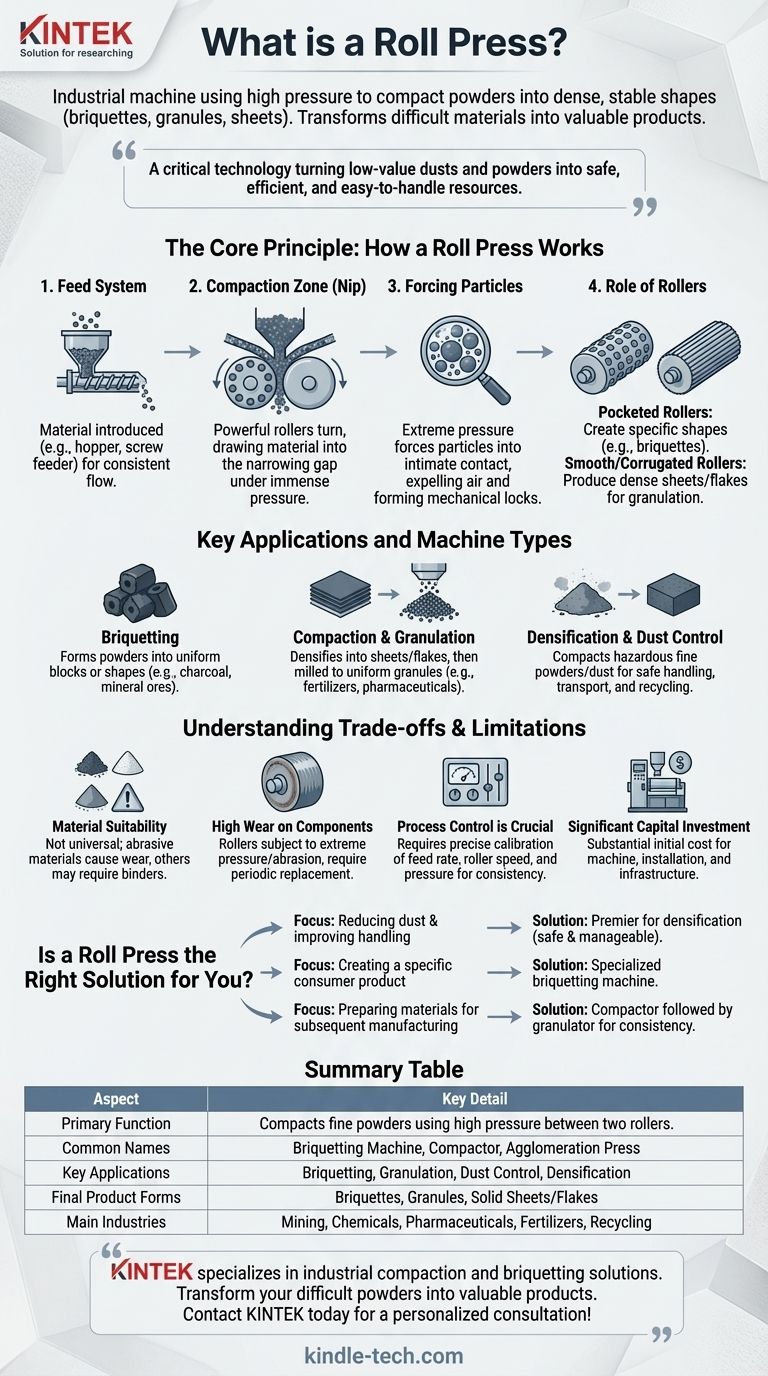

At its most fundamental level, a roll press is an industrial machine that uses high pressure between two counter-rotating rollers to compact loose, fine, or powdered materials. It transforms these difficult-to-handle substances into uniform, dense, and stable shapes like briquettes, granules, or solid sheets. This process is often referred to as agglomeration, compaction, or briquetting.

A roll press isn't just about squeezing a material; it's a critical technology for solving core industrial problems. It turns low-value dusts and powders into valuable, easy-to-handle products, improving safety, logistics, and process efficiency.

The Core Principle: How a Roll Press Works

The operation of a roll press is based on a simple yet powerful mechanical principle. Understanding this process reveals why it is so widely used in industries from mining to pharmaceuticals.

The Feed System

Material is introduced into the machine, typically from a hopper. A screw feeder or gravity system ensures a consistent and controlled flow of the raw powder into the gap between the rollers.

The Compaction Zone

This is the heart of the machine, often called the "nip" region. As the two powerful rollers turn towards each other, they draw the material down into the narrowing gap, applying immense pressure that can reach thousands of pounds per square inch.

Forcing Particles Together

This extreme pressure forces the individual particles of the material into intimate contact. It expels trapped air and mechanically locks the particles together, often forming strong bonds without the need for high temperatures.

The Role of the Rollers

The surface of the rollers defines the final product. Pocketed rollers create specific shapes like the pillow form of charcoal briquettes. Smooth or corrugated rollers are used to produce dense sheets or flakes that can be milled into uniform granules.

Key Applications and Machine Types

While the principle is the same, roll presses are specialized for different outcomes, leading to distinct machine types that solve specific industrial challenges.

Briquetting

This is the process of forming powders into a specific, uniform block or shape. A briquetting machine uses pocketed rollers to produce consumer or industrial products like charcoal briquettes, water softening salt blocks, or mineral ores for smelting.

Compaction and Granulation

Here, the goal is densification. A compactor uses smooth or corrugated rollers to press powders into a hard, solid sheet or flake. This sheet is then milled and screened to produce granules of a specific size, a common requirement for fertilizers, chemicals, and pharmaceuticals.

Densification and Dust Control

Many industrial processes create fine powders or dust (e.g., steel mill dust, fly ash) that are hazardous and difficult to transport. A roll press compacts these materials into a dense, non-dusty form, making them safe to handle, store, or recycle.

Understanding the Trade-offs and Limitations

A roll press is a powerful tool, but it is not a universal solution. Being aware of its limitations is critical for successful implementation.

Material Suitability is Not Universal

Not every material can be successfully compacted. Some materials are too abrasive, causing excessive roller wear. Others lack natural binding properties and may require the addition of a binder (like starch or molasses) to form a stable product.

High Wear on Key Components

The rollers are subjected to extreme pressure and abrasion. They are high-wear components that must be made from incredibly hard materials and will eventually need to be replaced. This represents a significant ongoing operational cost.

Process Control is Crucial

Achieving a high-quality, consistent product requires precise control over several variables. The feed rate, roller speed, and applied pressure must all be carefully calibrated for the specific material being processed.

Significant Capital Investment

Roll presses are heavy, robust industrial machines. The initial purchase price, installation, and associated infrastructure represent a substantial capital investment.

Is a Roll Press the Right Solution for You?

The decision to use a roll press is driven by a clear understanding of your material and your ultimate process goal.

- If your primary focus is... reducing dust and improving material handling: A roll press is a premier solution for densification, turning a hazardous and difficult product into a safe and manageable one.

- If your primary focus is... creating a specific consumer product (e.g., charcoal briquettes): A briquetting machine, a specialized type of roll press, is precisely the tool required for the job.

- If your primary focus is... preparing materials for a subsequent manufacturing step: A compactor followed by a granulator provides the particle consistency and density required for optimal performance in chemical reactors, furnaces, or packaging lines.

Ultimately, a roll press provides a powerful mechanical solution for adding control, safety, and value to bulk powder materials.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Compacts fine powders using high pressure between two rollers. |

| Common Names | Briquetting Machine, Compactor, Agglomeration Press. |

| Key Applications | Briquetting, Granulation, Dust Control, Densification. |

| Final Product Forms | Briquettes, Granules, Solid Sheets/Flakes. |

| Main Industries | Mining, Chemicals, Pharmaceuticals, Fertilizers, Recycling. |

Struggling with hazardous dust or inefficient powder handling? KINTEK specializes in industrial compaction and briquetting solutions. Our roll press machines are engineered to transform your difficult-to-handle powders into valuable, dense products—improving safety, reducing waste, and boosting your operational efficiency. Let our experts help you determine if a roll press is the right solution for your material. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Double Plate Heating Press Mold for Lab

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing