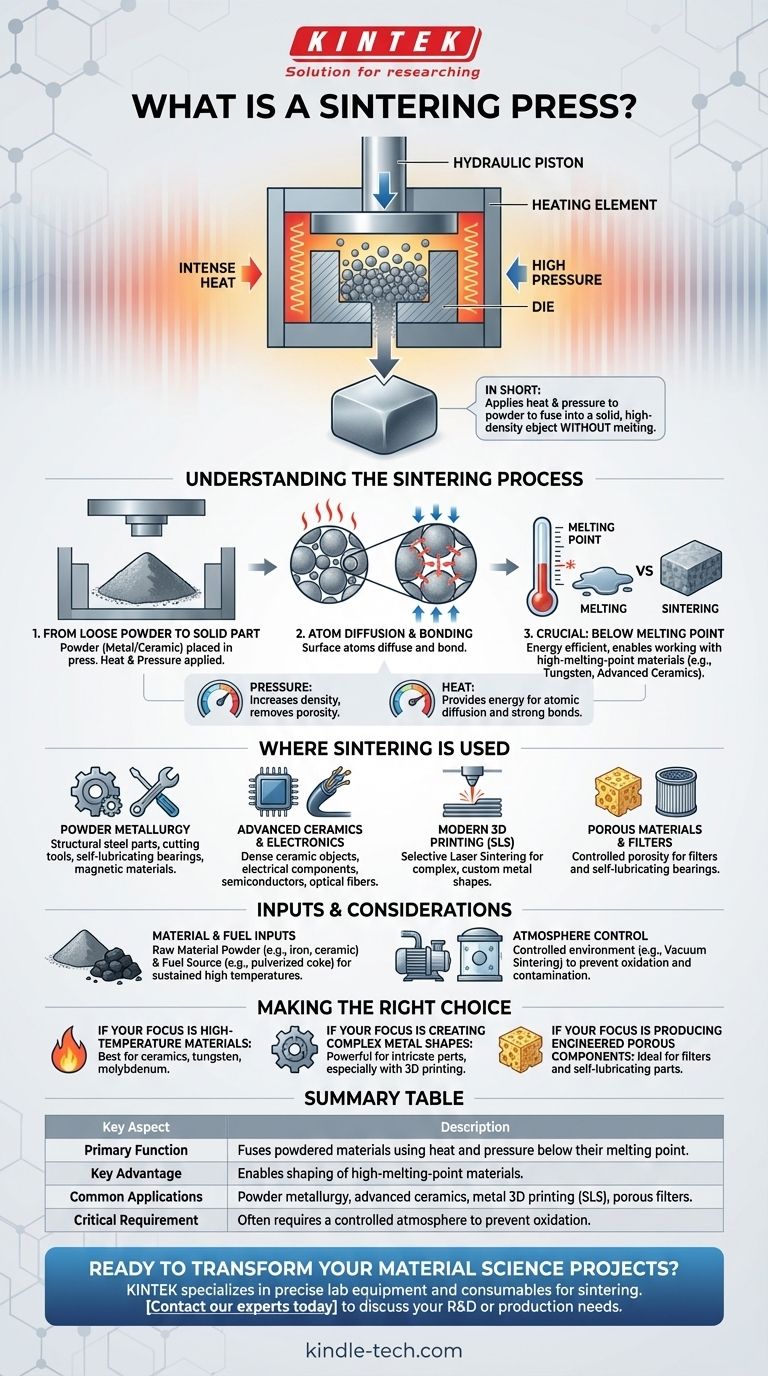

In short, a sintering press is a specialized machine that applies intense heat and pressure to a powdered material. Its purpose is to compact the loose particles and fuse them together into a solid, high-density object without actually melting the material.

The press is the tool, but the core concept to understand is the process it enables: sintering. This manufacturing method transforms simple powders into strong, functional parts, making it possible to work with materials that have extremely high melting points.

Understanding the Sintering Process

Sintering is a foundational technique in materials science and manufacturing. The press facilitates a thermal process that fundamentally changes the nature of the raw material.

From Loose Powder to Solid Part

The process begins with a material in powdered form, such as metal or ceramic. This powder is placed into the press, which then applies high pressure to compact it and high temperatures to heat it.

This combination of forces causes the atoms on the surfaces of the powder particles to diffuse and bond together, creating a solid piece.

Why Not Just Melt It?

Crucially, sintering occurs at a temperature below the material's melting point. This is its primary advantage.

It saves significant energy and is often the only practical way to form parts from materials with exceptionally high melting points, such as tungsten and many advanced ceramics.

The Role of Temperature and Pressure

The sintering press gives engineers precise control over these two key variables.

Pressure squeezes out the porous spaces between particles, increasing the material's density. Heat provides the energy needed for atomic diffusion, which creates the strong bonds that give the final part its structural integrity.

Where Sintering is Used

Because of its unique advantages, sintering is a critical process across a wide range of industries for creating high-performance components.

Powder Metallurgy

This is the science of creating metal parts from powders. Sintering is used to produce everything from structural steel parts and cutting tools to self-lubricating bearings and powerful magnetic materials.

Advanced Ceramics and Electronics

Sintering is the traditional method for creating dense, hard ceramic objects. It's also used to produce electrical components, semiconductors, and even optical fibers where material purity and precise properties are essential.

Modern 3D Printing

The process is a cornerstone of metal 3D printing. Techniques like selective laser sintering (SLS) use a laser to sinter layers of metal powder, building complex, custom metal shapes with remarkable consistency and control.

Porous Materials and Filters

By carefully controlling the sintering process, it's possible to create materials with a specific level of porosity. This is used to manufacture specialized filters or self-lubricating bearings that hold oil within their porous structure.

Understanding the Trade-offs and Requirements

While powerful, the sintering process is not a universal solution. It has specific inputs and considerations that must be managed for successful outcomes.

Material and Fuel Inputs

The process requires two essential components: the raw material powder (like iron or manganese ore) and a fuel source. The fuel, often a solid like pulverized coke, is needed to generate the sustained high temperatures required for diffusion.

Importance of Atmosphere Control

For many high-performance materials, the sintering process must occur in a controlled environment.

A vacuum sintering press, for example, removes atmospheric gases like oxygen before heating. This prevents oxidation and contamination, ensuring the final product has the desired chemical and physical properties.

Making the Right Choice for Your Goal

Sintering is chosen when its specific benefits align with the goals of the final product. Understanding your priority will clarify if it's the correct manufacturing approach.

- If your primary focus is high-temperature materials: Sintering is often the best or only viable method for shaping materials like ceramics, tungsten, or molybdenum.

- If your primary focus is creating complex metal shapes: Sintering, particularly when used in 3D printing, provides a powerful way to manufacture intricate parts without costly machining.

- If your primary focus is producing engineered porous components: The process offers precise control over density, making it ideal for manufacturing filters and self-lubricating parts.

Ultimately, sintering is a transformative technology that allows engineers to build robust, high-performance components from the simplest of starting materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Fuses powdered materials using heat and pressure below their melting point. |

| Key Advantage | Enables the shaping of high-melting-point materials like tungsten and ceramics. |

| Common Applications | Powder metallurgy parts, advanced ceramics, metal 3D printing (SLS), and porous filters. |

| Critical Requirement | Often requires a controlled atmosphere (e.g., vacuum) to prevent oxidation. |

Ready to transform your material science projects?

A sintering press is essential for creating high-density, complex parts from metal or ceramic powders. KINTEK specializes in providing the precise lab equipment and consumables you need to master the sintering process, whether for R&D or production.

Contact our experts today to discuss how our sintering solutions can bring strength, efficiency, and innovation to your laboratory.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is machine press plywood? The Key to Modern Plywood's Strength and Stability

- How does the presence of air in steam affect the hot pressing process? Eliminate Cold Spots and Maximize Efficiency

- What temperature should a hot plate be? Achieve Safe and Precise Heating for Your Lab

- Why is precise temperature control within the supercooled liquid region necessary when using a hot press? (Full Guide)

- What temperature is a heat press lamination? Find the Perfect Heat for a Flawless Finish

- How does the lamination process work? A Guide to Creating Superior Composite Materials

- What is the temperature and pressure of hot pressing? Tailoring Parameters for Your Material

- What is the mechanism of the pressure control system in a hydraulic press during the hot press sintering of MPCF/Al?