At its most fundamental level, a Spark Plasma Sintering (SPS) machine is an advanced manufacturing tool that uses electricity and pressure to rapidly forge powdered materials into dense, solid parts. It functions like a specialized hot press but utilizes a powerful, pulsed direct current that flows through the mold and the powder itself. This direct heating method is exceptionally fast and is the key to creating high-performance materials with unique microstructures that are often impossible to achieve with conventional furnaces.

The core innovation of SPS is not just heating, but the speed of heating. By using a direct electrical current to consolidate powders in minutes instead of hours, SPS prevents the undesirable grain growth common in traditional methods, resulting in materials with superior density and strength.

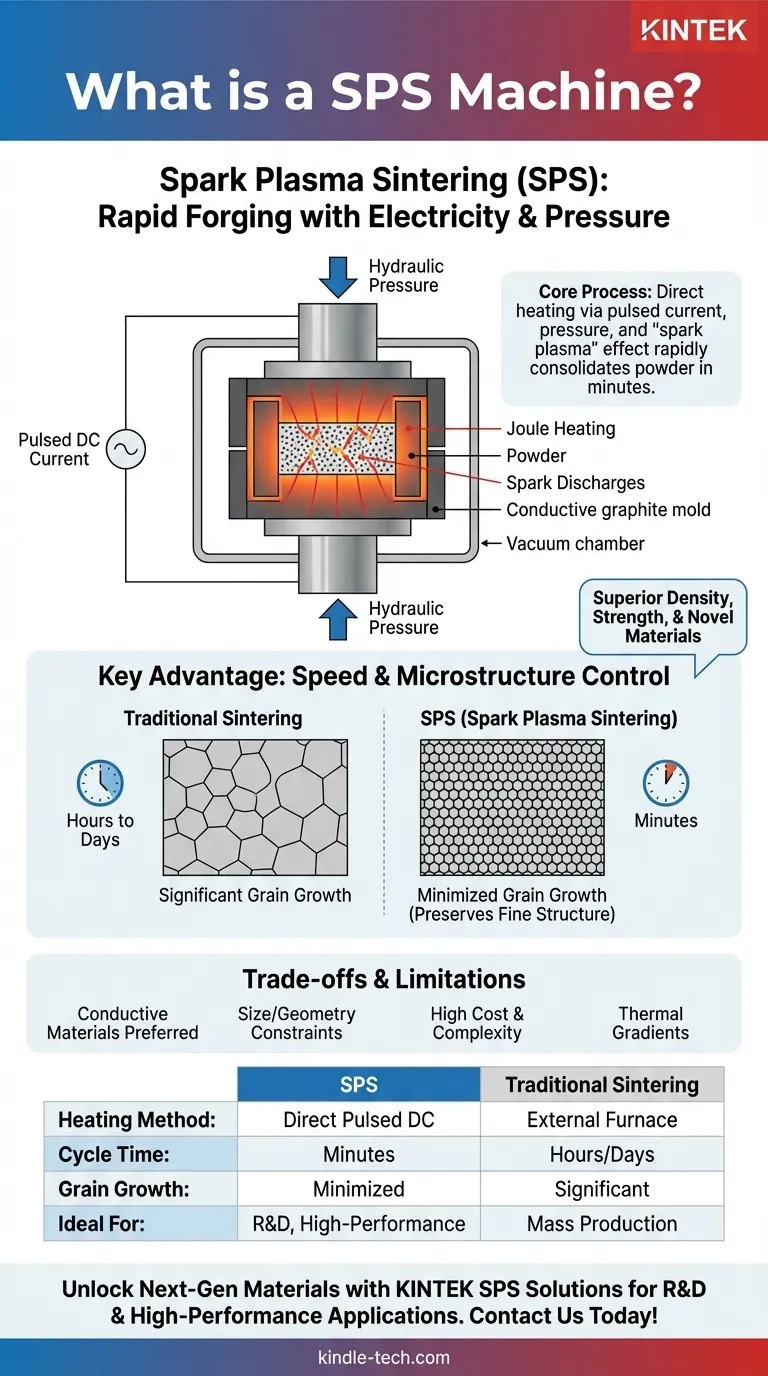

How an SPS Machine Works: The Core Process

To understand what makes an SPS machine unique, we must look at how it combines three critical elements: a conductive die, a pulsed electrical current, and mechanical pressure.

The Physical Setup

An SPS process begins by loading a powdered material into a conductive mold, which is almost always made of graphite. This mold assembly is then placed inside a vacuum chamber between two large electrodes. A hydraulic system applies significant mechanical pressure to the mold.

The Unique Heating Mechanism

Unlike a conventional furnace that heats the chamber, an SPS machine sends a high-amperage, pulsed DC current directly through the electrodes and the graphite mold. Because the mold and (often) the powder are electrically conductive, they heat up incredibly rapidly due to Joule heating. This is the same principle that makes a toaster element glow.

The "Spark Plasma" Effect

The name "Spark Plasma Sintering" suggests that plasma is generated between the powder particles. While the exact mechanism is a subject of scientific debate, it is widely understood that the process generates spark discharges in the gaps between powder grains.

These sparks clean the particle surfaces by stripping away contaminants and oxides. This pristine surface condition dramatically enhances the bonding between particles when pressure is applied.

Densification Under Pressure

As the powder rapidly heats to sintering temperature, the applied mechanical pressure forces the particles together. The combination of clean surfaces, intense heat, and high pressure causes the material to consolidate into a solid, highly dense part in a very short amount of time—often just a few minutes.

The Key Advantage: Speed and Microstructure Control

The primary reason to use SPS over other methods lies in its ability to control the final material's internal structure, or microstructure.

Preventing Grain Growth

In traditional sintering, long heating times allow the individual crystals, or grains, within the material to grow larger. For many advanced applications, larger grains are undesirable as they can reduce strength and hardness.

The extreme speed of the SPS process densifies the material before the grains have a chance to grow. This preserves the fine-grained, or even nano-structured, nature of the starting powder, leading to superior mechanical properties.

Enabling Novel Materials

By inhibiting grain growth and avoiding equilibrium states, SPS allows for the creation of materials that simply cannot be made otherwise. This includes advanced ceramics, functionally graded materials, and metal matrix composites with enhanced performance characteristics for aerospace, defense, and medical applications.

Understanding the Trade-offs and Limitations

While powerful, SPS technology is not a universal solution. Its application comes with specific constraints and considerations.

Material and Geometry Constraints

SPS works best with materials that are at least partially electrically conductive. While insulating materials like some ceramics can be sintered, it requires specialized mold designs to ensure proper heating. Additionally, the size and shape of the final part are limited by the graphite molds, which are typically simple cylinders.

Cost and Complexity

SPS machines are sophisticated and expensive pieces of equipment. They require more operational expertise than conventional furnaces and are best suited for high-value applications where the performance benefits justify the cost.

Thermal Gradients

The extremely rapid heating can sometimes create temperature differences, or gradients, across a large part. Managing these gradients is critical to ensure the final component is uniform and free of internal stress.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on the desired outcome for your material. SPS is a specialized tool for demanding applications.

- If your primary focus is high-performance components: SPS is an exceptional choice for creating dense, fine-grained materials with superior strength, hardness, and other mechanical properties.

- If your primary focus is rapid research and development: SPS is invaluable for its ability to quickly produce test samples of novel materials and alloys, drastically shortening development cycles.

- If your primary focus is mass production of simple parts: Traditional, lower-cost methods like conventional sintering or hot pressing are often more economical for applications that do not require elite material properties.

Ultimately, an SPS machine empowers engineers and scientists to create next-generation materials by controlling their structure at the microscopic level.

Summary Table:

| Feature | SPS Machine | Traditional Sintering |

|---|---|---|

| Heating Method | Direct pulsed DC current (Joule heating) | External furnace heating |

| Cycle Time | Minutes | Hours to days |

| Grain Growth | Minimized (preserves fine/nano-structure) | Significant (larger grains) |

| Key Advantage | Superior density & strength; novel materials | Cost-effective for simple parts |

| Ideal For | R&D, high-performance ceramics & composites | Mass production of standard components |

Ready to unlock the potential of next-generation materials in your lab?

At KINTEK, we specialize in providing advanced lab equipment like Spark Plasma Sintering (SPS) machines that enable rapid, high-performance material fabrication. Whether you're in R&D for aerospace, medical devices, or advanced ceramics, our SPS solutions can help you achieve superior material density and strength while drastically shortening your development cycles.

Contact our experts today to discuss how an SPS machine can transform your material synthesis process and bring your innovative projects to life.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

People Also Ask

- What role does the pressure loading system of a VHP furnace play in Al-Ti composites? Key to Densification.

- What pressurization methods are employed in a vacuum hot pressing furnace? Choose the Right Method for Your Materials

- What are the primary functions of a vacuum hot-pressing furnace in the preparation of Cu-2Ni-7Sn/45 steel composites?

- Why is a vacuum hot pressing furnace used for stainless steel-CNT composites? Unlock Near-Theoretical Density

- How does the temperature control system of a vacuum hot press maintain the nanometer-scale microstructure of copper?

- What is the sintering pressing force? A Guide to Achieving Maximum Part Density

- How does a vacuum hot press furnace achieve the densification of ZrB2–SiC–TaC? Unlock Ultra-High Ceramic Density

- What is the hot pressing technique? Achieve Superior Densification for High-Performance Materials