An ashing furnace is a high-temperature oven designed for one primary purpose: to completely burn off all organic and combustible materials from a sample. This process of controlled combustion, known as ashing, leaves behind only the inorganic, non-combustible residue (ash). This allows for precise analysis of the sample's inorganic content by measuring the change in weight or analyzing the remaining ash.

The core value of an ashing furnace is not just heating a sample, but providing a destructive purification step. It strips away the organic "noise" to reveal a sample's fundamental inorganic composition, which is critical for accurate quality control and material analysis.

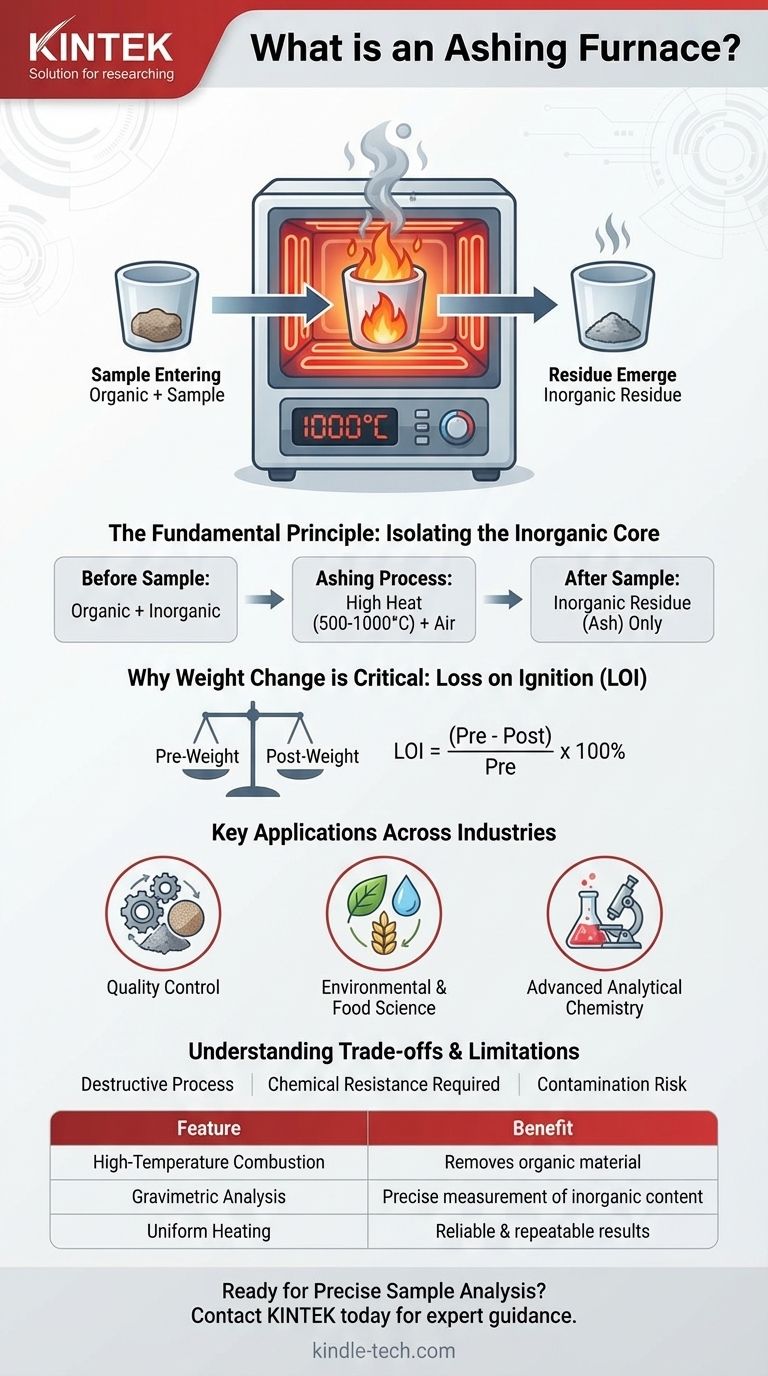

The Fundamental Principle: Isolating the Inorganic Core

To understand an ashing furnace, you must first understand the process it's named for. The goal is to obtain quantitative data about a material by breaking it down to its essential components.

What is "Ashing"?

Ashing is the process of complete combustion in the presence of air. The furnace heats a sample to temperatures high enough (often 500°C to over 1000°C) to cause all organic substances—like carbon-based polymers, plant matter, or oils—to react with oxygen and be expelled as gases.

What remains in the crucible is the inorganic portion, such as minerals, metals, fillers, and salts.

Why Weight Change is the Critical Metric

The most common analysis performed with an ashing furnace is gravimetric. A sample is carefully weighed before it enters the furnace and the resulting ash is weighed again after the process is complete.

This simple pre- and post-measurement yields critical data, such as loss on ignition (LOI). This tells you the total percentage of volatile or organic material that was in the original sample. This is a key quality metric for materials like rubber, plastics, and coal.

The Role of High, Uniform Temperature

For the results to be reliable and repeatable, the furnace's performance is paramount. The control system must provide an accurate temperature, and just as importantly, that temperature must be uniform throughout the chamber.

Inconsistent heating can lead to incomplete combustion, yielding inaccurate and unusable data.

Key Applications Across Industries

The ashing process is a foundational technique used for quality assurance, regulatory compliance, and material science research across a vast range of fields.

Material Composition and Quality Control

In manufacturing, ashing is used to verify product composition. It can determine the filler content in plastics or paper, analyze the ash content of coal for energy calculations, or confirm the composition of rubber compounds.

Environmental and Food Science

Environmental labs use ashing furnaces to measure volatile suspended solids in wastewater effluent as part of regulatory testing. In food science, ashing determines the mineral content of grain and other food products, which is a key indicator of nutritional value.

Advanced Analytical Chemistry

Ashing is a common sample preparation step for more complex analyses. For example, it is used to remove interfering organic matrices before measuring trace elements with techniques like Atomic Absorption (AA) spectroscopy.

Technicians also use ashing furnaces for high-temperature cleaning of lab equipment, such as removing soot from fumed silica grease or burning off residues from ICP torches.

Understanding the Trade-offs and Limitations

While powerful, an ashing furnace is a specific tool with inherent limitations. Understanding these is key to using it correctly.

The Process is Inherently Destructive

The most obvious limitation is that ashing destroys the organic component of your sample. It is not a non-destructive testing method. The information you gain about the inorganic content comes at the cost of the original sample's complete structure.

Chemical Resistance is Non-Negotiable

The combustion process releases a variety of substances, some of which can be chemically aggressive. An effective furnace must have a chamber built from materials that can withstand this chemical attack and resist mechanical weathering over many high-temperature cycles.

Contamination Risk in Trace Analysis

If your goal is to analyze the resulting ash for trace elements, you must consider the furnace itself as a potential source of contamination. The chamber materials must be inert and not leach elements into your sample during the heating process.

Making the Right Choice for Your Analysis

The specific application dictates the most important considerations for the ashing process.

- If your primary focus is quality control (e.g., filler content in plastic): Repeatability is key, so prioritize a furnace with excellent temperature uniformity and accurate controls.

- If your primary focus is environmental compliance (e.g., wastewater analysis): Your furnace and procedure must meet the specific requirements laid out by regulatory bodies for methods like LOI or volatile solids determination.

- If your primary focus is trace element analysis: The furnace is a sample prep tool, so you must ensure its chamber materials are inert and will not contaminate your sample before subsequent analysis.

Ultimately, an ashing furnace provides foundational data by simplifying a complex material into its stable, inorganic components.

Summary Table:

| Feature | Benefit |

|---|---|

| High-Temperature Combustion | Completely removes organic material from a sample. |

| Gravimetric Analysis | Enables precise measurement of inorganic content via weight change (e.g., Loss on Ignition). |

| Uniform Heating | Ensures reliable, repeatable results by preventing incomplete combustion. |

| Versatile Applications | Used in quality control (plastics, rubber), environmental science (wastewater), and food analysis. |

Ready to achieve precise and reliable sample analysis in your lab?

An ashing furnace is essential for accurate quality control, environmental compliance, and material science research. KINTEK specializes in high-performance lab equipment, including ashing furnaces designed for excellent temperature uniformity and durability.

Let our experts help you select the perfect furnace for your specific application. Contact us today to discuss your laboratory needs and discover how KINTEK's solutions can enhance your analytical capabilities.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Do you need to heat the clean crucible before using it? Prevent Thermal Shock and Ensure Process Accuracy

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What is the highest temperature of a furnace? Unlocking the Limits of Extreme Heat

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents

- What are the requisites of refractories? The Four Pillars for High-Temperature Success