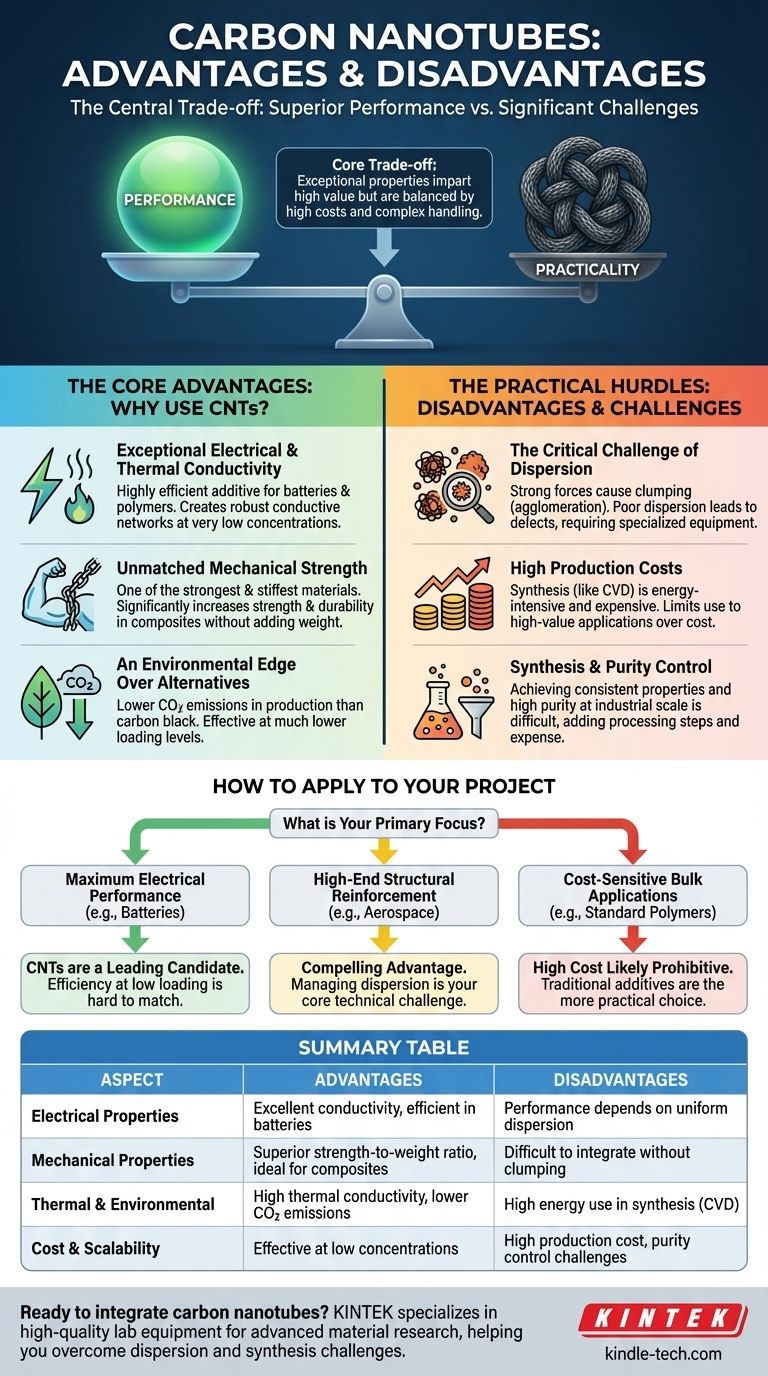

At their core, carbon nanotubes (CNTs) offer a combination of exceptional electrical, mechanical, and thermal properties that far exceed traditional materials. Their primary advantage lies in their ability to impart these characteristics into a host material at very low concentrations, but this potential is often balanced by significant challenges related to high costs and complex manufacturing and handling requirements.

The central trade-off with carbon nanotubes is performance versus practicality. They are a superior additive for enhancing conductivity and strength, but their adoption is frequently limited by high production costs and the technical difficulty of achieving proper dispersion within a material.

The Core Advantages: Why Use Carbon Nanotubes?

The unique cylindrical structure of carbon nanotubes unlocks a range of high-performance characteristics. These properties make them a powerful additive rather than a bulk replacement material.

Exceptional Electrical and Thermal Conductivity

CNTs are excellent conductors of electricity and heat. This makes them a highly efficient additive for applications requiring enhanced conductivity.

Their primary use is as a conductive additive in lithium-ion battery electrodes. A very small amount can create a robust conductive network, improving battery performance and lifespan. This same principle applies to creating conductive polymers and thermal interface materials.

Unmatched Mechanical Strength

On a per-weight basis, carbon nanotubes are one of the strongest and stiffest materials ever discovered. Their tensile strength and elastic modulus are orders of magnitude higher than steel.

When properly integrated into composites like polymers, concrete, or metals, they can significantly increase the material's strength and durability without adding significant weight.

An Environmental Edge Over Alternatives

Compared to other carbon additives, CNTs often present a more favorable environmental profile.

The production of CNTs typically results in lower CO2 emissions per kilogram than for materials like carbon black. Furthermore, they are effective at much lower loading levels, reducing the total amount of additive material required in a composite.

Understanding the Disadvantages and Practical Hurdles

Despite their remarkable properties, CNTs are not a simple drop-in solution. Their use is constrained by several significant real-world challenges that must be addressed in any application.

The Critical Challenge of Dispersion

The single greatest technical hurdle for using CNTs is achieving proper dispersion. Due to strong intermolecular forces, nanotubes tend to clump together, or agglomerate.

If not properly separated and distributed throughout the host material, these clumps act as defects rather than reinforcements, negating any potential benefits. This requires specialized equipment and chemical treatments, adding complexity and cost to manufacturing.

High Production Costs

The synthesis of high-quality carbon nanotubes through methods like Chemical Vapor Deposition (CVD) is an energy-intensive and expensive process.

While costs are decreasing, they remain significantly higher than for conventional additives like carbon black. This price difference often limits their use to high-value applications where performance is the absolute priority over cost.

Synthesis and Purity Control

Producing CNTs with consistent diameter, length, and electronic properties (chirality) at an industrial scale remains a challenge.

This variability can lead to inconsistent performance in the final product. Many applications require a high degree of purity, and removing residual catalysts and amorphous carbon from the final product adds further processing steps and expense.

How to Apply This to Your Project

Your decision to use carbon nanotubes should be driven by a clear understanding of whether their performance benefits justify the cost and processing complexity for your specific goal.

- If your primary focus is maximum electrical performance at low weight (e.g., batteries, conductive films): CNTs are a leading candidate, as their efficiency at very low loading percentages is difficult to match.

- If your primary focus is high-end structural reinforcement (e.g., aerospace composites): The exceptional strength-to-weight ratio is a compelling advantage, but successfully managing dispersion will be your core technical challenge.

- If your primary focus is cost-sensitive bulk applications (e.g., standard polymers, concrete): The high cost of CNTs is likely prohibitive, and traditional additives will almost certainly be the more practical choice.

Ultimately, successfully leveraging carbon nanotubes depends on matching their high performance to an application where that performance overcomes the inherent challenges of cost and integration.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Electrical Properties | Excellent conductivity, efficient in batteries and polymers | Performance depends on uniform dispersion |

| Mechanical Properties | Superior strength-to-weight ratio, ideal for composites | Difficult to integrate without clumping |

| Thermal & Environmental | High thermal conductivity, lower CO2 emissions than carbon black | High energy use in synthesis (CVD) |

| Cost & Scalability | Effective at low concentrations | High production cost, purity control challenges |

Ready to integrate carbon nanotubes into your lab work? KINTEK specializes in high-quality lab equipment and consumables tailored for advanced material research, including CNT applications. Our products help you overcome dispersion and synthesis challenges with precision and reliability. Contact us today to explore how we can support your laboratory's innovation goals!

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

People Also Ask

- What are the practical uses of thin film interference? Control Light for Optics, Security & Manufacturing

- What is the temperature coefficient of graphene? Mastering Its Unique Thermal Contraction

- What are the techniques of carbon nanotubes? Master Synthesis for Your Application

- What are the industrial applications for Silver coatings? Maximize Optical, Electrical, and Catalytic Performance

- What is the structure and properties of carbon nanotubes? Unlocking the Potential of 1D Carbon Allotropes

- What are the disadvantages of RF sputtering? Navigating the Trade-offs of Thin Film Deposition

- What do optical coatings do? Control Light for Superior Optical Performance

- What is the sputtering rate? Master the Key to Controlling Your Thin Film Deposition