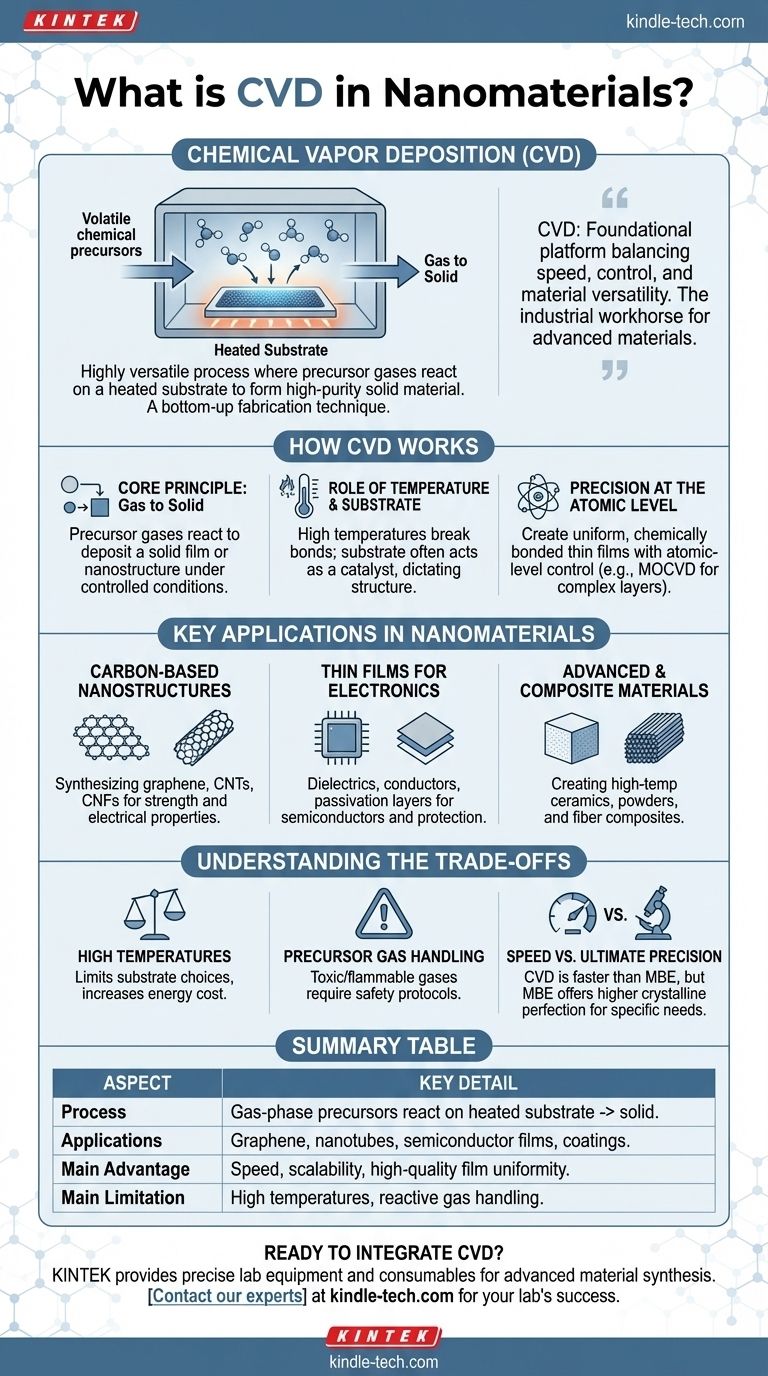

In the context of nanomaterials, CVD stands for Chemical Vapor Deposition. It is a highly versatile process where volatile chemical precursors in a gas phase react or decompose on a heated surface, known as a substrate, to form a high-purity solid material. This bottom-up fabrication technique is fundamental to producing a wide range of nanoscale structures, from single-atom-thick sheets of graphene to complex semiconductor layers.

Chemical Vapor Deposition is not just one technique; it is a foundational platform for manufacturing advanced materials. Its true value lies in its ability to balance speed, control, and material versatility, making it the industrial workhorse for producing many of the most important nanomaterials used today.

How Chemical Vapor Deposition Works

The Core Principle: Gas to Solid

At its heart, CVD is a conversion process. Precursor gases, which contain the atoms of the desired material, are introduced into a reaction chamber.

By carefully controlling conditions like temperature and pressure, these gases are induced to react and deposit a solid film or nanostructure onto a chosen substrate.

The Role of Temperature and Substrate

High temperatures (often several hundred degrees Celsius) provide the necessary energy to break the chemical bonds in the precursor gases.

The substrate is not just a passive surface; it often plays a critical catalytic role in the deposition process and dictates the structure and orientation of the resulting nanomaterial.

Precision at the Atomic Level

While other methods exist, CVD is valued for its ability to create uniform, chemically bonded thin films with atomic-level control over thickness and composition.

Specialized variations, like Metalorganic CVD (MOCVD), allow for the growth of highly complex crystalline layers, which is essential for modern electronics and optoelectronics.

Key Applications in Nanomaterials

Carbon-Based Nanostructures

CVD is the dominant method for synthesizing many revolutionary carbon nanomaterials.

This includes producing large-area, high-quality graphene sheets, as well as carbon nanotubes (CNTs) and carbon nanofibers (CNFs), which are prized for their exceptional strength and electrical properties.

Thin Films for Electronics and Protection

The process is extensively used to deposit a variety of thin films for the semiconductor industry.

These films serve as dielectrics (insulators), conductors, and passivation layers that protect electronic components from the environment. It is also used to create corrosion-resistant and heat-resistant coatings.

Advanced and Composite Materials

Beyond simple films, CVD is used to create complex materials. This includes synthesizing high-temperature ceramics, powders with well-defined particle sizes, and even infiltrating fiber fabrics to create robust fiber composites.

Understanding the Trade-offs

High Temperature Requirements

The high temperatures needed for CVD can limit the types of substrates that can be used, as some materials may melt or deform. This energy consumption also contributes to the overall cost of the process.

Precursor Gas Handling

The chemical precursors used in CVD are often toxic, flammable, or corrosive, requiring sophisticated handling and safety protocols. This can increase the complexity and cost of a CVD setup.

Speed vs. Ultimate Precision

CVD is generally much faster than techniques like Molecular Beam Epitaxy (MBE), which deposits material one atomic layer at a time in an ultra-high vacuum.

However, for applications demanding the absolute highest level of crystalline perfection and interface sharpness, the slower, more controlled nature of MBE may be preferred. CVD offers a powerful balance of speed and high quality, but it is not always the most precise option available.

How to Apply This to Your Project

Choosing a fabrication method depends entirely on your end goal, balancing cost, material requirements, and desired performance.

- If your primary focus is large-scale production of high-quality thin films or carbon nanotubes: CVD is often the most effective and economically viable choice due to its speed and scalability.

- If your primary focus is creating flawless, single-crystal epitaxial layers for high-performance microelectronics: A more specialized and slower method like Molecular Beam Epitaxy (MBE) may be necessary.

- If your primary focus is growing intricate crystalline layers for LEDs or advanced semiconductors: A specialized variant like Metalorganic CVD (MOCVD) will likely be the required tool.

Mastering the principles of CVD is fundamental to leveraging the transformative potential of nanomaterials in nearly every field of modern technology.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Gas-phase precursors react on a heated substrate to form a solid material. |

| Key Applications | Graphene sheets, carbon nanotubes, semiconductor thin films, protective coatings. |

| Main Advantage | Excellent balance of speed, scalability, and high-quality film uniformity. |

| Main Limitation | High temperatures and handling of reactive precursor gases. |

Ready to integrate CVD technology into your lab's workflow? KINTEK specializes in providing the precise lab equipment and consumables needed for advanced material synthesis. Whether you are developing next-generation electronics or high-performance coatings, our expertise supports your innovation from research to production. Contact our experts today to discuss how we can equip your laboratory for success.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the history of chemical vapor deposition? From Light Bulbs to Modern Electronics

- What is the temperature of LPCVD? Optimize Your Thin-Film Deposition Process

- Why is a vacuum ion sputter coater used to apply a gold coating for EDS? Enhance Image Clarity & Chemical Data Accuracy

- What is chemical vapor deposition used for? Creating High-Performance Thin Films for Electronics and More

- What is the function of high-temperature metal filaments in HFCVD? Catalyzing Diamond Growth Success

- What is the application of DC sputtering? A Guide to Cost-Effective Metal Coating

- How many types of sputter are there? A Guide to DC, RF, Magnetron & Reactive Sputtering

- How thick is diamond-like carbon coating? The Critical Balance for Performance